PP-R

PP-R pipe is also called three type polypropylene pipe and random copolymerized polypropylene. Random copolymerized polypropylene can be extruded into pipes or injected into pipe fittings. Polypropylene random copolymer is also a kind of polypropylene. The basic structure of its polymer chain is modified by adding different kinds of monomer molecules. Ethylene is the most commonly used monomer, which causes changes in the physical properties of polypropylene. Compared with pp homopolymer, random copolymer improves optical properties (increases transparency and reduces haze), improves impact resistance, increases flexibility, reduces melting temperature, and thus reduces hot fusion temperature; At the same time, it is basically the same as homopolymer in terms of chemical stability, water vapor isolation performance and organ sensory performance (low odor and taste). It is used in the fields of blow molding, injection molding, film and sheet extrusion processing as food packaging materials, pharmaceutical packaging materials and daily consumer goods.

1. PP-R classification

PP-R plastic aluminum steady-state pipe The plastic aluminum steady-state pipe product integrates the advantages of metal pipe and plastic pipe, and is widely used in the working conditions with high temperature of transmission medium, special requirements for oxygen resistance and exposed installation, especially for the exposed installation of radiator heating system. Domestic PP-R cold and hot water pipes PPR home installed pipeline system meets the water supply demand under normal use conditions, and can be widely used in various home installed water supply pipeline systems.

2. Common applications of PP-R

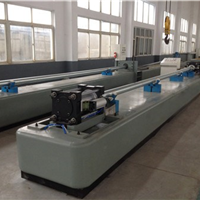

The production process of PP-R pipe is extrusion molding process. First, the PP-R raw material in the feeding hopper enters the extruder by its own weight, and then it is heated, extruded and mixed in the extruder barrel. After being fully plasticized, it is extruded from the extruder die and enters the shaping table. The shaped pipe is cut by the cutter after passing the length determination by the tractor. The pipe is put into storage after passing the inspection. The corresponding pipe fittings are produced by injection molding. Pipe production process: PP-R raw material → vacuum suction feeding → hopper storage → feeding → extrusion molding → cooling and setting → traction → cutting → inspection → warehousing pipe fittings Production process: PP-R raw material → conveying and feeding → hopper storage → feeding → heating and melting → extrusion molding → cooling and setting → mold opening → inspection → warehousing Pipe extrusion parameters: (1) screw speed 5 ~ 38r/min (2) barrel temperature distribution Zone 1 ~ 2 180 ~ 190 ℃ Zone 3 ~ 4 200 ~ 210 ℃ Mould temperature 200 ℃ Traction speed 2 ~ 20m/min Pipe injection parameters: (1) barrel temperature distribution Rear of barrel 160 ~ 170 ℃ Middle of barrel 200 ~ 230 ℃ Front of barrel 180 ~ 200 ℃ (2) Nozzle 170 ~ 190 ℃ (3) The defective products produced during the production of PP-R pipe at 40~80 ℃ can be reused after being broken, which improves the utilization rate of raw materials, reduces production costs and improves economic benefits. Other main uses: 1. The cold and hot water system of the building, including the central heating system; 2. Heating system in the building, including floor, wall panel and radiant heating system; 3. Purified water supply system for direct drinking; 4. Central (centralized) air conditioning system; 5. Industrial piping systems for conveying or discharging chemical media.

3. Development history of PP-R

At present, PP-R products are mainly used for building cold and hot water pipe heating, and are also used in industrial fields such as special medium transportation, hot spring transportation and other fields. As a product with many advantages, PP-R pipeline products occupy a major share in China's water supply and drainage, especially in home decoration projects. However, due to the low concentration of the industry, coupled with the impact of emerging products such as cast iron pipes, China's PP-R pipeline industry has also seen uneven product quality, slow growth and other situations, restricting the healthy development of the industry. The PP-R pipeline industry must strengthen quality self-discipline. On the one hand, while strictly controlling the quality, it should follow the world trend and increase the application of new technologies; On the other hand, we should actively implement the requirements of various national standards to ensure that the quality is worthy of the name. "PP-R has been applied in China for nearly 20 years, and it has been widely promoted for about 15 years. At present, it plays a leading role in building cold and hot water pipeline system. With the price of stainless steel falling back, PP-R will face strong market competition in building cold and hot water system in the next few years. Therefore, In order to maintain its leading position, PP-R must improve its performance and open up new application markets. Ethylene is the most commonly used monomer, which causes changes in the physical properties of polypropylene. Compared with pp homopolymer, random copolymer improves optical properties (increases transparency and reduces haze), improves impact resistance, increases flexibility, reduces melting temperature, and thus reduces hot fusion temperature; At the same time, it is basically the same as homopolymer in terms of chemical stability, water vapor isolation performance and organ sensory performance (low odor and taste). It is used in the fields of blow molding, injection molding, film and sheet extrusion processing as food packaging materials, pharmaceutical packaging materials and daily consumer goods.

4. PP-R business opportunity

-

Zhongtian Pipe ppr Pipe

Zhongtian Pipe ppr Pipe

-

Supply PPR cold and hot water

Supply PPR cold and hot water

-

Hebei ppr pipe

Hebei ppr pipe

-

Supply to South Asia UP

Supply to South Asia UP

-

Ppr hot spring insulation pipe

Ppr hot spring insulation pipe

-

Bainiu factory spot direct sales

Bainiu factory spot direct sales

-

PVC/PPR pipe

PVC/PPR pipe

-

Supply of aluminum alloy plastic lining

Supply of aluminum alloy plastic lining

-

Supply various models of PP

Supply various models of PP

-

Supply PPR pneumatic ball

Supply PPR pneumatic ball

6. PP-R News

-

Generation Z has grown up gradually, and the epidemic has been rampant again and again... All kinds of signs indicate that "home decoration" is no longer just a traditional shelter from wind and rain [Detailed]

-

Since its establishment, Rongshida has always paid attention to improving and perfecting the modern enterprise management mode and marketing network operation mechanism. The company adheres to the corporate culture of "zero defect management" of Rongshida Electronics and Electrical Appliances Group to [Detailed]