Cause analysis of water leakage in elevator shaft and construction scheme of waterproof and plugging in elevator shaft

1、 As the waterproof layer is first made for the bottom plate, the side wall concrete wall is poured again, which leads to the fault between the side wall concrete wall of the elevator shaft and the bottom plate. The original waterproof layer does not have the waterproof effect that it should have, so the groundwater will continue to leak into the elevator shaft from the fault.

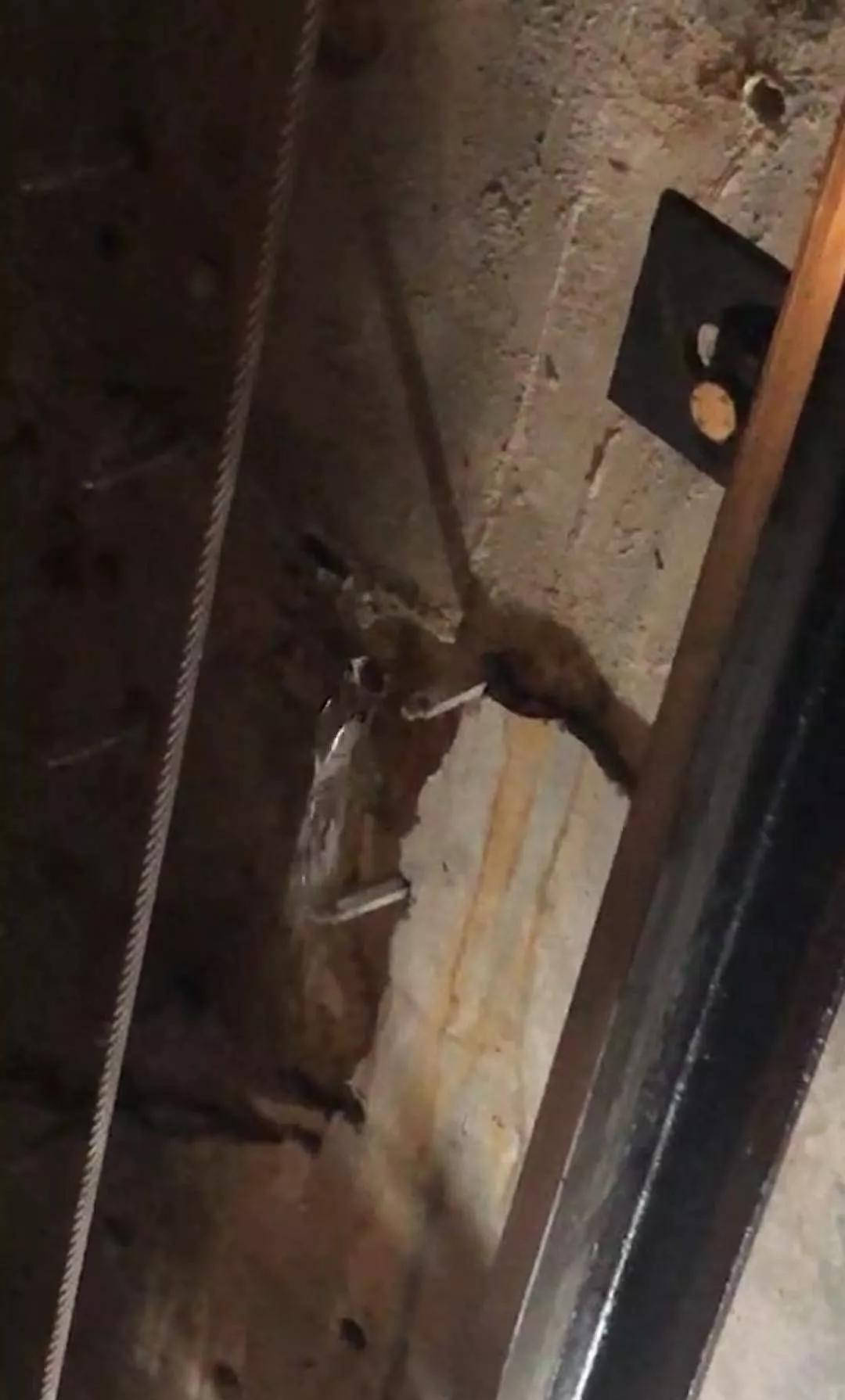

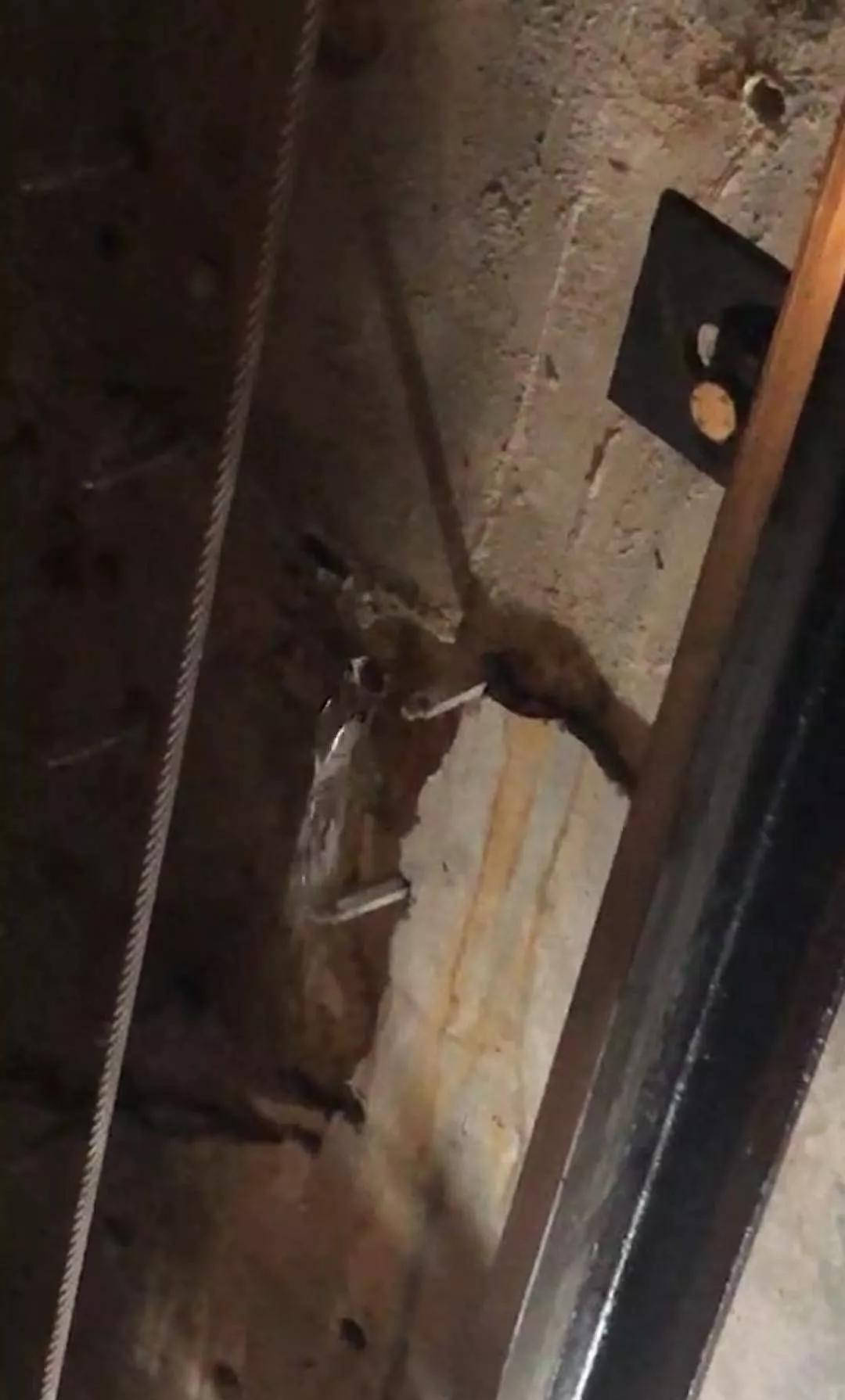

2、 During the waterproof construction of the elevator shaft, a large amount of accumulated water on the bottom plate was not drained, but the concrete was poured directly into the water, resulting in many honeycombs, pockmarks, holes and looseness around the bottom plate. The connection with the bottom plate is not tight, and the bottom of the elevator shaft is generally positive or negative

Below the zero water level, when the underground water pressure is high, the underground water will leak to the pit through holes, pits, cracks and looseness, causing water accumulation in the elevator shaft.

3、 The inside and outside of the side wall of the elevator shaft were not waterproof, which caused groundwater to seep into the wall from the outside wall of the shaft wall, resulting in water accumulation in the elevator shaft.

This is the leakage that the elevator often encounters, which is also often manifested as: honeycomb pitted surface, elevator bottom surface, screw hole floor crack leakage, and internal corner leakage. The following is a detailed analysis of the construction practices of these leakage problems.

Waterproof construction preparation

1、 Machine preparation

Steel wire brush, mixing bucket, electric mixer, press, brush, scraper, broom, ruler, electric drill, hammer, etc., grouting nail of grouting machine.

2、 Material preparation

Rain soluble polyurethane plugging agent, CBDB modified epoxy chemical grouting material, CBDB waterproof sealing paint, CBDB plugging spirit, Yuquan waterproof No.1, Yuquan waterproof No.2, CBDB epoxy mortar.

Water leakage treatment of elevator honeycombed and pitted surface: use electric hammer to chisel the honeycombed and pitted surface to the solid layer, use water to wet the base surface, apply plugging agent, use plugging agent (mixture: powder: water=1:0.25 weight ratio), quickly mix it into mastic, and knead the mastic into pellets. After the mortar starts to heat up, quickly press the mortar into the place. After the water stops, use CBDB waterproof sealing paint and non-woven fabric to strengthen the quality. After that, use CBDB modified epoxy chemical grouting fluid and mortar ratio to trowel, which is what we call epoxy mortar.

Beijing rain full waterproof

Beijing rain full waterproof

Water leakage treatment of the elevator base: if water leakage is found at the elevator base, it cannot be easily chiseled with an electric hammer, otherwise the elevator base will be deformed and the elevator cannot run. Generally, grouting nails can only be embedded around the elevator base. In order to achieve the effect of no water leakage, the drill hole must surround the base to drill holes and embed nails, After the distance between the boreholes is 10-15cm and the height is 10cm, inject CBDB water-soluble polyurethane plugging agent (cyanidation) to press the "CBDB water-soluble polyurethane plugging agent" into the hole with a special grouting machine until it is filled. The grouting method can be carried out one by one from one end to the other end. The grouting pressure of the chemical grout should meet the requirements. The pressure should gradually increase to prevent sudden pressurization. After reaching the specified pressure, the pressure should be stable. After about 10 minutes of water stop, CBDB chemical epoxy grouting fluid should be injected, which will strengthen the two in one, play a reinforcing role, and ensure more reliable quality.

Treatment of elevator screw hole: use an electric hammer to chisel the high level of the screw hole to at least 10cm - 15cm, apply pressure plugging spirit to stop water, then use rain full waterproof CBDB waterproof sealing paint and non-woven fabric to soak it, press it into the hole to achieve good results, and then use leakage plugging and troweling.

Water leakage treatment of elevator floor crack: drill holes along the crack direction at a distance of 3~5cm on both sides of the crack, with the height of about 10cm and the drill hole reaching the crack position. The boreholes shall be drilled along both sides of the crack, and the distance between boreholes shall be 10-15cm; Clean the dust in the borehole, and then install the water stop needle and inject CBDB water soluble polyurethane plugging agent CBDB chemical epoxy grouting fluid with the electric high-pressure grouting machine, which also enhances the quality effect. After grouting, clean the equipment and tools with Tianna water in time.

These are the water leakage problems we often encounter. Generally, elevator shafts cannot avoid these kinds of water leakage problems.

Base course treatment after water stop:

Drain the water at the bottom of the elevator shaft, remove the garbage, elevator oil stain, etc. The elevator oil stain can be removed by using Tianna water to transfer water. The waterproof base surface is required to be qualified to ensure that the base surface is firm, dense, free of open water, oil stain, etc