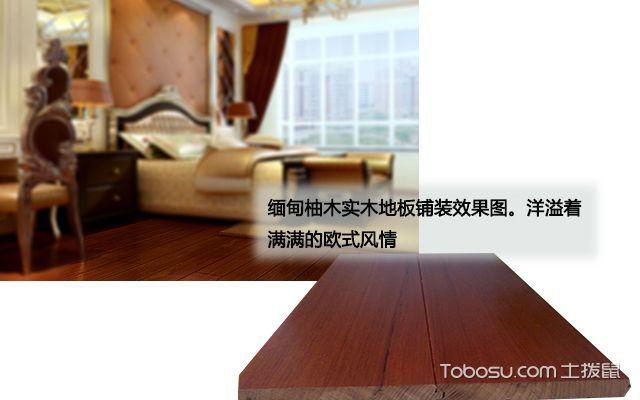

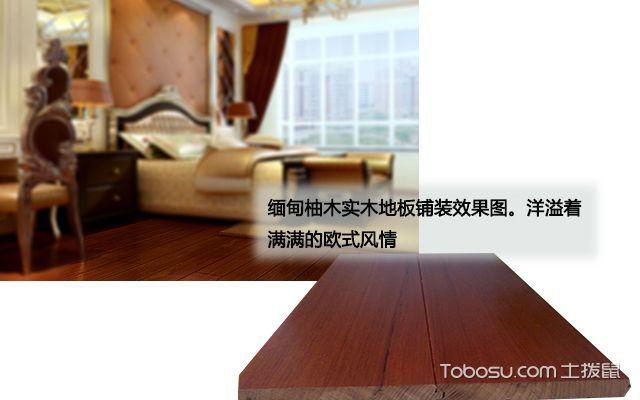

Chinese traditional culture worships rosewood culture, while in western culture, teak is included in the category of worship. European and American countries believe teak is a better wood and is widely used. With the increasing internationalization of China's culture, the higher the openness to the world, the higher people's awareness of teak. Myanmar teak overcame Solid wood flooring Common defects such as easy deformation, cracks and large shrinkage, and release its own woody fragrance, showing natural charm.

Driven by interests, there are many fake solid wood floors in the market. It really takes some effort to buy a real Myanmar teak solid wood floor in the market. In this issue, we will evaluate a Myanmar teak solid wood floor: Dawson Ginger Myanmar teak solid wood floor, the market price is 1050 yuan/㎡ 。 In this evaluation, we found that this teak floor has excellent antifouling performance, but its high temperature resistance makes us a little embarrassed. Compared with the round bean solid wood floor, the high temperature resistance of Dasenginger's floor is indeed lacking! So, what about the other properties of this Myanmar teak solid wood floor? Is it worth buying?

Opening point

In the evaluation of the round bean solid wood floor, although the high temperature resistance did not get five stars, there were no serious problems after being burned by cigarettes. In contrast, the performance of Myanmar teak solid wood floor would be much worse.

Similarly, after the cigarette was burned out, we observed the changes of the burned part of the solid wood floor, and wiped the ashes with a cloth, but there were still black spots that could not be wiped off, and there were still some ashes embedded in the surface cracks that could not be wiped off. In addition, some bubbles caused by high temperature burning can be clearly seen at the burning part. Compared with the test of round bean solid wood floor, the high temperature resistance performance of Myanmar teak is even worse. These problems can only show that the high temperature resistance of this Burmese teak floor is very weak. Therefore, if you choose this floor, you should avoid dropping cigarette butts on the floor or contacting other high temperature sources in daily use to prevent damage.

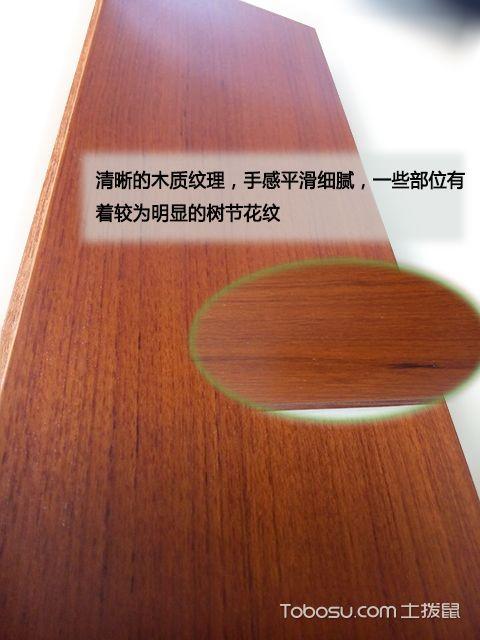

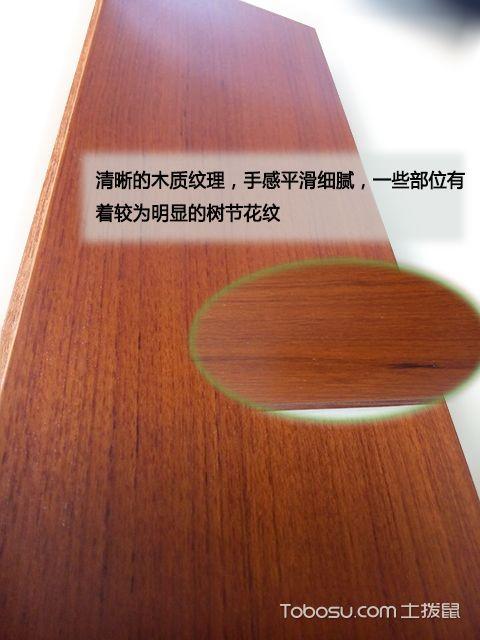

Part 1 Appearance

1.1 Appearance impression

This teak floor is full of oil and bright wood, full and classic color, very delicate hand feel, neat and meticulous texture, and gives off a noble temperament. Therefore, if it is used to create European classical style, it should be a good choice. On the one hand, teak flooring has always been loved by the West, and on the other hand, it originally contains the beauty of natural elegance.

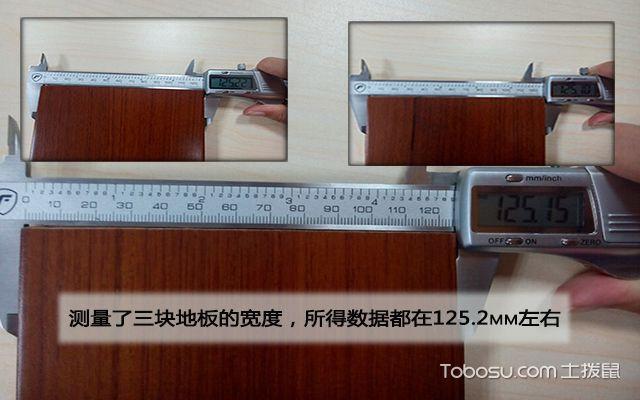

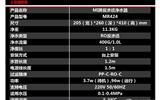

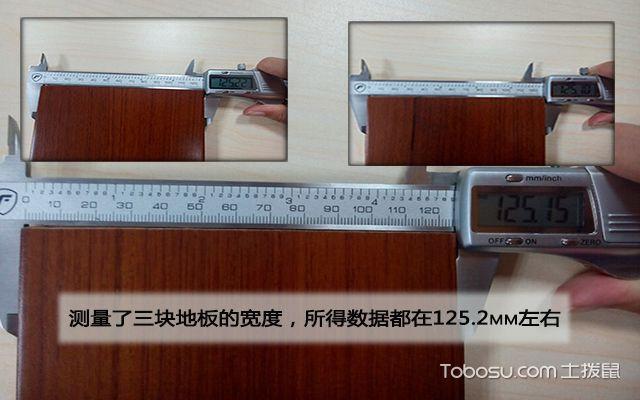

1.2 Width measurement

The width given by the manufacturer is 125mm. We measured the three floors with vernier calipers, and the data obtained are all about 125.2mm, of which the error deviation is about 0.2mm. The standard deviation of solid wood floor width in China is ≤ 0.30mm, so the size deviation of this floor width is in line with the standard.

1.3 Thickness measurement

Also use vernier caliper to measure the thickness of the floor. The reading is 18.12mm, which is only 0.12mm error compared with the value of 18mm given by the manufacturer. The deviation is too small to affect the paving effect of the floor, and there will be no obvious discomfort when people step on it.

For this kind of small floor, due to the need for multiple floors to be spliced when paving, there are many joints, and the probability of concealing dirt is also increased. The owner will be hard to clean, but the small and uniform paving effect is very good, stable, and not easy to deform.

Part 2 Details

2.1 Process evaluation

Dawson Ginger Myanmar teak solid wood floor has a lasting and classic color, golden yellow brown, demonstrating classical charm. We can see that the floor texture is very beautiful, the ink lines are smooth and natural, and there is a faint fragrance overflow, and the natural style is natural. However, when viewed from the side, it is found that the side process is not perfect, the lines are rough, stiff, and not neat enough. If you touch them with your hands, you can feel the burrs scraping your hands.

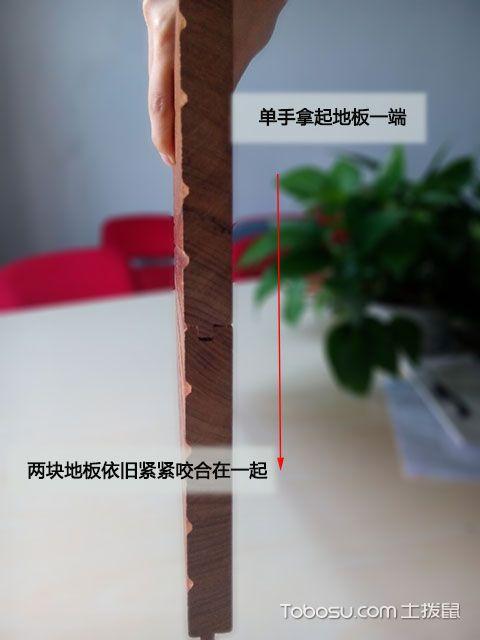

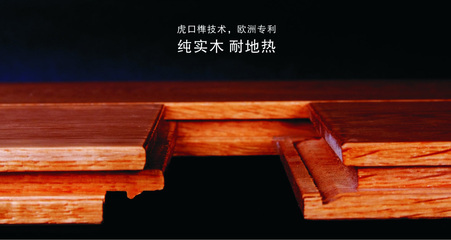

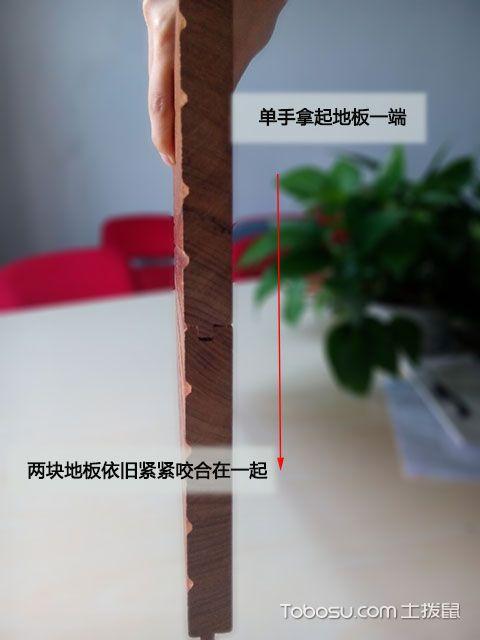

2.2 Floor connection mode

The floor adopts tongue and groove connection, which has high stability, good sealing and convenient operation. We spliced the two floors in person, which is not difficult to operate, but the notch is not smooth and tidy enough, leading to the connection is not compact enough, and we can see from the picture that they are not satisfied with each other.

In order to test the firmness of the splicing, we lifted one side of the floor, and the floor was steadily and vertically downward without detachment. It can be seen that the splicing of this floor is very firm. Compared with the splicing of round bean solid wood floor, the effect is much better.

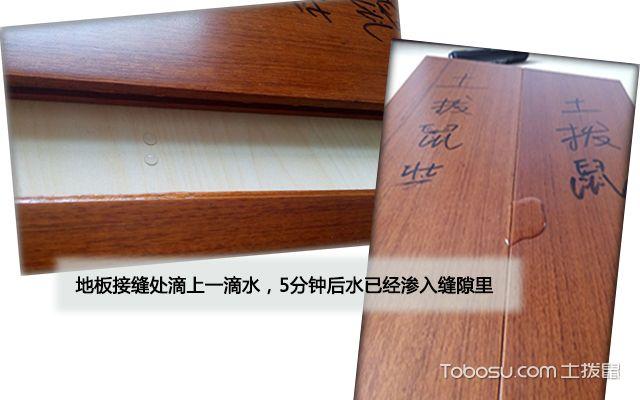

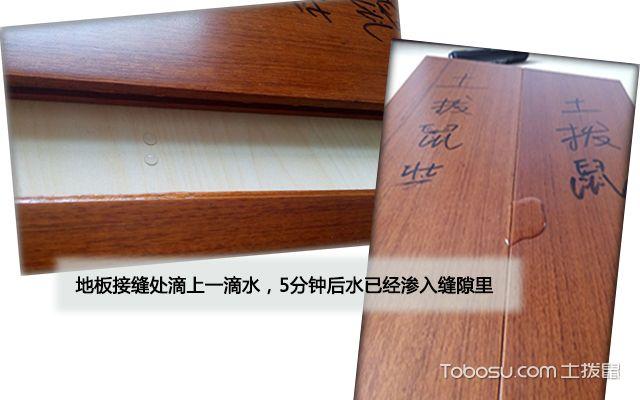

We tested the tightness of this floor splice by dripping water at the seam. Five minutes later, the floor was disassembled. Not only was there water stains at the dripping place, but most of the notches were stained with water stains, indicating that the splice was not tight enough. However, this is not necessarily a bad thing, because the floor will deform according to the temperature and humidity of the environment. If the floor is spliced too tightly, it will bulge when it expands, and if it is too loose, it will shrink into a larger gap.

2.3 Back

The workmanship of the back is good, which can explain whether the merchants are careful in design. In general, we need to evaluate whether there is a logo on the back of the floor, whether there is a moisture-proof substrate, and what designs can help stabilize the pavement. By observing the back of the floor, we clearly saw the logo of the business and laid a layer of moisture-proof substrate. Because the surface is rough, the friction between the floor and the ground is increased, and the pavement will be more stable.

Part 3 Performance Test Diagram

3.1 Pollution resistance test

The test can prove that this solid wood floor is also very stain resistant. Like the round bean solid wood floor, it has a strong defense against stains.

In life, we often rub oil stains on the floor. In order to further evaluate the stain resistance of this Burmese teak floor, we use pepper oil for testing.

After standing for 10 minutes, wipe with a paper towel, and the oil stain is wiped clean, leaving almost no residue. If you can easily deal with chili oil, you can basically face the dirt you often encounter in daily life without pressure.

3.2 Skid resistance test

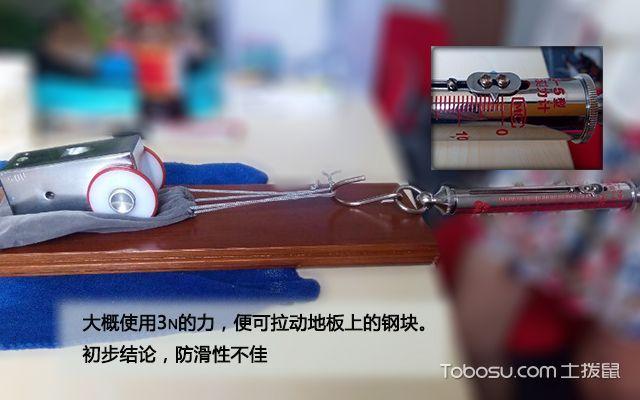

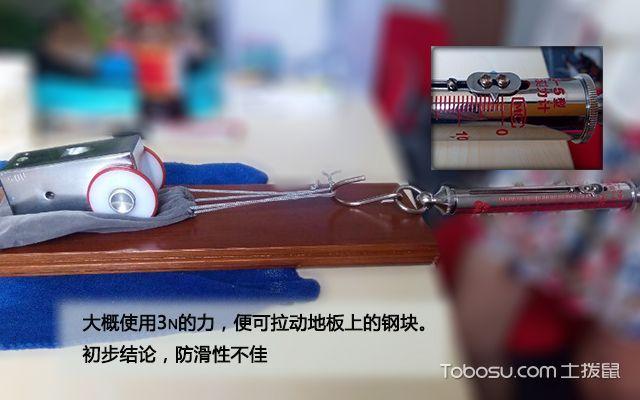

This test is completed in two ways, first with a spring dynamometer and a 500g steel block, and then with a paper cup filled with water on the inclined floor surface.

The surface of the solid wood floor evaluated in these two times is relatively smooth, and the values measured by the spring dynamometer are also relatively low. We put a 500g steel block on the floor surface, and the test shows that it needs at least 3N force to pull the steel block. The strength of 3N is really small for a healthy person. Therefore, our preliminary conclusion is that the slip resistance of this Myanmar teak is poor.

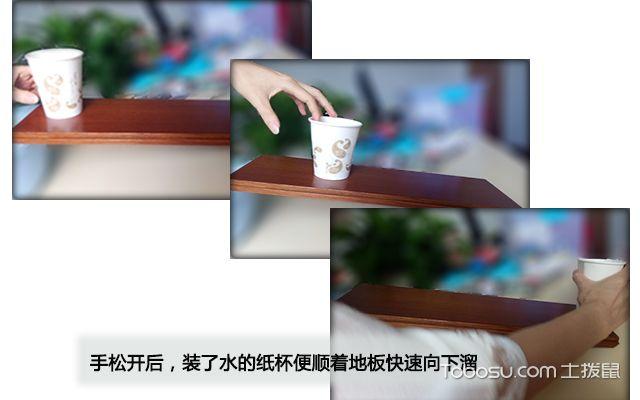

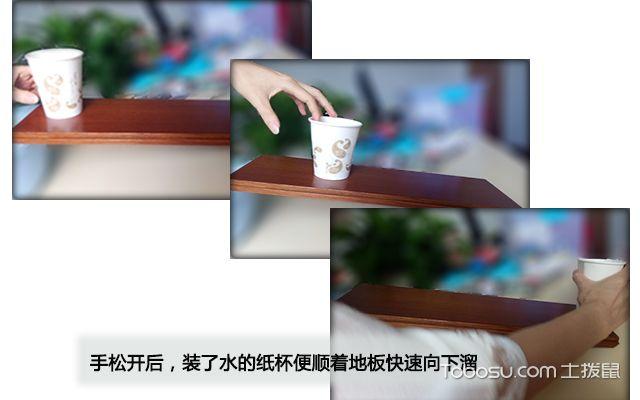

Place a paper cup filled with more than half of the cup of water on the floor surface placed at an angle (to prevent the friction between the bottom of the paper cup and the floor from being increased due to water, we have wiped the water at the bottom with a dry cloth), and observe the state of the paper cup on the floor after releasing the hand. As soon as I released my hand, the paper cup slipped down quickly and the tester caught it in time. If there is some resistance on the floor surface, the paper cup cannot slide so fast.

How about the skid resistance of this Myanmar teak solid wood floor? We can already give the answer, that is, "the skid resistance is not enough and needs to be improved". If there are old people, children, or pregnant women in the home, the use of this floor may be in danger of slipping.

3.3 Abrasion resistance test

Similarly, in addition to using steel blocks and sandpaper to test the abrasion resistance of the floor, we will also use the key to cooperate with the test.

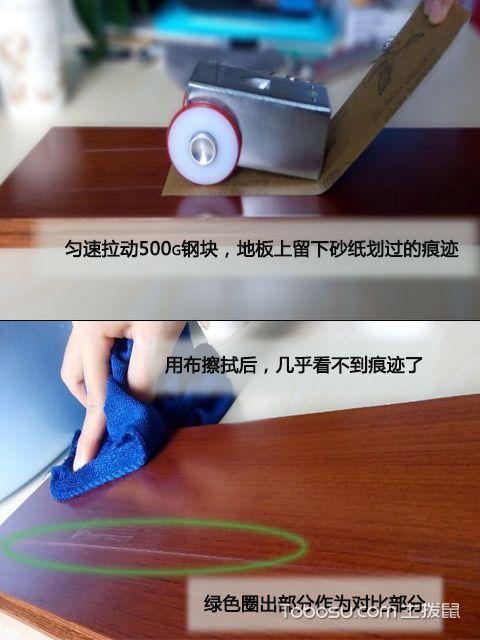

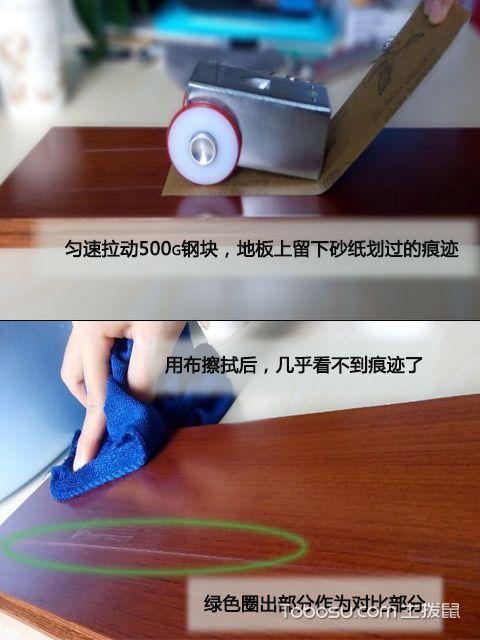

There is a 500g steel block on the 600 mesh sandpaper. Pull one end of the sandpaper with hands at a constant speed to observe the abrasion marks left by the sandpaper on the floor. Why use 600 mesh sandpaper and 500g steel block? Because the larger the mesh size, the more delicate the sandpaper is. The 600 mesh size is exquisite enough for home use; The 500g steel block represents the weight of the object in general. After sliding, there is obviously abrasion mark of sandpaper, but after wiping with cloth, the mark is almost invisible.

Then, we use the key to test the abrasion resistance of the floor surface.

The key scratched hard on the floor surface, trying to leave traces. In order to make the observation more clear, we wiped the dust off the surface, but even in the bright place, there was almost no scratch on the key. In a word, the wearability of this Myanmar teak solid wood floor is OK. If it is very full, you can get at least 8 points. Usually, high heels are rubbed on the floor twice more, and the owner does not have to worry about damaging its beauty.

3.4 Surface hardness test

Under the pressure of 1000g, the 6H pencil left a very clear black scratch on the floor surface. After wiping with a cloth, you can still see the traces one by one. At one end of the floor, as shown in the figure above, we have wiped the graphite layer with cloth for many times, but we still cannot wipe it off. It seems that it has been firmly embedded in the wood.

In order to continue to test the hardness of the floor, the tester stood on the inclined floor in person, and no deformation of the floor was found by naked eye observation. In general, the surface hardness of the floor is not enough to resist scratching of hard objects, but the overall hardness of the floor is very good.

3.5 Impact resistance test

The ball fell from a height of 1m to the floor surface, as shown in the figure, and very clear craters can be seen. Similar to the evaluation results of the round bean solid wood floor, the impact resistance of the floor is not enough. Although there is no phenomenon of being broken or cracked, it is still smashed out of a small hole. For the floor with poor impact resistance, we must try to avoid heavy objects falling on the floor, otherwise we will be distressed if we are hit.

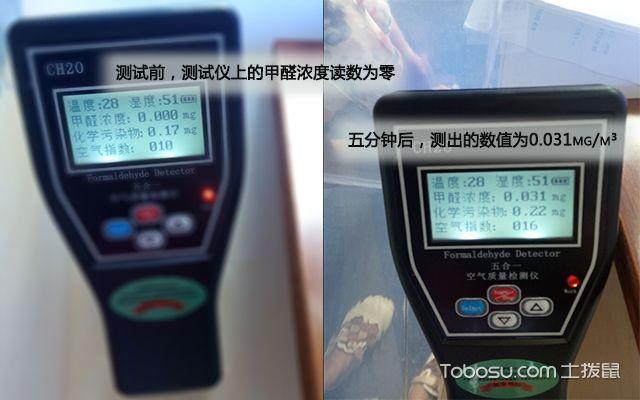

3.6 Environmental protection test

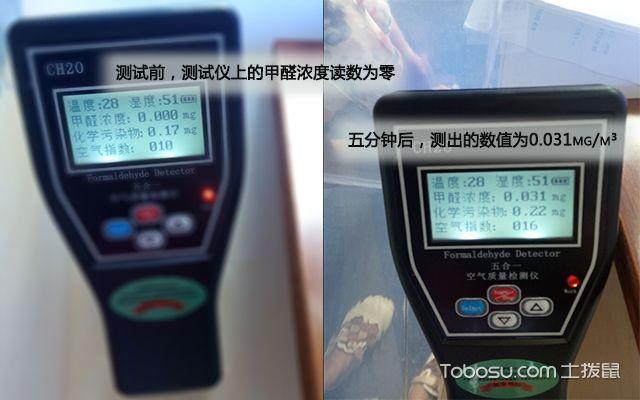

The environmental protection of solid wood flooring has always been the focus of owners. For this solid wood floor, we need to check whether formaldehyde meets the standard. According to the test rules, we read the measured values 5 minutes after the test. The Hygienic Standard for Formaldehyde in Indoor Air in China is 0.08mg/m3, and the data measured this time is 0.031mg/m3, which is completely lower than the standard value. We have reason to say that the environmental protection of this solid wood floor is trustworthy!

3.7 Soaking test

Immerse one end of the floor vertically in 5cm deep water, and observe the changes of the floor after standing for 24 hours. The next day when we observed the test results, we saw a very gratifying scene: the water soaked in the floor is still clear. We still clearly remember that when testing the water resistance of the round bean solid wood floor, the water in the basin was slightly red... When observing the surface of this floor, there was no swelling problem, but through naked eye observation, the side lines were still straight. This is just a comment based on feeling, which is not enough evidence. We used vernier caliper again to measure the thickness, and the data obtained was 18.12mm, which was the same as the data before the test! It can be seen that this is a solid wood floor with excellent water resistance!

Part 4 Summary

Rainy weather is frequent in the south, so you can use this floor, so you can not be afraid of the humid and changeable climate. But it should also be reminded that families with children, the elderly and pregnant women should be careful to use them to prevent falls.

After carefully evaluating this solid wood floor, I always feel a little regret in my heart. This Myanmar teak solid wood floor of Dawson Ginger has excellent environmental protection. The owners can use it with confidence. It also has strong stain resistance. The product process is also good. Even if it is soaked in water for 24 hours, it will not have deformation problems. However, the high temperature resistance is not enough. In terms of skid resistance, surface hardness, and impact resistance, the performance is just normal. If other performance manufacturers can also work hard, this floor is a conscience floor and worthy of users' favor.

Myanmar teak solid wood flooring manufacturer evaluated in this paragraph: Shenzhen Dasen Jinge Wood Industry Co., Ltd

Address: Floor 1, Building 28, Wangjingkeng Industrial Zone, Dahan Village, Xili Town, Shenzhen

This article was first published on Groundhog Decoration Website (www.tobosu. com). Please indicate the original address for reproduction: http://www.tobosu.com/article/xcjy/1341.html

Explanation of related terms in this article

-

floor

Pinyin: floor d ì b ǎ n

-

Wood floor

According to the Forecast and Analysis Report on the Production and Marketing Demand and Investment of China's Wood Floor Manufacturing Industry from 2013 to 2017, the sales volume of Chinese floor manufacturers in 2010 was about 399 million m2, up 9.6% year on year. The sales volume of laminate flooring is about 238 million m2, up 12.3% year on year; Solid wood floor is about 43 million m2, with a year-on-year growth of 2.4%; Solid wood composite floor is about 89 million m2, up 7.2% year on year; Bamboo flooring is about 25.3 million m2, with a year-on-year increase of 1.2%; Other floors are about 3.2 million m2, up 45% year on year. At present, laminate flooring occupies a large market share of nearly 60% in the domestic wood flooring market. Although the production and sales volume of domestic wood flooring has increased significantly in recent years compared with previous years, affected by a series of factors such as China's population and wood flooring prices, the per capita wood flooring area in China is still at a lower level than that in western developed countries. According to statistics, in 2010, the per capita area of laminate flooring and solid wood flooring in Europe alone reached 0.79 square meters, while that in China was only 0.03 square meters, a huge gap. This also reflects the huge potential demand of China's wood flooring market from the side. In addition, stimulated by a series of national policies, such as the construction plan of affordable housing and the introduction of building materials to the countryside, the domestic market demand for wood flooring will surge in the coming years. The huge market share has attracted the attention of many businesses. At present, there are more than 5000 wood floor manufacturers of different scales in China, most of which are small-scale enterprises with extensive production. Among them, there are some illegal vendors who ignore the industry norms, disrupt the industry price, confuse the floor product level, and the plagiarism is prevalent. The malicious competition among businesses has become the soft rib of the industry development. With the introduction of the new regulations, the brand concentration of flooring enterprises will accelerate, a large number of inferior enterprises will be eliminated, and domestic wood flooring enterprises will quickly usher in a reshuffle. Later, the number of domestic flooring brands will be controlled at about 100, of which the top ten flooring brands will occupy 60% of the market share.

-

teak

Carmine teak is a tropical tree species, which requires high temperature. Vertical distribution is mostly found in low mountains, hills and plains below 700-800 meters above sea level. Teak is a light loving tree species. The annual average temperature in the country of origin is 20 ℃ - 27 ℃, the low temperature is 2 ℃, and the annual rainfall is 1100-3800 mm. It is obvious in dry and wet seasons. Strong positive tree species can grow on red soil and lateritic red soil developed from sand shale and granite, and like deep, moist, fertile and well drained soil. It can be planted in places free from low temperature and frost (- 1 ℃ - 2 ℃), shallow roots, large crowns, wind damage and shelter. Teak grows fast and has strong germination ability, and can be regenerated after cutting. The tree can reach 50 meters in height and 2.5 meters in diameter at breast height. The trunk is straight. Branchlets are quadrangular. Single leaf, opposite to each other, large, obovate, broadly elliptic or round. The flowers are arranged in a large panicle, terminal or axillary, the calyx is bell shaped, 5-6 short lobed, and the fruit is enlarged, ovoid or pot shaped; Fruit globose, densely covered with rust colored hairs, hidden in the persistent membranous calyx. Teak wood properties being loaded: Teak wood is glossy, preferably from Myanmar. Teak wood is oily and bright, with uniform color and straight texture. The crude fiber in the teak structure is medium in weight and has a very small drying shrinkage coefficient. The drying shrinkage rate is 2.2% in the radial direction and 4.0% in the tangential direction from raw wood to air drying, which is one of the smaller deformation coefficients in wood. It has good bending resistance, extreme wear resistance, and air drying density of 0.65g/cm3 (dry wood weight is about 650kg/m3). No warping or cracking under the condition of great changes in dry and wet conditions in the sun and rain; Strong water resistance and fire resistance; It is resistant to termites and sea insects in different sea areas, and extremely resistant to decay. It has good drying performance, good adhesive, paint and waxing performance. It is difficult to cut when machining because it contains silicon and is easy to blunt. With good nail holding force and good comprehensive performance, it is recognized as a valuable tree species in the world. Verbenaceae is distributed in some Southeast Asian countries, such as Myanmar, Indonesia, Laos, Vietnam, Thailand, and India. There are also some in China near the border of Yunnan, among which Thailand and Myanmar are more famous. This species is mainly imported from Myanmar. Form: Teak is a tall tropical broad-leaved tree, up to 39-45 meters high, with a diameter at breast height of about 1.5 meters. The bark is brown or gray, and the branches are quadrangular and stellate hairy. Leaves opposite, extremely large, ovate or elliptic, densely covered with grayish yellow stellate hairs on the back. The panicle is broad, and flowers are white and fragrant in autumn. World's precious timber tree species; Rub teak leaves into pieces with your hands, and your fingers are stained with blood red dye, which is difficult to clean for a while, so it is called carmine tree or blood tree. Suitable growth temperature: higher temperature of 43-48 ℃ and lower temperature of 2 ℃.