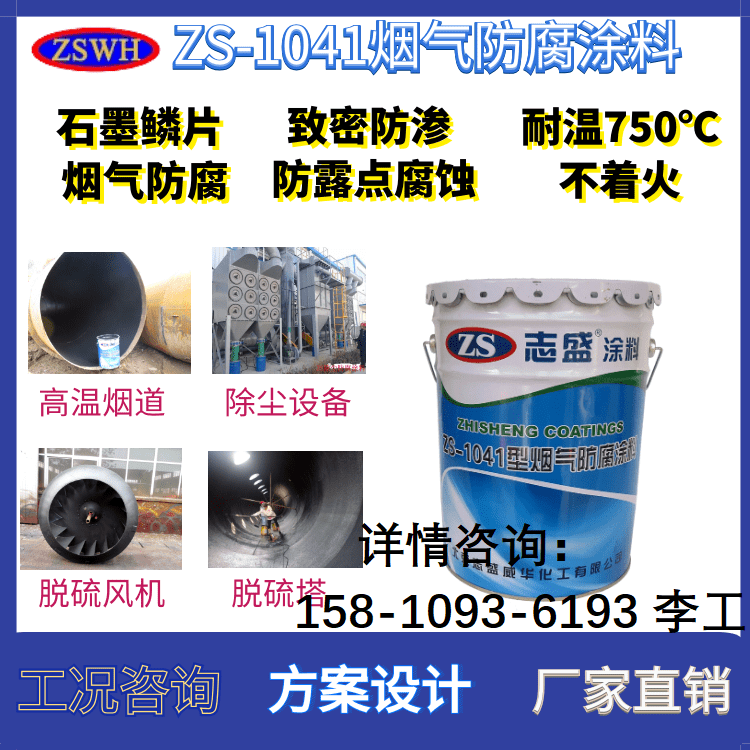

What is Zhumadian ZS-1041 anti-corrosion paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment

Extended Reading

-

What is Zhumadian ZS-1041 anti-corrosion paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Hefei ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Wuhu ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Bengbu ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Huainan ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Maanshan ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Huaibei ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Tongling ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Anqing ZS-1041 anti-corrosion paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment -

What is Huangshan ZS-1041 anticorrosive paint used for? Where can I buy it? Acid resistant paint for environmental protection equipment

News classification

-

Enterprise type: Others -

Business model: Production and processing -

Honors and qualifications: 0 items -

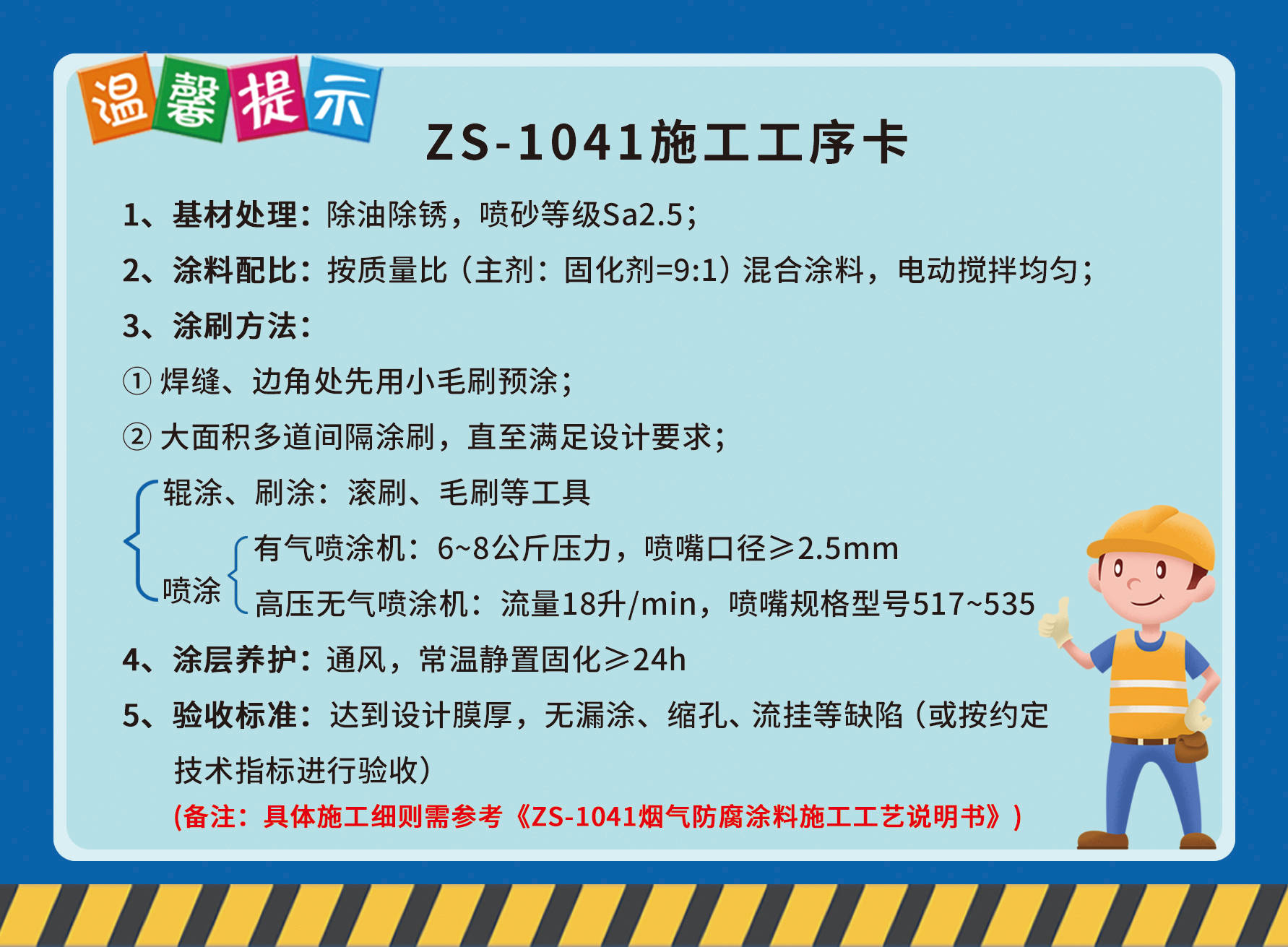

Main business: High temperature resistant coating, high temperature anti-corrosion coating, thermal insulation coating, sunscreen and cooling coating, sewage pool anti-corrosion coating, insulation coating, far-infrared energy-saving coating, anti ice and snow coating -

Address: Tongzhou District, Beijing