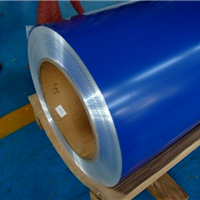

Color coated plate

catalog

-

1. Classification of color coated plate products -

2. Common application of color coated plate -

3. Development history of color coated plate -

4. Business opportunity of color coated plate -

5. Color coated plate brand -

6. Color coated plate news -

7. Color coated board enterprises -

8. Quotation of color coated plate -

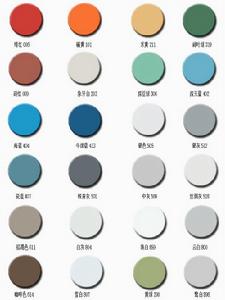

9. Color coated plate atlas

1. Color coated plate classification

2. Common application of color coated plate

3. Development history of color coated plate

4. Business opportunity of color coated plate

-

Supply color coated steel plate, plated -

Supply Shandong Guanzhou Color Coating -

Supply Foshan Anshan Iron&Steel Co., Ltd. for galvanizing -

Supply * * * Baoshimang -

Supply of color coated boards for household appliances, -

Shang Xingzong inherited the color painting scroll, -

Supply color coated plate -

Xingtai self built color steel structure -

Supply Hubei Baosteel color coating -

Baotou color coated plate manufacturer

5. Color coated plate brand

6. Color coated board news

-

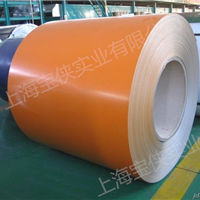

Today's price of color coated plate - how much is it per ton - Boxing color coated plate manufacturer Color coated plate, also known as color steel plate, color coated roll. Color coated plate The base plate is galvanized steel plate, which is coated with paint and then baked. Light weight, elegant appearance and corrosion resistance .. [Detailed] -

More than 100 tons of high-strength antibacterial color coated plates from Hangang Cold Rolling Plant will be exported to the United States Recently, the color coated plate production line of Hangang Cold Rolling Plant has successfully produced more than 100 tons of high-strength antibacterial color coated plates. After inspection, all indicators meet the standard requirements, and the products will be exported to the United States for food packaging. [Detailed]

7. Color coated board enterprises

-

Liaocheng Haoyu Color Coating Co., Ltd Liaocheng, Shandong Main products: color coated roll profiled plate chrome plated plate -

Hebei Yanbo Lottery Coating Industry Co., Ltd Qian'an, Hebei Main products: color coated plate, galvanized plate

8. Quotation of color coated plate

Related information

-

Batch production of ultra wide and ultra thick color coated plate in Hangang Cold Rolling Plant -

Color coated plate of Hebei Iron and Steel Hangang Cold Rolling Plant is favored by the market -

Tai'an hundred billion color coated plate industrial cluster enters a good situation -

Hebei Tangshan Iron and Steel Co., Ltd. Successfully Developed a New Type of Equal Thickness Color Coated Plate -

Masteel Color Coating Plant: the first steel plant with product quality insurance in China -

On May 31, Shenzhen Huamei Board issued price adjustment policy for color coated roll