684 core MODF optical distribution frame 684 core MODF Optical distribution frame (Ningbo Pinyue Communication Manufacturing) [China Telecom] [China Mobile] [China Broadcasting]

Time flies, two thousand and sixteen The year has passed quickly. In this year, communication equipment 684 core MODF optical fiber distribution frame Great changes have taken place, and the industry competition has become increasingly fierce. Some manufacturers think that two thousand and sixteen Year is a communication equipment 684 core MODF optical fiber distribution frame In the first year of technology development, we tried to open a new era with innovative technology. Some manufacturers are on the verge of collapse and have lost in the wave of innovation, leaving many complaints. In my opinion, Communication equipment 684 core MODF optical fiber distribution frame It is under this cruel competition that the industry can continue to develop and progress. although two thousand and sixteen Years have passed away from us, but still left us a lot of products and events worth reviewing. So we made a special inventory two thousand and sixteen Let's have a look at the high-quality and affordable products of the communication product industry in.

684 core MODF optical fiber distribution frame| OMDF optical distribution frame | MODF optical distribution frame | OMDF optical distribution frame | Communication industry standard of the People's Republic of China Optical Distribution Frame YD/T 778-2006 Optical Distribution Frame Q/CT 2354-2011 Technical Requirements for China Telecom Optical Distribution Frame FTTH access layer optical fiber distribution frame | optical fiber jumper frame specification (288 core, 576 core, 648 core, 720 core, 792 core, 864 core, 960 core, 1152 core, 1440 core optical fiber main distribution frame) rame, OMDF for short). The functions of OMDF are diversified.

[Ningbo Pinyue Communication Equipment Co., Ltd.] Pinyue connects the world! Information communicates the mind!

Telephone:*** Fax: *** mobile phone: *** - ***

Q Q : 474665107 – 225357557 WeChat:***

684 core MODF optical fiber distribution frame off key Words

MODF optical fiber distribution frame; Standards; Classification structure; Construction scheme

one

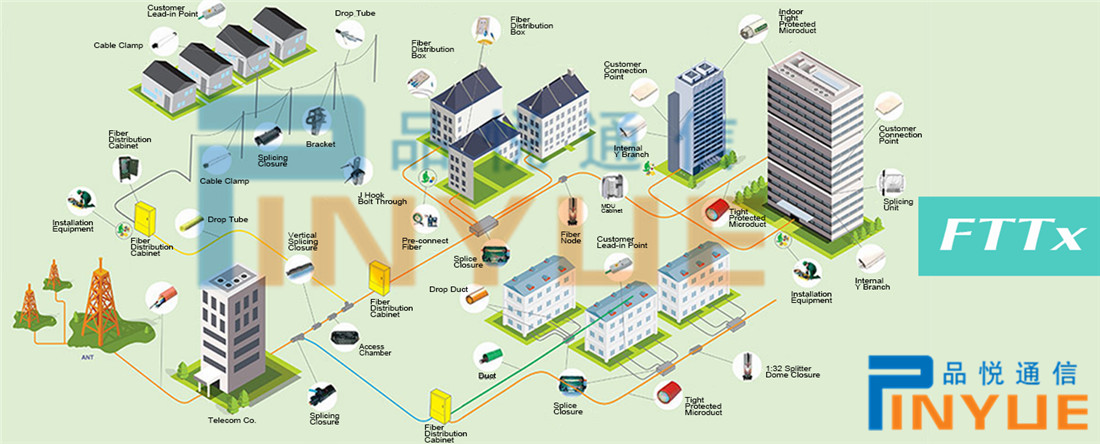

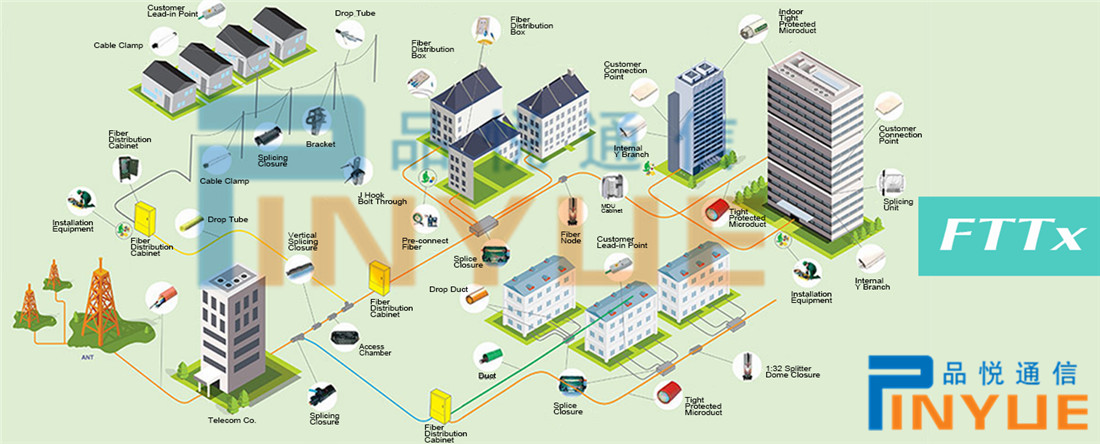

Construction Background In recent years, with the rapid progress of optical fiber in copper, optical fiber to the building, and optical fiber to the home, access network construction has ushered in the era of FTTx based optical fiber access. A large number of access optical cables converge to different computer rooms such as OLT, transmission, and data. The number of optical cable terminals in the computer room continues to increase, and the number of optical fiber hops is also increasing, The demand for optical hop management and flexible scheduling has also been further improved, but due to the limitations of the traditional ODF frame's own hop management capability and scalability, the following problems are mainly caused:

one point one

Chaotic management The existing incoming optical cables are distributed in various professional computer rooms, and all are equipped with ODF optical distribution frames. Most businesses require more than two professional computer rooms to achieve fiber hopping. The amount of optical cables between computer rooms is large, and the routing and fiber hopping are chaotic, which makes it impossible to achieve unified management and is not convenient for adjustment and maintenance.

one point two

The traditional "small and complete" layout structure of ODF shelf with unclear boundaries blurs the interface of construction and maintenance, which is easy to become the repeated winding of jumping fibers, which is not conducive to flexible scheduling and is not suitable for the construction of larger capacity.

one point three

The access layer optical cable and the trunk layer optical cable are terminated in the same ODF frame, and the frequent construction and maintenance of the access layer optical cable can not guarantee the safety of the trunk layer optical cable, so there are hidden dangers. With the further promotion of the access network optical fiber strategy, the above problems will become increasingly serious. For this reason, the installation of optical fiber distribution frame (MODF) should be considered in the planning and construction of the computer room in the future to gather a large number of access optical cables, and gradually solve the maintenance, management, security and other problems.

two

Introduction to MODF and establishment of relevant standards

Main Optical fiber Distribution f rame, Referred to as MODF, hereinafter referred to as MODF) applies all the use and maintenance methods of MDF, with in-line and horizontal end modules. The in-line side is connected to the external optical cable, and the horizontal side is connected to the optical communication equipment. The communication route can be distributed and connected through the fiber hopping. It has horizontal, vertical, front and back fiber paths, which is convenient for the maintenance, management and expansion of high-capacity fiber hopping, and can be installed with link test ports.

At present, MODF has no national or industrial standards, mainly referring to YD/T 778-2006 Optical Distribution Frame, Q/CT 2354-2011 Technical Requirements for China Telecom Optical Distribution Frame, and the enterprise standards of domestic and foreign optical distribution frame manufacturers.

3. Applicable scope of MODF

MODF is applicable to the access layer central office (OLT office) and similar central computer rooms for centralized termination, connection scheduling, monitoring and measurement of access equipment optical cables and external MAN backbone optical cables. It is also applicable to large and medium-sized transmission computer rooms, but access layer MODF and trunk layer MODF should be set respectively.

four

MODF classification and structure

MODF is mainly divided into integrated fusion and fusion

Equipped with two categories of separation type (frame height is divided into 2600mm, 2200mm and 2000mm)

four point one

Integrated fusion and matching

MODF fusion and distribution integrated MODF: It is composed of the distribution frame on the line side connecting the external optical cable and the distribution frame on the line side connecting the optical communication equipment. The in-line side and the horizontal side can be integrated racks or separate racks. The rack is mainly composed of the top seat, base, framework door (If necessary), optical cable fixed stripping unit, grounding, in-line module, jumper receiving unit, horizontal module, horizontal wiring duct and accessories. The following are introduced separately according to the integrated rack and the separated rack:

four point one

. 1 Integrated rack The in-line rack and the horizontal rack of the integrated rack are back-to-back, double-sided operation, and the parallel rack structure is relatively fixed

single. The in-line rack is composed of several end plates to form a unit, which uses 12 core fusion integrated tray components.

Horizontal column frame can Mining use twelve core melt match one body turn Tray or seventy-two core jump Fiber frame group piece 。

684 core MODF optical fiber distribution frame summary

The OMDF optical fiber distribution frame of Pinyue Communication is the high-density optical fiber management solution in the industry, which can adapt to the rapid growth and expansion of optical fiber network, and alleviate the accumulation of cross connection lines in the horizontal trunking. It can easily access connectors and manage optical cables, directly improving the reliability and performance advantages of the network. When operators need to expand their networks or configure new services for end users, Pinyue Communications' optical fiber wiring solutions can meet their long-term needs for future development.

Optical fiber main distribution frame: the horizontal side is connected to optical communication equipment, mainly connected to the equipment side, and provides the fixation of jumper fiber (pigtail) at the equipment side. The in-line side is connected to the external optical cable, which is mainly used to provide stripping and fixing for the outdoor optical cable, provide the reinforced core grounding device and provide the equipment that can form the end of the external cable. In line and horizontal lines use jumpers to distribute and connect communication routes.

2. Applicable environment:

This rack is applicable to medium or large computer rooms with centralized optical fiber management. Can be used for solutions with a large number of fibers.

3. Product Features

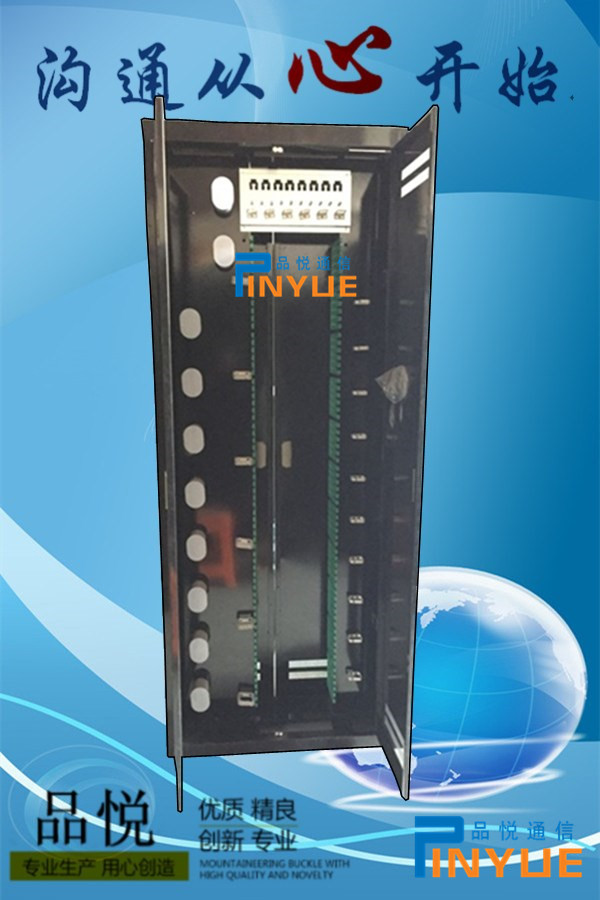

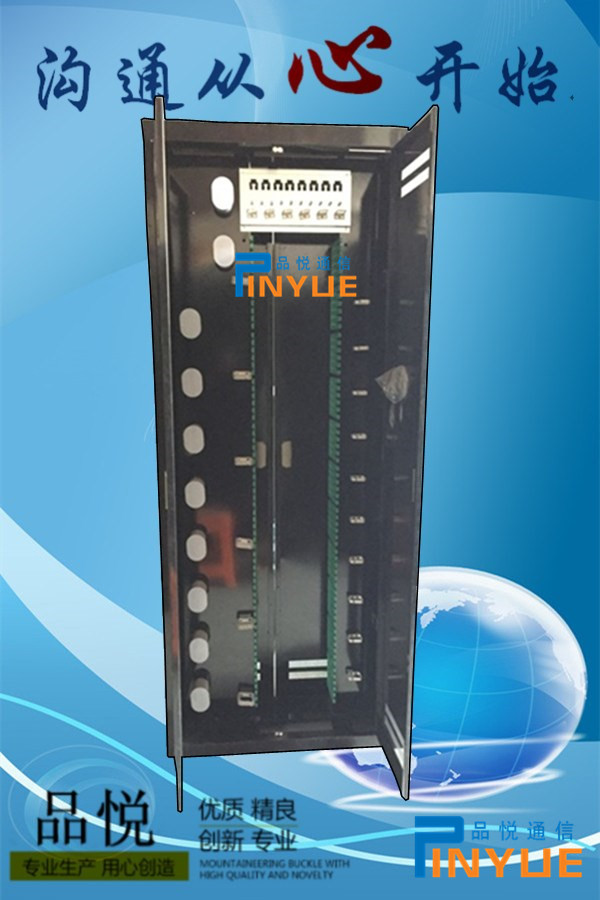

1. The cabinet is assembled as a whole. The top of the cabinet can be connected with the wiring channel of the machine room. The cabinet mainly considers the upper cable entry, while taking into account the lower cable entry.

2. The front side of the rack is the jumper layout area, and the back side is the optical cable layout area. From the front side of the cabinet, there is a column on the left and right inside the cabinet, and its mounting hole is used for installation Adapter Panels and racks can be installed according to the number of panels configured by the user. Each panel can be fixed with 96 cores. Each panel is equipped with a wiring slot below it, which is fixed on the front of the rack (jumper side) to accommodate the fiber hopping channel. The back of the fixed rack (optical cable side) is fixed with a cable rack to accommodate the channel of the optical fiber sheathed after the optical cable is stripped in the bureau.

3. The front side of the device is responsible for the path management of fiber hops and the storage of redundant fibers; The back is responsible for fixing the optical cable in the office, and the back is equipped with optical cable fixing clips. Full front operation. Strong operability, easy installation, parallel support, and full routing protection: various bending radius protection devices distributed at the turning of the routing path ensure the full protection of the optical fiber. The specially designed optical fiber cable stripping protection device ensures the reliability of the fixation, stripping, and grounding of the optical cable. It is applicable to ribbon optical cables and bundle optical cables, and can be used for both upper and lower incoming cables.

I. Construction Background

In recent years, with the rapid progress of optical fiber into copper and back, optical fiber to the building, and optical fiber to the home, the access network construction has ushered in the era of FTTx based optical fiber access. A large number of access optical cables converge to different computer rooms such as OLT, transmission, and data. The number of optical cable terminals in the computer room is increasing, and the number of optical fiber hops is also increasing, The demand for optical hop management and flexible scheduling has also been further improved, but due to the limitations of the traditional ODF frame's own hop management capability and scalability, the following problems are mainly caused:

1. Management confusion

The existing incoming optical cables are distributed in various professional computer rooms, and all are equipped with ODF optical distribution frames. Most businesses require more than two professional computer rooms to achieve fiber hopping. The amount of optical cables between computer rooms is large, and the routing and fiber hopping are chaotic, which cannot achieve unified management and is not convenient for scheduling and maintenance.

2. The boundary is not clear

The traditional "small and complete" layout structure of ODF frame blurs the interface of construction and maintenance, which is easy to cause repeated winding of fiber hopping, which is not conducive to flexible scheduling and is not suitable for construction of larger capacity.

3. Unclear hierarchy

The access layer optical cable and the trunk layer optical cable are terminated in the same ODF frame. The frequent construction and maintenance of the access layer optical cable cannot guarantee the safety of the trunk layer optical cable, and there are hidden dangers.

With the further promotion of the optical fiber strategy of access network, the above problems will become increasingly serious. For this reason, the installation of optical fiber distribution frame (OMDF) should be considered in the planning and construction of the computer room in the future to gather a large number of access optical cables and gradually solve the problems of maintenance, management and security.

2、 Introduction to MODF and establishment of relevant standards

Optical Fiber Main Distribution f rame, Referred to as MODF, hereinafter referred to as OMDF) applies all the use and maintenance methods of MDF, with in-line and horizontal end modules. The in-line side is connected to the external optical cable, and the horizontal side is connected to the optical communication equipment. The communication route can be distributed and connected through the fiber hopping. It has horizontal, vertical, front and back fiber paths, which is convenient for the maintenance, management and expansion of high-capacity fiber hopping, and can be installed with link test ports.

At present, there are no national and industrial standards for OMDF, mainly referring to YD/T 778-2006 Optical Distribution Frame, Q/CT 2354-2011 Technical Requirements for China Telecom Optical Distribution Frame, and the enterprise standards of domestic and foreign optical distribution frame manufacturers.

3、 Applicable scope of OMDF

OMDF is applicable to the access layer central office (OLT office) and similar central machine rooms, for the centralized termination, connection scheduling, monitoring and measurement of access equipment optical cables and external MAN backbone optical cables. It is also applicable to large and medium-sized transmission machine rooms, but the access layer MODF and trunk layer MODF should be set respectively. OMDF

4、 OMDF Classification and Structure

The OMDF is mainly divided into two categories: integrated fusion and separation fusion (frame height is 2600mm, 2200mm and 2000mm).

1. Melting and matching integrated OMDF melting and matching integrated MODF: It consists of the distribution frame on the line side connecting the external optical cable and the line side connecting the optical communication equipment. The in-line side and the horizontal side can be integrated racks or separate racks.

The rack is mainly composed of the rack top base, base, framework, door (when required), optical cable fixing stripping unit, grounding, in-line module, jump fiber receiving unit, horizontal module, horizontal wiring channel and accessories.

The following are introduced separately according to the integrated rack and the separated rack:

2. Integrated rack

The in-line rack and horizontal rack of the integrated rack are back-to-back structure, double side operation, and the parallel rack structure is relatively fixed and single. The in-line rack is composed of several end plates to form a unit, which uses 12 core fusion integrated tray components. The horizontal rack can adopt 12 core fusion integrated tray or 72 core fiber hopping frame components.

2. Split rack

The separated rack is composed of the optical fiber melt fiber terminal frame and the equipment side distribution frame, which are two separate optical fiber distribution frames. The combination is flexible, and can realize full front parallel frame structure or back-to-back parallel frame structure. The in-line rack is composed of several end panels to form a unit, which uses 12 core fusion integrated tray components. The horizontal rack can use 72 core fiber hopping frame or 12 core fusion integrated tray components. Two side parallel rack scheme of separate rack (combination of two front and back to back parallel racks),

3. The combination of fiber optic MDF of separate rack is flexible, and in practical application, multiple full front or back-to-back fiber hopping fields can be formed according to the capacity of the machine room.

4. Fusion separation type

Melting and separating OMDF: It is composed of fiber melting frame and fiber distribution frame, which are used together.

Fused fiber rack is a rack that leads all optical cables into the ground and concentrates the connection function with pigtail in the same subrack. The rack is composed of fixing, stripping, bundling, grounding, etc. of optical cables, and the two sides are the welding area of the welding plate.

Melting and separating OMDF fiber rack

The fiber distribution rack is a rack that centralizes all end forming functions in the same subrack and realizes the optical transmission routing and scheduling function. The rack is composed of an external line end forming area, an internal line end forming area, a tail cable fixing area, and a fiber hopping area. Each area is independent of each other. The external line and the internal line adopt the reversible fiber hopping unit frame. The combination scheme of fusion and separation OMDF is mainly based on single side operation,

The above is the combination and combination scheme of OMDF produced by mainstream manufacturers at present. The division of labor between the external line side and the equipment side interface of the double-sided rack is relatively clear, but double-sided operation is required; The full front frame can be installed back-to-back or against the wall, which is easy to operate. In engineering applications, appropriate rack and parallel rack schemes can be selected according to the specific application scenarios, management modes, operation habits, and capacity requirements on the outside line side and equipment side to build a high-capacity fiber hop field with good capacity expansion, clear fiber hop management, and flexible use.

5、 OMDF application

OMDF installation scenario

OMDF should be installed as close to OLT or Other equipment Machine room, and consider outgoing The Conduit The routing, capacity and other factors of physical channels such as shafts and channels in the building can be divided into settings on the same floor (or in the same machine room) and settings on different floors. The specific settings can be selected according to the following priority:

1. When the space conditions of the existing cable distribution room are met, the cable measurement room is preferred to set OMDF;

2. When the space conditions of the existing cable distribution room are not satisfied, the OMDF equipment should be in the same machine room as the OLT equipment as far as possible;

3. If the existing OLT or transmission room space conditions are not met, separate OMDF rooms can be set on the same floor or different floors.

6、 Requirements of OMDF installation on computer room

The OMDF machine room should try to choose a machine room with sufficient length to make the OMDF be placed in a row as far as possible to form a fiber hop field. If it is placed in two columns, the fiber jumpers between columns can only go through the cable rack on the top of the machine room, which is not conducive to maintenance.

When OMDF and other equipment are set in the same machine room, the area of the machine room should be based on the final capacity of the machine room, and the demand space and reserved space for OMDF, OLT, dedicated line access equipment, power supply and other equipment should be comprehensively considered; When setting different machine rooms, only the space required by OMDF and the reserved space need to be considered, and at the same time, the installation position reservation of online test equipment should be considered. OMDF

1. Suggestions on connection between OMDF and equipment

When connecting OMDF and equipment, it is recommended to select the tail cable. According to different use scenarios, dual head or single head (welded on the OMDF equipment side) pigtail can be selected

Note: When the cable is set in the same machine room or on the same floor, the length of the tail cable between the OMDF and the equipment is well controlled, and it is recommended to use double end tail fiber connection or tail fiber connection; When different layers are set, it is difficult to measure the tail cable length between the OMDF and the equipment. The OMDF head and tail cable or the indoor optical cable with single head and tail fiber customized by the manufacturer shall be used for connection. The 12 core fusion integrated tray shall be selected at the equipment side of the OMDF rack. OMDF

7、 Conclusion

With the promotion and use of OMDF, it will gradually solve the problems of chaotic management, difficult expansion, and difficult maintenance of optical cables in the current agricultural production system room. However, the introduction of each new product requires a certain running in period, which urges us to continue to study in depth how to combine the evolution with the existing network and long-term deployment scheme to meet a large number of business needs of future users.

2.2 Product specifications

Configuration table of optical distribution frame:

|

Overall dimension (mm)

H × W × D

|

Outside line side

|

Equipment side

|

Total capacity

|

Adapter

|

|

wiring

unit

(72 cores)

|

Tray

number

(pcs)

|

more

Number of cores

(Core)

|

wiring

unit

(72 cores)

|

more

Number of cores

|

|

2000 × 550 × 550 (bare frame)

2000 × 6000 × 600 (side plate and door)

|

nine

|

fifty-four

|

six hundred and forty-eight

|

six

|

four hundred and thirty-two

|

one thousand and eighty

|

FC/SC

|

|

2200 × 550 × 550 (bare frame)

2200 × 600 × 600 (side plate and door)

|

ten

|

sixty

|

seven hundred and twenty

|

seven

|

five hundred and four

|

one thousand two hundred and twenty-four

|

|

2600 × 550 × 550 (bare rack)

2600 × 600 × 600 (side plate and door)

|

twelve

|

seventy-two

|

eight hundred and sixty-four

|

eight

|

five hundred and seventy-six

|

one thousand four hundred and forty

|

3、 Use of 72 core function module

72 core integrated frame

It is made of high-quality cold-rolled steel plate, and the door plate can be overturned and disassembled. Each door plate has 72 cores. It is equipped with two pairs of six position guide plates and six 12 core integrated trays

3.2 Adapter base plate/tray

◎ Adapter base plate

It is suitable for the installation of SC or FC type optical fiber adapters. It can flexibly access SC or FC jumper/pigtail. In order to facilitate future maintenance and management and reduce wiring workload, it is recommended to take the local network as the unit, and only one connector is selected for each unit.

◎ Integrated tray for fusion

The 12 core fusion integrated tray is designed with left and right fiber output adjustable to meet the functions of external cable fusion, tail fiber storage, fiber hopping terminal, etc. Tray fusion plate.

4、 Installation

The rack and 72 core terminal fusion module are delivered as a whole. The bottom of the rack is fastened to the ground with four M10 * 80 expansion screws supplied with the machine. The top is provided with four ф 9 holes for connecting the cable rack (slot) in the machine room. When installed side by side, the adjacent side plates can be removed to facilitate the jumper between racks.

Use and maintenance

Rack structure

(1) The frame is of open structure, and the frame body is integrally welded with cold-rolled steel plates. The left and right side plates (external hanging) and front and rear door plates can also be installed as required. Each door is fixed up and down with a magnetic suction. The door of the rack adopts a movable hinge, which can be flexibly disassembled. The opening angle of the door is not less than 110 °, and it can be opened and closed freely for 2000 times without damage.

(2) The rack adopts double-sided operation, and the front side is the line side in-line module. The right fiber outlet mode is used for the fixation, stripping, welding and termination of external cables; On the back is the device side horizontal module, which adopts the left fiber out mode for the fixation and termination of the device cable. On the right side of the rack is a fiber winding wheel for storing fiber hops, which is common to the line and device side modules.

(3) The rack is suitable for upper and lower cable entry environments. In the upper cabling environment, optical fibers and cables enter the rack from the top and have separate cable (fiber) entry holes; The fiber inlet hole of optical cable (fiber) is protected by fiber guard strip, and has sufficient fiber area.

(4) The horizontal module area on the equipment side of the rack is installed with multi-layer horizontal wiring ducts to meet the fiber routing when multiple racks are combined.

(5) The frame body has a complete protective grounding system. And ensure the effective grounding of the optical cable reinforcing core and its armor layer.

Routing mode

? Outdoor optical cable incoming:

The outdoor optical cable adopts the centralized cable feeding mode. The outdoor cable introduced from the left side of the rack top is peeled, fixed and grounded on the optical cable fixing plate and the intermediate optical cable fixing plate. After that, the protective sleeve is sleeved and led into the integrated tray (front) of each layer along the jumper ring of the left column to be fused with the pigtail for termination (see the fiber routing diagram for details).

? Cable entry of equipment optical cable

The equipment optical cable is led in from the middle of the top. Before reaching the tray on each layer, it is peeled and fixed on the optical cable fastener, and fused with the pigtail in the integrated tray (back) to form an end (see the fiber routing diagram for details).

? Jumping fiber:

When the service needs to be opened, connect the front and rear trays with a jumper fiber. Jump fiber can be fixed in length, and the jump fiber can not leave the wiring

Grounding device

The high-voltage protective grounding device of the rack is connected with the metal reinforcing core and metal sheath in the optical cable, and the sectional area of the connecting line is greater than 6 mm two 。

6、 Packaging, transportation and storage

1. Packaging

The rack packaging box shall comply with the requirements of GB3873-83 for wooden box packaging, with moisture-proof and shockproof measures. There are packing list, spare accessories, certificate of conformity, instruction manual and other technical documents in the box, and the whole machine is sealed with plastic bags. There are shockproof and moisture-proof materials in the box, and signs such as rainproof, moisture-proof, stacking and anti quantity and direction are painted outside the box.

2. Transportation

The rack can adapt to the transportation of various means of transportation. During the transportation of packaged products, the ambient temperature is required to be - 30 ℃~55 ℃, the relative humidity ≤ 90% (at 30 ℃), and there should be a canopy to avoid direct rain and sun exposure; Loading, unloading and handling shall be carried out according to the transportation operation marks painted on the packing box.

3. Storage

The number of stacked boxes of packaged distribution frames shall not exceed the number of stacked boxes printed on the packaging box. The product shall be stored in a well ventilated and dry warehouse, without corrosive gas around it, and the storage temperature shall be - 25 ℃~55 ℃.

What is optical fiber communication

Optical fiber communication is a kind of communication means which uses light wave as carrier and optical fiber as transmission medium to transmit signals from one place to another.

Advantages of optical cable communication

Compared with the previous electrical communication, optical fiber communication has many advantages: its transmission frequency bandwidth and communication capacity are large; Low transmission loss and long relay distance; Fine wire diameter, light weight, raw material is quartz, which saves metal materials and is conducive to rational use of resources; Strong insulation and anti electromagnetic interference performance; It also has the advantages of strong corrosion resistance, strong radiation resistance, good flexibility, no electric spark, small leakage, strong confidentiality, and can be used in special environments.

3 Application and development of optical fiber communication in power system

The power system communication network is a large-scale and well-developed special communication network specially used in China. With the acceleration of the trend of optical fiber communication network, the process of transition from trunk line to access network to optical fiber has been basically completed in many areas of China's power special use communication network. At present, the services carried by the power system optical fiber communication mainly include voice, data, broadband services, IP and other conventional telecommunications services; The professional business of electric power production includes protection, automatic safety devices and broadband data required by electricity marketization. In particular, the protection and safety automatic devices put forward higher requirements for the reliability and safety of optical cables. It can be said that optical fiber communication has become an indispensable part of the safe and stable operation of the power system and the production and life of the power system (public number: transmission and distribution lines).

At the beginning, the application of optical fiber communication in electric power communication was to lay ordinary optical fiber cables by the traditional buried, pipeline, overhead and other methods of the telecommunications department to form the electric power optical fiber communication system. With the progress of technology, in the 1970s and 1980s, some optoelectronic composite optical cables, which are different from traditional optical cables and are attached to power lines and power towers, were developed. These optical cables are collectively referred to as power special optical cables. One of the major differences between power system optical fiber communication and other optical fiber communication systems is the particularity of communication optical cables. The possibility of power special optical cable being damaged by external force is small, and its reliability is high. Although its cost is relatively high, its construction cost is low. After years of development, the manufacturing and engineering design of power special optical cables have become mature, especially the OPGW and ADSS technologies, which have begun to be widely used in domestic power special optical cables, such as the long-distance backbone OPGW optical cable lines in the Three Gorges Project. Relying on the power system's own line resources, special optical cables avoid conflicts and disputes with the outside world in terms of frequency resources, routing coordination, electromagnetic compatibility, etc., and have great initiative and flexibility.

The power system has a powerful power network, which is distributed in cities and rural areas all over the country. It is completely feasible to build an optical fiber communication network with the help of power lines and towers. It can also provide a broadband channel for the development of power grid automation and new relay protection. At present, the urban and rural power network transformation of the power system has also brought good opportunities for the development of power communication. Many provincial, prefecture (city) and county power bureaus have built optical fiber lines to make full preparations for the realization of broadband integrated services digital network (B-ISDN).

The so-called goal is the real goal, which must be kept in mind all the time, thinking about it all the time and dreaming about it all the time! People with goals are running, people without goals are just wandering; Those with goals are grateful for the reality, while those without goals complain about the reality; People with goals often cannot sleep, and people without goals can never sleep! Pinyue Technology Since its establishment, it has insisted on deepening changes, strengthening enterprise management, and adopting new technologies to develop new products. At present, the company has gathered a group of high-quality technical and management talents, equipped with advanced R&D, production and testing equipment, and implemented in all aspects ISO9001 Quality management system ISO14001 Environmental management system certification. [Pinyue Technology Professional production, hard work, communication equipment related people around you]

With strong technical strength and perfect service, Pinyue Technology “ Innovative and pragmatic ” Of enterprise energy to “ Seeking innovation, change and speed ” To welcome the bright future of optical communication.

Partners: China Telecom, China Mobile, China Unicom, China Radio and Television, etc ……

[Ningbo Pinyue Communication after-sales service]

The following is the service commitment of Ningbo Pinyue Communication Equipment Co., Ltd. to customers , It is also our company's basic requirements for after-sales service

To better serve the needs of users , Provide guidance and timely after-sales service , We are based on “ Pursue high quality , superior quality , Customer satisfaction is the purpose ” Energy. with “ Considerate service , Reliable product quality ” Make the following commitments to users in principle:

one , Product quality commitment:

1, The manufacturing and testing of the products meet the national standards.

2, The product is tested by professional testers , Ensure that the product indicators meet your requirements.

3, If there is any quality problem with our products within the warranty period , We are willing to assume all responsibilities.

two , Delivery commitment:

We ensure that the products provided will be delivered to the place of * * * within the time required by the demander , If you have special requirements , To be completed in advance , We can negotiate with you , Ensure that your needs are met in a timely manner.

three , If the goods provided by the supplier are unpacked , Any problems found (including appearance damage) , Must be solved in a way acceptable to users : Timely repair, replacement and exchange for new products .

four , Within the warranty period , Same equipment , The same quality problem cannot be used normally after three consecutive repairs , We promise to change the same brand , New equipment of the same model , And implement product quality “ San Bao ” Services. Out of warranty period , Replacement of equipment provided , Only the cost of spare parts is charged for maintenance , No labor technology and service fees .

five , After sales service capability and within the design service life of the equipment , We promise to ensure that the user can replace the parts of ****** , Ensure the normal use of the equipment. The Tenderer shall specify the maintenance charge standard after the warranty period , Location of maintenance spare parts warehouse and manufacturer's maintenance station.

six , Establish a reasonable sales service management system:

1, Pre sales services. Set up a special sales service organization , The company will arrange relevant professionals to be responsible for the correct and timely use of on-site teaching.

2, Services on sale. To prevent unnecessary losses caused by improper use , In the process of product use , The company will send relevant technical personnel to the grass-roots level to provide technical guidance to users. Ensure the correct use of the product , Make users use it safely , don 't worry.

3, After sales service statement: all services provided by the company are free of charge.

seven , Product after-sales plan

1, After acceptance of normal operation of equipment , Our company assigns professional engineers to be responsible for providing your unit with maintenance and operation training without personnel restrictions on the site , The company prepares training every year two Times. The training content includes: knowledge of correct operation and use of equipment; Identify primary faults and necessary recovery methods; Common troubleshooting methods.

2, Regularly send professionals to the Owner to check the operation of equipment. use “ Consultation system ” And “ Reward and punishment system ’ The combination method can completely solve the problems.

Product quality commitment

one , Product quality commitment:

1, The manufacturing and testing of products are provided with quality records and testing data.

2, Test of product performance , We sincerely invite users to visit the whole process of the product , Full performance inspection , After the products are confirmed to be qualified, they can be packed and shipped.

two , Product price commitment:

1, To ensure high reliability and advancement of products , The materials of the system are selected from domestic or all high-quality brand products.

2, Under equal competitive conditions , Our company will not reduce the technical performance of the product , On the basis of changing product parts , We sincerely offer you a more favorable price.

three , Delivery commitment:

1, Product delivery date: try to meet user requirements , If there are special requirements , To be completed in advance , Our company can specially prepare for production , install , Strive to meet user needs.

Ningbo Pinyue Communication provides 684 core MODF optical fiber distribution frame Spot supply, please contact us if necessary.