Yaxin Great Wall Barrier Coating What is the spraying sequence of interior wall coating construction

1、 Difference between interior wall coating and exterior wall coating

2、 What is the spraying sequence of interior wall coating construction

1. Base treatment

2. Preparation before painting

3. Construction process of emulsion paint (emulsion paint) - spray bucket spraying

3、 Related concepts

1. Weatherability

2. Paint

3. Aging

Extended Reading

-

How to identify the quality of anticorrosive coating at the completion stage? How to identify the quality of anticorrosive coating at the completion stage? After the decoration is completed, we can still identify the quality of the paint from the painted wall surface, mainly from the three aspects of drying time, scrub resistance and weather resistance, which are introduced below. How to identify the drying time of anti-corrosion coating quality. According to the national regulations, the surface drying (surface drying) time of coatings should be less than 2 hours, and some high-end coatings of big brands can be less than 1 hour. If the humidity and temperature reach certain suitable conditions, the surface drying time can also be shortened, and some can even be dried within half an hour, which is the characteristic of high-quality coatings. Scrub resistance. The judgment of scrub resistance is very simple. After painting, there are usually many processes to be done, such as installing wooden doors, floors, wardrobes, lamp hardware, sofa furniture, etc. Workers are liable to dirty the wall if they are careless. At this time, if they can wipe it off, it is basically qualified scrub resistance paint, otherwise it is suspected of false publicity. Weather resistance. When the paint is used, it needs to withstand the test of climate, such as the comprehensive damage caused by light, cold and hot, wind and rain, bacteria, etc. Its resistance is called weatherability. Due to the influence of temperature, humidity, bacteria and other factors, the coating with poor weather resistance will gradually change from shiny to dirty and dark over time, and may be accompanied by slight powder shedding, which is also the performance of poor coating quality. The quality of paint directly affects the quality of wall decoration, so the quality of paint must be paid attention to. The above mentioned methods to identify the quality of coatings can provide reference for everyone, and I hope they can be helpful. label: Anticorrosive coating -

How to quickly and accurately identify the quality of anti-corrosion coatings? How to quickly and accurately identify the quality of anti-corrosion coatings? Wall decoration is a very important link, which directly determines the style and final effect of the overall home decoration to a certain extent. Choosing a high-quality paint can help us avoid many unnecessary troubles. How to quickly and accurately identify the quality of anti-corrosion coatings? How to distinguish the quality of anti-corrosion coating In the process of home decoration, there are two situations for the purchase of coating: the owner buys it by himself or the construction party packs the materials. For the latter, we can only screen its quality during construction or after decoration. If the owner buys the goods himself, he must be careful. He should not only listen carefully to the salesperson's introduction, but also observe the following details. Look at the brand. Many home decoration professionals on the Internet often say not to pay too much attention to the brand of paint. In fact, it means to pay more attention to the essence of some paint on the basis of well-known brands. It does not mean that you can buy three no products without looking at the brand. What are the well-known paint brands on the market now? You can check them online before buying. We won't list them here (to avoid the suspicion of advertising). Remember to do some simple homework before buying. Look at the package. The so-called "packaging is the face of an enterprise", a powerful formal enterprise, because of the large sales volume of its products, its packaging printing volume is also large (less printing volume will lead to increased costs), so the packaging will look very delicate and formal. Look at the price. Regular brand coatings are produced according to the formula, and the price will not be too cheap; However, the coating with poor quality, some of which are jerry built, and some are even produced in small workshops, has low cost and is much cheaper than the regular coating. If there is a big difference between the paint price and the market price, it is better not to take advantage of small gains, otherwise it is easy to suffer big losses. label: Anticorrosive coating -

How to identify the quality of anti-corrosion coatings in 2020? How to identify the quality of anti-corrosion coating? Anticorrosive coatings play an important role in paint coatings, which is an indispensable part of paint coatings. How to identify the quality of anti-corrosion coatings in 2020? How to identify the quality of anti-corrosion coating? 1. Detection of film adhesion Paint adhesion refers to the ability of the paint film to combine with the surface of the object to be coated or between coatings. General test standards for film adhesion include: GB/T1720-1979 Determination of Film Adhesion GB/T9286-1998 Cross cut Test of Paints and Varnishes Film GB/T5210-2006 Pull off Test of Paints and Varnishes Adhesion 2. Detection of film thickness The thick film standard of general anti-corrosion materials is about 100 μ m or 150 μ m. Heavy anti-corrosive coating shall be more than 300 μ m or more. Within the scope of this standard, its anti-corrosion effect is the best. Therefore, it is very important to detect the rear modulus. The test standards include: GB/T13452.2-2008 Determination of Paint and Varnish Film Thickness 3. Fineness test, that is, the fineness of solid matter in the paint. Fineness has great influence on film quality, film gloss, durability and storage stability of coatings. However, the finer the better, too small will affect the adhesion of the paint film. Test standards include: GB/T1724-1979 Determination of Coating Fineness GB/T6753.1-2007 Determination of Grinding Fineness of Paints, Varnishes and Printing Inks. Viscosity is used to indicate the viscosity of paint. Test standards include: GB/T2794-2013 Determination of adhesive viscosity Single cylinder rotary viscometer method GB/T9269-2009 Determination of paint viscosity Stommer viscometer method GB/T1723-1993 Determination of paint viscosity GB/T6753.4-1998 Determination of flow time of paints and varnishes with flow cup 5. Detection of nonvolatile content The nonvolatile content is also called solid content, Its content has a great relationship with the film quality and the use value of the paint. The test standards for nonvolatile content include: GB/T1725-2007 Determination of nonvolatile content of paints, varnishes and plastics label: Anticorrosive coating -

What are the requirements for anti-corrosion coating construction? What are the requirements for anti-corrosion coating construction? Anticorrosive coating has a high anti rust effect of hot galvanizing, no need for primer, steel surface treatment, saving man hours, low cost, and effectively shortening the construction period. What are the requirements for anti-corrosion coating construction? Anticorrosive coating construction requirements 1. For work at heights, people are positioned at the height of the benchmark. When working in a building, if the operation is carried out on a shelf of more than 2m, it is called work at heights. In the coating work, the proportion of high falling and object strike accidents in high place work is the largest. Properly wearing helmets, safety belts or erecting safety nets as required can effectively avoid casualties. 2. In terms of electrical hazards, electrical hazards to painting operations not only cause fire and explosion, but also involve other safety issues. Electrical hazards include static electricity, lightning and electric shock. Static electricity can cause electric shock to the human body, resulting in combustion, explosion and other hazards. Lightning mainly refers to the damage to electrical equipment and control system and personal injury caused by lightning stroke. Electric shock accidents happen suddenly in the past, causing serious consequences in a very short time, endangering human life safety. 3. Chemical pollution and toxic injury: solvent coating products themselves have certain chemical hazards. In the work of Xuzhuang, it should be noted that the solvent and diluent in the paint may cause air pollution and harm human health. 4. Fire and explosion hazard solvent based coatings, as well as diluents used in painting operations, are mostly flammable and explosive materials, so the painting operation itself has hidden dangers of fire and explosion. The possible causes of fire and explosion are that electrostatic coating does not comply with the operating procedures, which is easy to generate spark; Waste paint, paint mist, waste rags of paint materials and solvents, etc. are not well kept, and they are easy to cause spontaneous combustion and ignition when stacked together; Improper selection or use of electrical equipment, or failure to timely repair after damage, insufficient explosion-proof grade, etc; Lightning disaster in thunderstorm season. 5. In terms of noise hazard, sound exceeding 100dB is strong noise. People working under this noise will temporarily reduce their hearing, but can recover it. However, hearing loss or even hearing loss caused by noise above 150dB cannot be recovered. Therefore, if it exceeds 85dB, protective measures must be taken. The noise level will vary according to the equipment type, location and location. Excessive noise needs to protect workers' hearing. label: Anticorrosive coating -

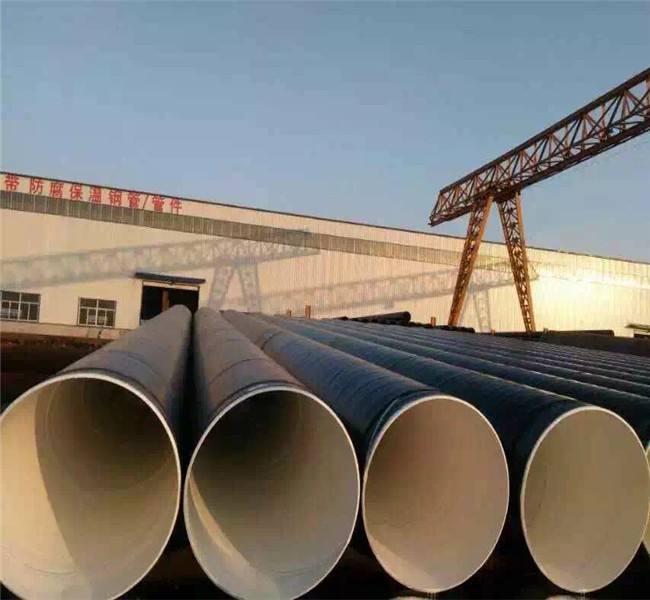

In which fields will anticorrosive coatings be generally applied? Anticorrosive coating refers to a class of liquid or solid materials that can form a film on the surface of an object under certain conditions to protect, decorate or perform other special functions (insulation, rust prevention, mold prevention, heat resistance, etc.). What fields will anticorrosive coating be generally used in? Anticorrosive coating application field ① emerging marine engineering: offshore facilities, coastal and bay structures, offshore oil drilling platforms; ② Modern transportation: highway guardrails, bridges, boats, containers, trains and railway facilities, automobiles, airport facilities; ③ Energy industry: hydraulic equipment, water tanks, gas tanks, oil refining equipment, oil storage equipment (oil pipes, oil tanks), power transmission and transformation equipment, nuclear power, coal mines; ④ Large industrial enterprises: paper making equipment, pharmaceutical equipment, food and chemical equipment, internal and external walls of metal containers, pipelines, storage tanks, mine smelting, cement plant equipment, floors, walls and cement components with corrosive media in chemical industry, steel, petrochemical plants; ⑤ Municipal facilities: gas pipeline and its facilities (such as gas holder), natural gas pipeline, drinking water facilities, garbage treatment equipment, etc; label: Anticorrosive coating -

What are the characteristics of anti-corrosion coatings? What are the characteristics of anti-corrosion coatings? Anticorrosive coatings are used to prevent corrosion of metals and protect the service life of non-ferrous metals under general conditions. Many of them are not very clear about anti-corrosion coatings. What are the characteristics of anti-corrosion coatings? The characteristics of anti-corrosive coating can be used under harsh conditions and has a long anti-corrosion life. Heavy anti-corrosive coating can be used for 10 years or more in chemical atmosphere and marine environment, and can be used for more than 5 years even in acid, alkali, salt and solvent media and under certain temperature conditions. Thick film is an important symbol of heavy anti-corrosive coatings. The dry film thickness of general anti-corrosive coatings is about 100 μ m or 150 μ m, while the dry film thickness of heavy anti-corrosive coatings is more than 200 μ m or 300 μ m, and 500 μ m~1000 μ m. The corrosion resistance of ZS-711 coating was evaluated according to the U.S. NACE standard [PR-01-76 (1983) revised version ItenNo.53105, and the results showed that the coating successfully passed the 4000h salt spray test and 4000h damp heat test. The coating has weather resistance, aging resistance, radiation resistance, wear resistance, impact resistance, high temperature resistance (400 ℃~600 ℃), low temperature (- 60 ℃), and stable conductivity; Its resistivity can meet the anti-static requirements and ensure the long life of the coating. Strong adhesion The coating has strong adhesion to the substrate. The coating composition contains hydroxyl (- OH). The metal matrix provides positive ions, which can form chemical bond bonding. With the help of coupling agents in the coating, even covalent chain bonding can be achieved. Under the maintenance of the spatial network structure, the metals, metal oxide nanomaterials and rare earth oxide ultrafine powders contained in the coating composition help the coating to form a dense interface transition layer, so that its comprehensive thermodynamic properties match the matrix. It is efficient, convenient and easy to apply. It really realizes the self curing of inorganic coatings at room temperature. When the ambient temperature is 20 ℃ and the relative humidity is less than 85%, the surface drying time is 15min, and the solid drying time is 2h, which can ensure efficient construction, and achieve excellent salt fog resistance and aging resistance. The coating is self repairing. Local scratches caused by external forces can still be protected. The coating is not damaged by cutting and welding. Welding with coating will not affect the welding quality. Flexible method of use Inorganic polymer anticorrosive coating can be used alone or as anticorrosive lower layer coating in combination with organic paint. Single layer inorganic polymer anticorrosive coating can be used with epoxy system, acrylic system and polyurethane system when used as primer. ① Excellent anti-corrosion performance: good adhesion, excellent anti-corrosion performance and long service life. ② Excellent construction performance: it can be cured quickly at room temperature like conventional anti-corrosive coatings, which is easy to operate and can be operated by unskilled people (this is the main reason why chlorinated rubber heavy anti-corrosive coatings can be widely used). ③ Excellent environmental protection performance: the solid content of traditional solvent based anti-corrosive coating can only reach 50~60%, while the solid content of high solid heavy anti-corrosive coating can reach 70%~80%, or even 90%~100%. The solvent is reduced by nearly half, showing good environmental protection performance. label: Anticorrosive coating -

What are the types of conventional anti-corrosion coatings? What are the types of conventional anti-corrosion coatings? Anticorrosive coatings, generally divided into conventional anti-corrosive coatings and heavy anti-corrosive coatings, are an indispensable part of paint coatings. What are the types of conventional anti-corrosion coatings? Types of conventional anti-corrosion coatings: epoxy resin paint: thick film epoxy zinc rich primer, epoxy micaceous iron antirust paint, epoxy glass flake, epoxy coal tar pitch paint, epoxy floor paint. Vinyl chloride paint: primer, finish, machine tool paint, hammer paint, fireproof paint, anti-corrosion paint, varnish, perchloroethylene putty. Chlorinated rubber paint: chlorinated rubber finish of various colors, chlorinated rubber aluminum powder antirust primer, chlorinated rubber antirust primer, chlorinated rubber iron red aluminum powder antirust paint, chlorinated rubber ship bottom antifouling paint. Acrylic paint: acrylic polyurethane finish varnish, various colors of acrylic polyurethane enamel, acrylic road marking paint. Fluorocarbon paint: various colors of fluorocarbon anti-corrosion paint, metal fluorocarbon paint, fluorocarbon exterior wall paint. Alkyd paint: mica iron oxide alkyd antirust paint, alkyd hull paint of various colors, alkyd enamel of various colors. Silicone heat-resistant paint: various silicone self drying paint, various silicone baking paint, silicone heat-resistant insulating paint, aluminum powder heat-resistant paint, muffler heat-resistant paint. Solvent free anti-corrosive paint: solvent free epoxy glass flake heavy anti-corrosive paint, solvent free epoxy coal tar pitch paint, solvent free pipeline inner wall drag reduction paint, solvent free self leveling floor paint. Special anti-corrosion coatings: ethylene phosphating primer, inorganic zinc rich primer, water-based inorganic zinc rich primer, glass paint, template paint. label: Anticorrosive coating -

How to choose art coatings? It's reliable to choose a big brand How to choose art coatings? Art paint is a new type of wall decoration art material, which has become the choice of many friends, but many friends do not know how to choose, so how to choose art paint? It's reliable to choose a big brand! Xinbei Shell Environmental Protection Material Technology Co., Ltd., founded in 2016 with a registered capital of 50 million yuan, is a new high-tech paint enterprise integrating research and development, production, sales, construction and service. It is located in Changchun, one of the four major garden cities in China and known as the "Spring City of the North". 2. Wanxi Qicai Shell New Material Technology Co., Ltd. is mainly engaged in the R&D, production, sales and construction of industrial and civil interior and exterior wall coatings, with a registered capital of 50000000 yuan. The company is headquartered in the Light Industry Industrial Park, Nong'an Economic Development Zone, Changchun City, Jilin Province. The company covers an area of nearly 60000 square meters, with a total construction area of more than 30000 square meters. 3. Jinbei Shell Jilin Jinbei Shell New Material Technology Co., Ltd. is a joint-stock company specializing in the research, development, production and sales of shell powder health coatings. The company is composed of domestic experts engaged in the research and production of shell powder health coatings. It has two production bases in Changchun and Linyi, a research and development center, modern laboratories for purification, humidity regulation, mildew, pore structure, etc., and 76 research and development personnel, including one doctor and seven masters. 4. Jinnanmu Jilin Jinnanmu New Material Technology Co., Ltd. is a large-scale comprehensive private enterprise integrating shell powder research and development, production, sales, construction and service, with a registered capital of 10 million yuan. The company's operation headquarters is located in Changchun, Jilin Province. The operation headquarters is composed of investment promotion department, construction department, customer service department, planning department and other departments. The production base of Jinnanmu shell powder is located in Xianggong Industrial Park, the intersection of Beijing East Road and Industrial Park Road, Linyi City, Shandong Province. The production base has a research and development center, modern laboratories for mildew, pore structure, and various test and detection equipment, and multiple full-automatic production lines to achieve large-scale production. 5. In the minds of most interior designers, ModernClassic=Bauhaus. Bauhaus, which means "BuildingSchool" in German, is a school founded by the famous German architect Walter Gropius in Weimar, Germany, in 1919. Therefore, the famous school that publishes and educates unique design techniques, ushers in a new era of modernism, and gradually becomes a synonym for classic modernism. As a model of modernism, Bauhaus firmly gets rid of the historical constraints, emphasizes the reconciliation of the artificial environment, advocates that architecture and design should develop with the development of the industrial age, pays attention to practical functions and economic issues, actively adopts new materials and new structures of the industrial age, and applies them to the technological innovation of architectural design. label: Artistic coating -

Does art paint have formaldehyde? Is there any physical harm? Does art paint have formaldehyde? Now people have a strong awareness of environmental protection. When they decorate, they are most worried about formaldehyde, which is unsafe, unsanitary, and also volatilizes toxic and harmful gases. Now art coatings are favored by many families. Is there formaldehyde in art coatings? How harmful is it? Does art paint have formaldehyde? At the production stage of artistic coatings, the quality of raw materials has been strictly controlled, and the entire production and processing process has been standardized. No other harmful chemicals have been added in the process, so the materials themselves will not volatilize toxic and harmful gases. In addition, during construction, artistic coatings can be adsorbed on the wall without adding chemical glue, and there will be no formaldehyde generated from chemical glue, Therefore, decoration of the room with artistic paint will not pose any threat to human health and will not cause any harm to the children at home. Generally, you can stay at ease two or three days after decoration. What toxic and harmful gases will be left after the house is decorated, and what are their respective hazards? After decoration, the common harmful gases in the room are formaldehyde, benzene, ammonia, etc. Among them, formaldehyde has a very bad effect on human respiratory tract, eyes, liver and lungs; Benzene is recognized as a carcinogen, which can cause poisoning symptoms and damage human nervous system and hematopoietic system; Excessive ammonia inhalation will lead to emphysema and bronchospasm. When decorating, people pay special attention to whether the formaldehyde content exceeds the standard. After the room is decorated, there will be formaldehyde more or less, but it is hard to smell. Even if it exceeds the indoor formaldehyde content standard, it may not be impossible to smell it. If we smell formaldehyde indoors, the formaldehyde content will seriously exceed the standard. Which materials will produce toxic and harmful gases? Many materials for interior decoration will volatilize the above gases. Some inferior materials have the above gases themselves, and some materials are of good quality. However, during the construction process, glue is required for bonding, and the glue will volatilize harmful gases such as formaldehyde. Is there any way to prevent or eliminate these toxic and harmful gases? Ventilation naturally emits, and harmful gases in the purified air can also be chemically removed. A special air purification team is invited to remove formaldehyde and other gases through professional means. Of course, the best thing is to check the product quality from the source. Before decoration, choose low formaldehyde or formaldehyde free materials to control formaldehyde below the standard line. label: Artistic coating -

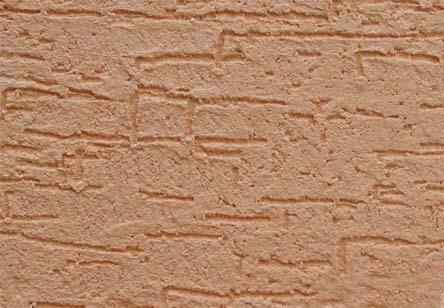

What are the advantages and disadvantages of artistic coatings? What are the advantages and disadvantages of artistic coatings? With the improvement of the material level of the public and the gradual pursuit of spiritual taste, artistic coatings and artistic wall materials came into being. To accept a new product, it is necessary to first understand the article. What are the advantages and disadvantages of artistic coatings? The first advantage of artistic coatings is ecological and environmental protection: for consumption, health is the first element. Most of the raw materials of artistic coatings and artistic wall materials are made of inorganic materials, without adding chemical agents, so there will be no toxic substances, which will naturally protect the ecological environment. Therefore, only with ecological and environmental protection can we pursue a higher artistic level. 2、 Mold proof and moisture-proof: some high-quality art paint art wall materials also have the characteristics of mold proof and moisture-proof. Because the material itself has the characteristics of breathing and breathability, the moisture inside the wall can be released through the wall materials, thus eliminating problems such as bulges, peeling, cracking, etc. Especially in the rainy season, the wall will absorb the moisture in the air, When the air is dry, the water vapor will be released to regulate the humidity. 3、 Strong plasticity: there are more than 100 colors of artistic wall materials of artistic coatings, which can not only achieve the smooth stone effect like jade, but also create the rough and thick ancient castle effect. Compared with traditional wallpapers, the pattern effect of artistic coating and artistic wall materials is more lifelike. In addition to the exquisite decorative effect, it has completely replaced wallpaper. The disadvantage of artistic coatings is that due to the characteristics of art itself, the construction is much more difficult. There is a saying in the industry that "three parts of materials, seven parts of work." So if you want to choose artistic wall materials of artistic coatings, you must have a professional construction team to carry out the construction. Another point is that the repair of artistic coatings and wall materials is poor. Because of the integrity of the art itself, if the art coating art wall material is damaged by careless bumping and scraping, it will be troublesome to repair and will damage the integrity of the original design. There will be a visual sense of not being the whole. label: Artistic coating

Paint agent joining

-

10 minutes ago Mr. Zhao from Zhejiang Province has consulted on joining -

18 minutes ago Mr. Zhou of Henan obtained the joining materials -

38 minutes ago Mr. Wang of Guangdong has consulted on joining -

56 minutes ago Ms. Xie from Guangdong Province consulted on joining -

58 minutes ago Mr. Yu of Zhejiang obtained the joining materials -

1 hour ago Mr. Ni from Jiangsu Province consulted on joining -

1 hour ago Mr. Du from Zhejiang Province has consulted on joining -

1 hour ago Mr. Huang from Guangdong Province consulted on joining

Submitted successfully

-

Hot News -

Selected information

-

Exterior wall paint color effect picture Exterior wall color panorama picture appreciation -

Is there anything fishy about the 19800 yuan Oupai? Is the European Pie 19800 Package a Trap? -

It is not recommended to decorate the house with wall cloth? What's the reason? -

Opaicn and European school are not the same. The difference between Opaicn and European school -

When is the bamboo wood fiber integrated wall fraud? Learn more to avoid being cheated

-

How to open an integrated wall franchise store -

How much is 304 anti-theft window? Why buy 304 anti-theft window -

The post-90s warm men spent only 50000 yuan to transform 200 ㎡ dilapidated old houses into super sunshine houses- Sun room -

Wall elastic materials What are wall materials -

I really regret putting up wallpaper

Ten related brands

-

Top 10 brands of doors and windows -

Top ten brands of aluminum alloy doors and windows -

Top 10 brands of customized home -

Top 10 brands of plate -

Top 10 paint and coating brands -

Top ten brands of waterproof materials -

Top 10 brands of smart lock -

Top 10 brands of kitchen appliances -

Top 10 brands of integrated stoves -

Top 10 brands of clothes hanger -

Top 10 brands of integrated ceiling -

Top 10 integrated wall brands -

Ten major brands of diatom mud -

Top 10 ceramic brands -

Top 10 bathroom brands