YD type cemented carbide composite surfacing electrode is referred to as YD type electrode for short:

Introduction to YD type hardfacing electrode:

YD type cemented carbide composite surfacing electrode (YD type electrode for short) is made by mixing granular sintered cemented carbide and elastic matrix alloy. Apply a layer of special flux and color to identify the particle grade size. The sintered cemented carbide particles are mainly cobalt tungsten carbide with hardness of HRA89-91; The matrix metal is "nickel copper" alloy, with tensile strength of 690MPa and hardness of HB ≥ 160.

YD electrode needs to be used together with a backing electrode (YD-D) and flux (YD-R). All are supplied by our factory in proportion.

YD-D backing electrode is a kind of gas welding electrode coated with special flux, and the amount shall be 15% of the weight of YD electrode.

YD hard alloy surfacing electrode

YD-9.5 Oil tool milling shoe, grinding shoe, hydraulic cutter blade.

YD-8 milling shoe, grinding shoe, hydraulic cutter blade, coal planer blade, etc.

YD-6.5 shoe milling, shoe grinding, coal planer cutter, pile driving drill bit, spiral drill bit, road construction machine cutter head, etc.

YD-5 milling shoe, grinding shoe, sleeve milling shoe, coring bit, piling bit, bucket Dipper tooth , key Groove reamer, feeding chute of blast furnace, cutter head of road building machine, etc.

YD-3, YD-10 mesh used for drilling stabilizer, drill pipe wear belt, plowshare, drill pipe Connector , feed grinder hammer, etc

YD-18 mesh is used for drill pipe wear-resistant belt, plastic rubber and leather filing tools, wear-resistant layer surfacing.

YD-30 mesh, used for rubber and leather filing tools, wear-resistant layer surfacing.

YD-R is a flux made of composite, and the amount shall be 2% of the weight of YD electrode.

Usage: YD electrode is mainly used for surfacing some workpieces that are seriously worn or cut in industries such as petroleum, mining, coal mining, geology and construction. Such as: shoe milling, shoe grinding, centralizer, reamer, drill pipe joint, hydraulic cutter, scraper blade, coal planer cutter, coring bit, pile driving bit, spiral bit, etc.

Surfacing process: YD welding rod is used for surfacing with oxygen acetylene flame, and the gas welding nozzle used shall be larger than that used for ordinary gas welding of carbon steel. The flame shall be adjusted to neutral or slightly carbonized flame. The position of the neutral flame core shall be strictly controlled, and the hard alloy particles and the workpiece surface shall not be contacted, so as to avoid over burning, that is, the welding tip shall be higher than that of the ordinary gas welding. This is the key to affect the wear-resistant life of the surfacing layer, and should not be ignored.

The downhand welding position shall be used as far as possible during surfacing, and the appropriate mould shall be used for surfacing at other positions.

The work site must be well ventilated to avoid harm to health.

Specification: YD type welding rod is divided into the following eight grades according to the particle size of cemented carbide:

Brand | Nominal size (mm) | Particle grade size (mm) | colour | remarks |

YD-9.5 | nine point five | 9.5-6.5 | Dark green | |

YD-8 | eight | 8-6.5 | Deep orchid | |

YD-6.5 | six point five | 6.5-5 | red | |

YD-5 | five | 5-3 | yellow | |

YD-3 | three | 3-2 | pink | |

YD-10 mesh | 10 mesh | 10-18 mesh | Light green | |

YD-18 mesh | 18 orders | 18-30 mesh | Light orchid | |

YD-30 mesh | 30 mesh | 30-50 mesh | light yellow | |

Hardfacing technology of YD type hardfacing electrode

The welding rod adopts oxyacetylene surfacing. The operation process is as follows:

(1) Clean the workpiece to make the surface of the weldee show metallic luster.

(2) Take the flat welding position for overlaying welding. For this purpose, use the appropriate mould to control the thickness of the overlaying layer, and use the thickness limiting block.

(3) Preheat with neutral flame. The flame core shall not contact the workpiece surface, and the distance shall be 25mm.

(4) When the workpiece is heated to an appropriate temperature, a layer of flux can be coated on the surface to be overlayed. If the flux is preheated properly, the flux will bubble and boil. At this time, the oxide on the surface of the workpiece will be removed by the flux, and then continue to heat until the solvent is full of the surface to be overlayed and in a transparent liquid state, indicating that the overlaying and backing layer can be started.

(5) For surfacing and backing welding layer, neutral flame shall be used, and the backing electrode shall be used to stir the flux continuously and melt with it. The welding nozzle shall keep running, and its running speed shall be exactly the same as the welding speed of the backing electrode. The flux shall be kept on the surface of the workpiece. At the end of the priming process, a thin layer of smooth priming alloy with a thickness of about 1mm shall be formed on the surfacing surface. If the preheating temperature is insufficient, the molten primer metal cannot be leveled, and the ball or bulge is formed on the surface of the workpiece.

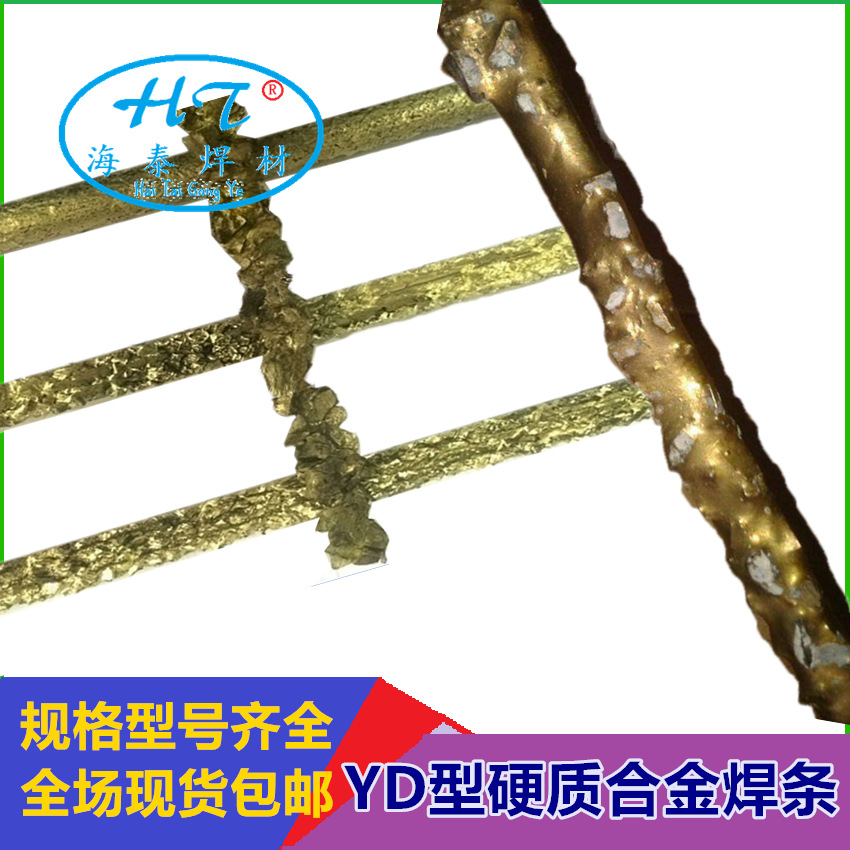

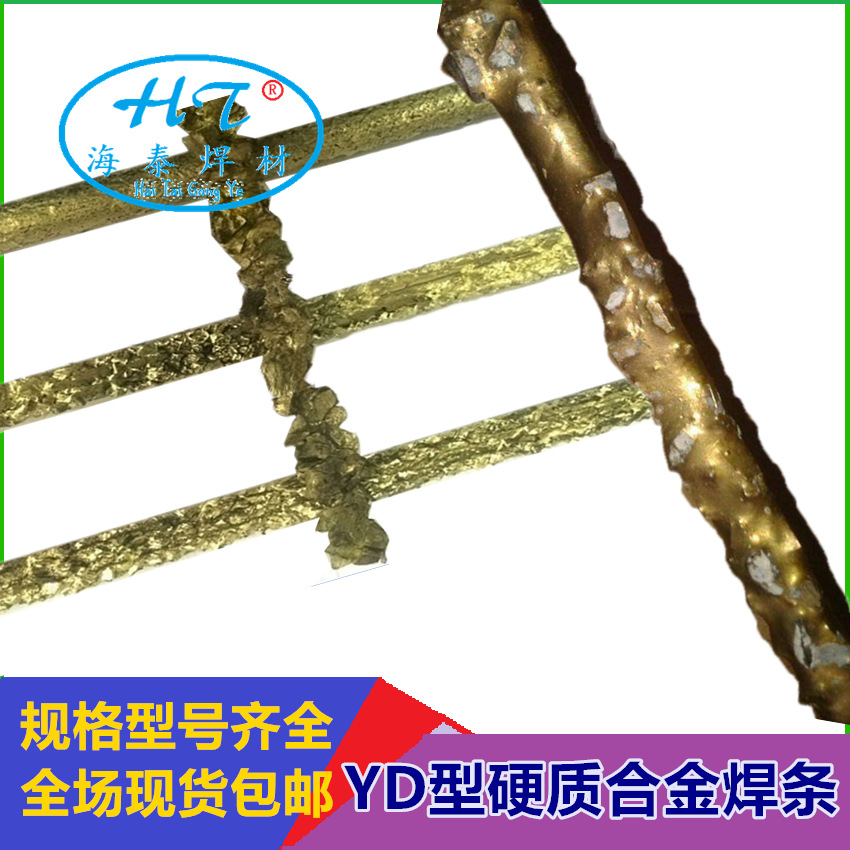

(6) Hardfacing of hard alloy welding layer. On the base alloy layer, use YD type electrode for surfacing, use neutral flame (slightly partial to carbonization flame) welding tip to move evenly and steadily on the surface of the workpiece, and the flame is heated against the alloy electrode (note that the flame core cannot contact the alloy particles), so that the matrix alloy in the electrode melts, and then the carbide particles fall down together. Before the molten matrix metal solidifies, the particles should be arranged. The alloy electrode held in the left hand can be used to pull, or another person holding a backing electrode or graphite rod can be used as a pull rod, and the particles should be quickly pulled aside to make them evenly and orderly arranged. The thickness of surfacing layer shall be controlled according to the design requirements.

(7) After surfacing, the workpiece shall be placed in an unventilated place, cooled slowly, not quenched, and covered with asbestos felt if possible.

(8) After the workpiece is cooled to room temperature, if necessary, the surfacing surface can be ground to the required size and shape.

(9) Clean the workpiece and remove all spatter, slag, etc.

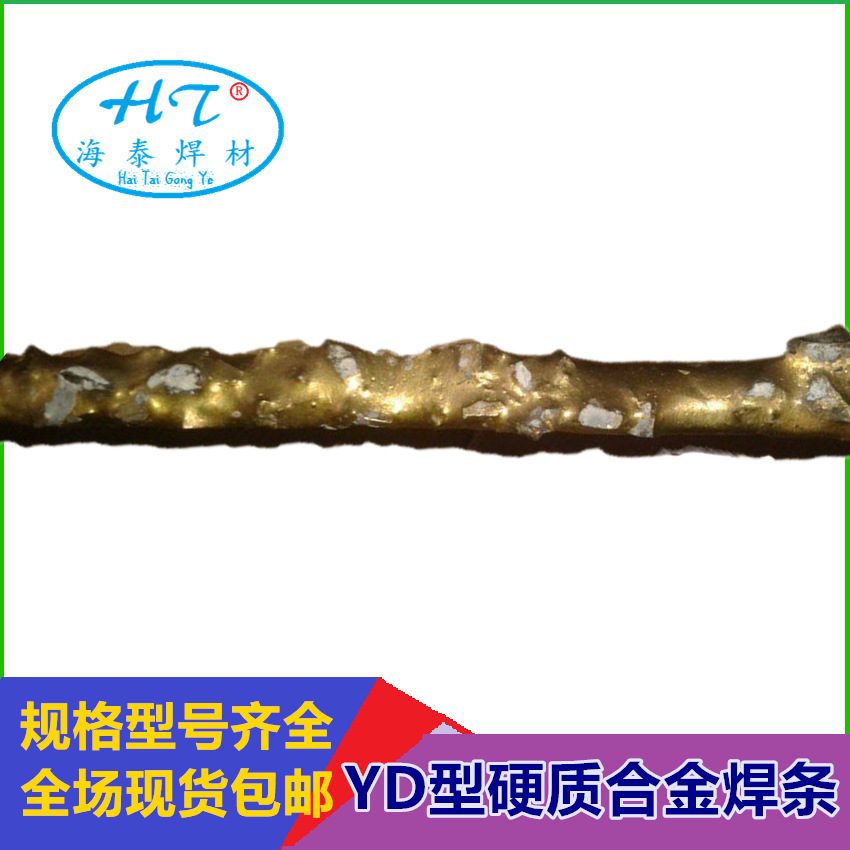

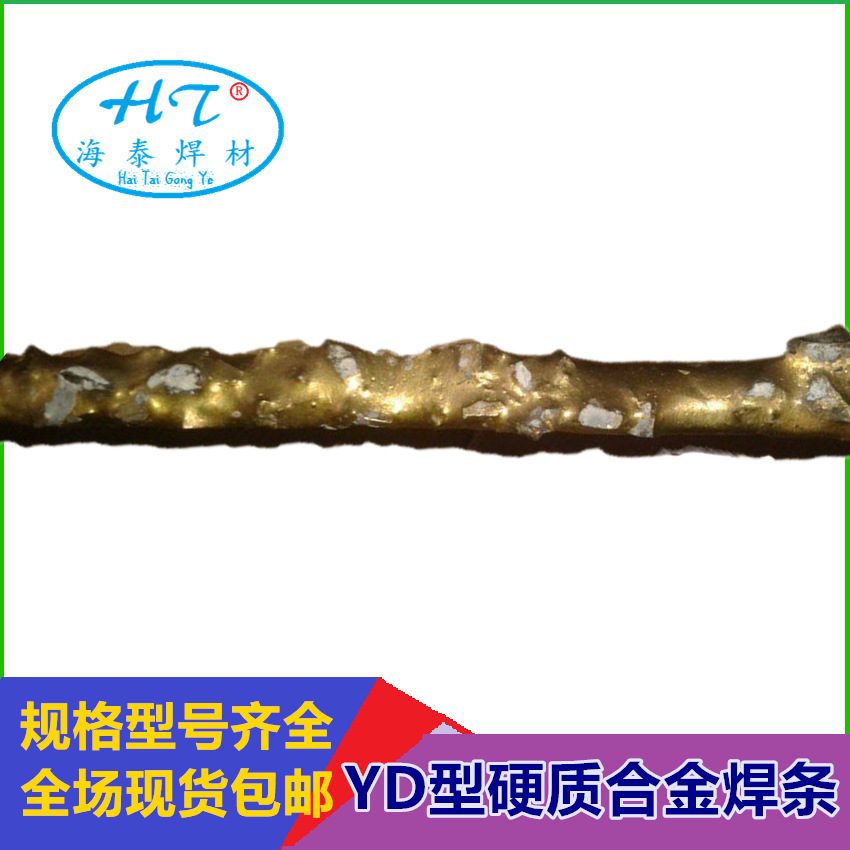

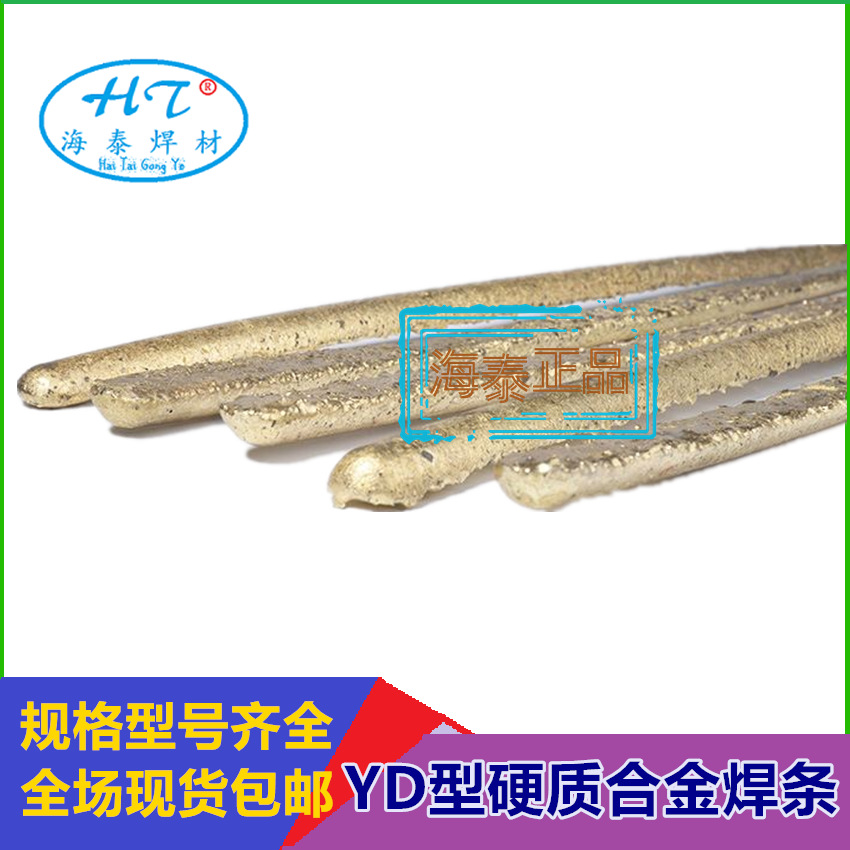

The surfacing operation method is correct, and the sign of satisfactory quality of the surfacing layer is: after cooling, the surface of the surfacing layer shows shiny gold colour The matrix alloy of the surfacing layer is well combined with the base metal, the alloy particles are closely arranged, and are evenly and firmly welded into the matrix metal.

The sign of overheating or overburning is that the metal of the matrix turns red after cooling, and the alloy particles expose the black surface. The consequence is that the working performance of the alloy particles is damaged, affecting the service life.

The sign of insufficient heating is: after cooling, it is dull silver gray, the matrix alloy is poorly bonded with the base metal, and the entire surfacing layer is in danger of falling off when the tools after surfacing are running.