Overview of Hankson Precision Filter Element:

Hankson is accurate The filter element is the heart of the filter, as the name implies, the filter element. The filter element is also the main principle of the filter. It is the purification equipment needed to purify the original natural resources and reuse resources. The filter element is generally used in oil filtration, water filtration, air filtration and other filtration industries. except Filter media A small amount of impurities can protect the normal operation of equipment or clean air.

E9 (C Level) | E7 (T Level) | E5 (A Level) | E3 (H Level) | E1 (F Level) | Processing capacity (min) | Outer diameter (mm) | Height (mm) |

sixteen | sixteen | sixteen | sixteen | sixteen | one | forty-two point five | eighty-nine |

twenty | twenty | twenty | twenty | twenty | one point seven two | forty-two point five | one hundred and fifty |

twenty-four | twenty-four | twenty-four | twenty-four | twenty-four | two point nine | sixty point five | one hundred and sixty-seven |

twenty-eight | twenty-eight | twenty-eight | twenty-eight | twenty-eight | four point nine | sixty point five | two hundred and seventy-seven |

thirty-two | thirty-two | thirty-two | thirty-two | thirty-two | seven point two | sixty-eight | three hundred and thirty-five |

thirty-six | thirty-six | thirty-six | thirty-six | thirty-six | eleven | sixty-eight | four hundred and fifty |

forty | forty | forty | forty | forty | fourteen | eighty-three | five hundred and twenty |

forty-four | forty-four | forty-four | forty-four | forty-four | eighteen | eighty-three | six hundred and seventy |

forty-eight | forty-eight | forty-eight | forty-eight | forty-eight | twenty-two | eighty-three | eight hundred and twenty |

level | The solid particles are small to | Filtering precision (PPM) |

Class F (Degreasing and deodorizing filter element) | E1:0.01 | zero point zero zero one |

Level H (very degreasing core) | E3:0.01 | zero point zero zero one |

Grade A (Oil removal core) | E5:0.1 | zero point zero one |

Level T (Vent line filter) | E7:1 | one |

Grade C (Separation filter) | E9:3 | five |

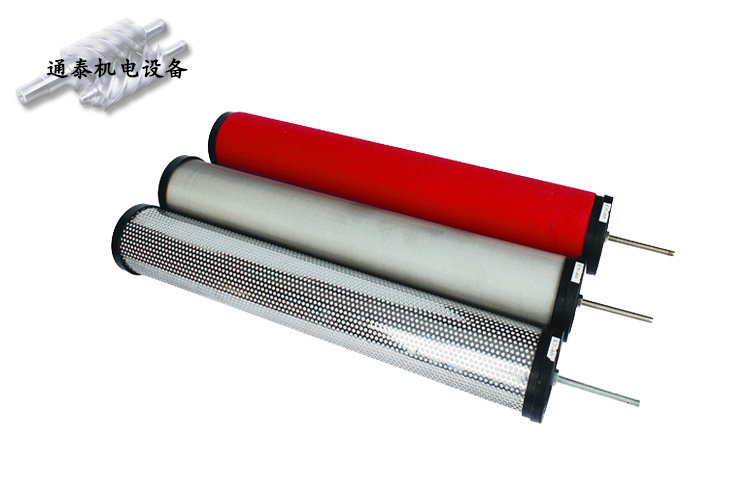

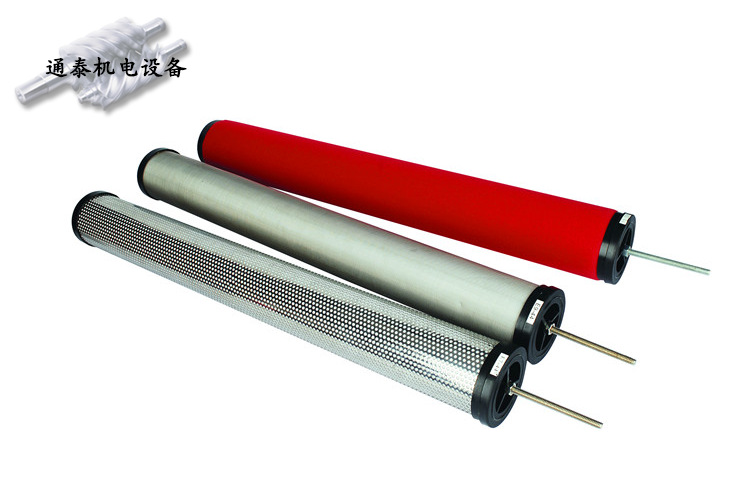

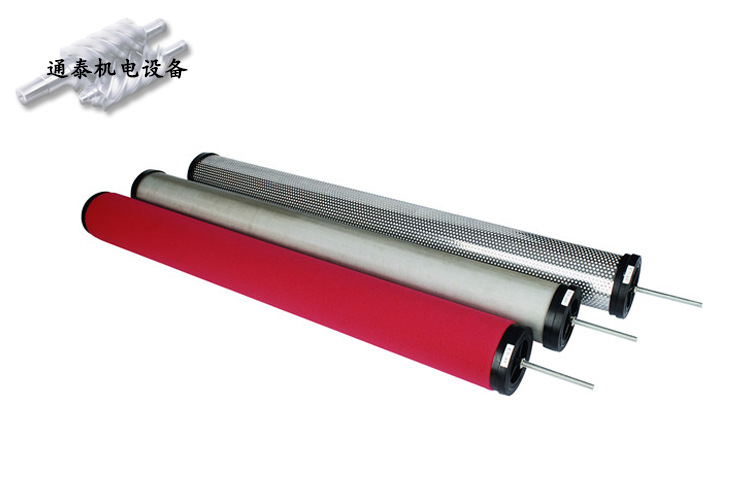

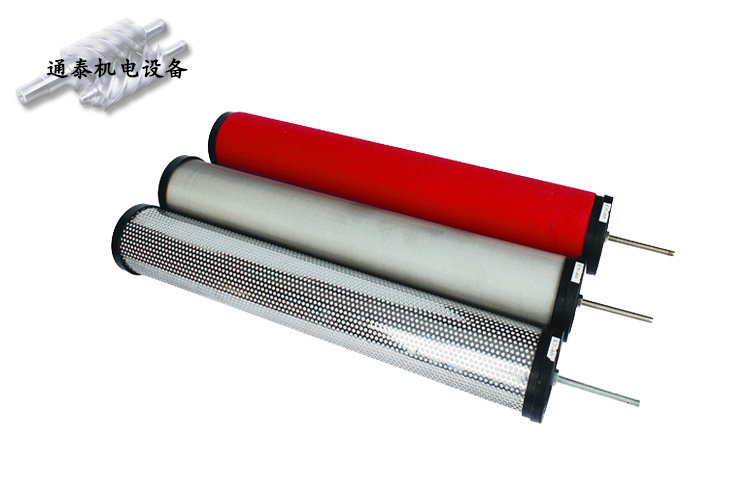

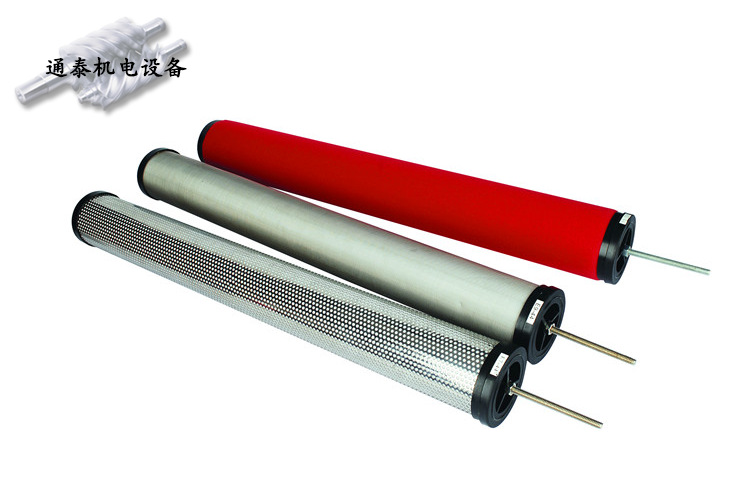

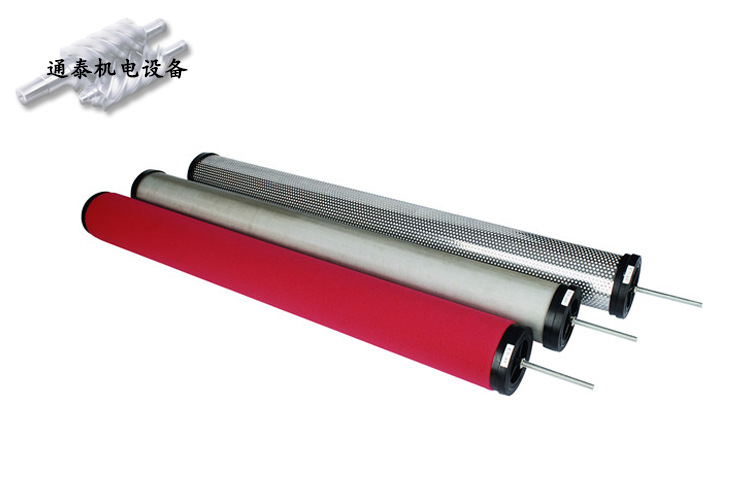

American Hankson Filter Cartridge HANKISON Filter Cartridge

E9 filter element

It is suitable for filtering out a large amount of liquid and 3 micron sized agglomerates, reaching 5ppmw/w with a large residual oil content. Two steel hole tubes at the front stage are used to carry out 10 micron mechanical separation. The second stage deep fiber media filters out 3 micron solid and liquid particles for Air compressor , after the rear cooler and before other filters, for general protection; It is used as pre-treatment device for cold dryer.

E7 filter element

It is suitable for filtering liquid water and oil, and can filter solid particles as small as 1 micron, reaching 1.0ppmw/w with large residual oil powder content. The media filter screens of the first level fiber media are stacked alternately to filter larger particles. The second level, multi-layer epoxy resin Bonding mixed fiber media, deep fiber media, coalescing oil mist and filtering solid particles are used for pretreatment before E5 filter; After the cold dryer and the suction dryer, further improve the air quality.

E5 filter element

It is suitable for coalescing fine water vapor and oil mist. It can filter solid particles as small as 0.01 μ m to reach a large residual oil content of 0.01 ppmw/w, and almost all water, dust and oil are removed. The first level multi-layer fiber media and media filter screen filter out the larger particles, pre filter the second level multi-layer adhesive fiber media before the air enters the second level filtration, filter out the fine agglomerates, and protect them before they are used in the E3 level filtration and dryer. After the cold dryer, ensure that there is no oil in the air.

E3 filter element

It is suitable for coalescing fine water vapor and oil mist. It can filter solid particles as small as 0.01 microns to reach 0.001 ppmw/w, with a large residual oil content. The first stage is for pre filtration and airflow dispersion. The second stage is for multi-layer adhesive fiber media. It can filter out fine agglomerates to protect the air before it is used for E1 filtering and drying machines. After the cold drying machine, it can ensure that there is no oil in the air.

E1 filter element

It is suitable for filtering oil vapor and hydrocarbon vapor that can be generally absorbed by popular carbon. It can filter solid particles as small as 0.01 μ m, playing a later role in filtering. The first level of fine activated carbon powder stable layer can filter most of the oil vapor for some units that must use high-quality air, such as food industry, breathing, aseptic packaging, etc.

Step forward: The filter equipment receives the instruction of replacing the filter element, and changes the filter element after confirming that the system stops running;

second step : Purchase and prepare appropriate filter elements in advance (pay attention to their specifications, materials, sizes, models, etc.), as well as disassembly tools, collecting buckets, rags and other auxiliary facilities;

third step : First, clean the shell of the filter completely and flow out of the operation area;

fourth step : Disconnect the filter to be replaced from the system, slowly open the air outlet on the top of the filter to depressurize it;

fifth step : Empty the material in the filter with special door Open the filter cover to remove the filter element, and use plastic bags and paper boxes to install the filter element;

sixth step : Clean the inside of the filter with cleaning tools and rags; Open the plastic bag at the opening end of the filter element and check whether the O-ring is intact;

seventh step : Install according to the method of flowing in from the outside of the filter element and flowing out from the inside;

eighth step : Wet the socket of the filter element seat of the O-ring with a special wetting agent, hold one end of the O-ring of the filter element, insert the socket of the filter element vertically into the socket of the filter element seat, remove the packing bag of the filter element after insertion, and then use a tool to tighten the filter;

ninth step : Close the drain port of the filter, open the vent valve on the top of the housing to allow the material to enter the housing, and open the outlet valve of the filter until it is fully opened, which means that the replacement is completed;

tenth step : After that, the used tools and cleaning supplies can be cleaned up.

After the above ten steps, we should be roughly familiar with the filter element replacement steps of accurate filters. The basic methods of filter element replacement are applicable to the use of filters of different brands and models.

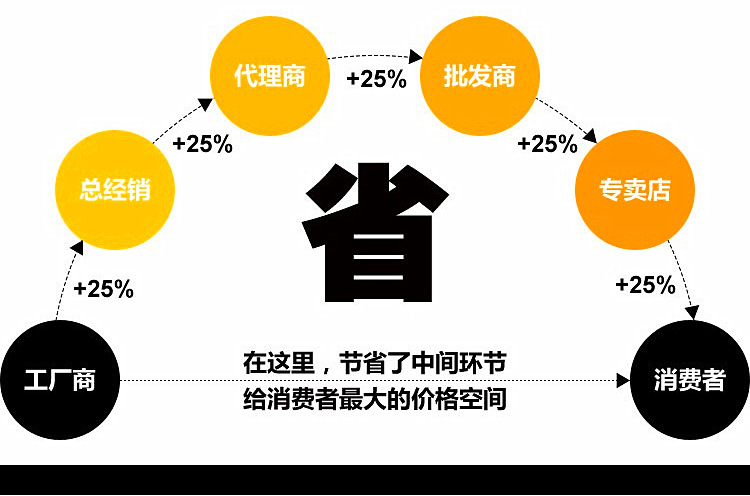

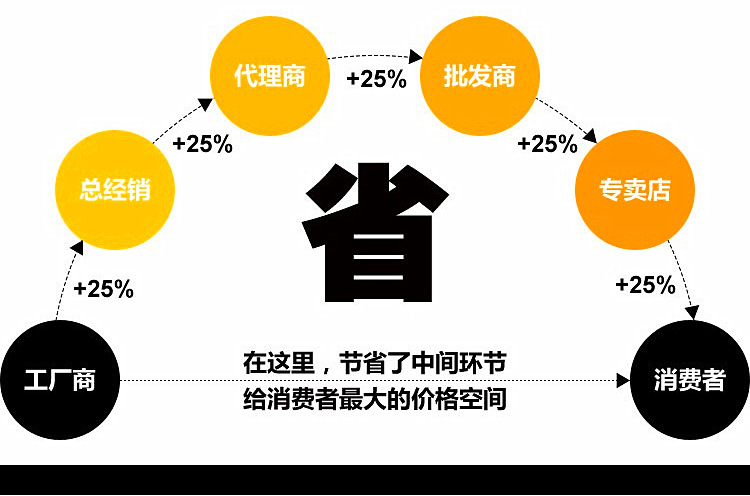

Our company is a professional enterprise engaged in air compressor system design, sales, installation, repair, maintenance, consumables, air purification equipment service of imported air compressors and Hankson accurate filter elements. The company has a professional and experienced engineering and technical team. Since its establishment in 2000, it has been providing customers with advanced products and services, which has won the trust and praise of new and old customers, and has a high reputation in the industry.

Contact: Miss Yang, Mr. Yu

Tel.: * * * 22786706

Email: 22715815@163.com

website: http://www.dg1699.com

http://www.dgxl.com