![Jaw crusher @ Fanke Kuaitou [kt. fkw. com]](https://cbu01.alicdn.com/img/ibank/2019/687/761/11293167786_1363350618.jpg)

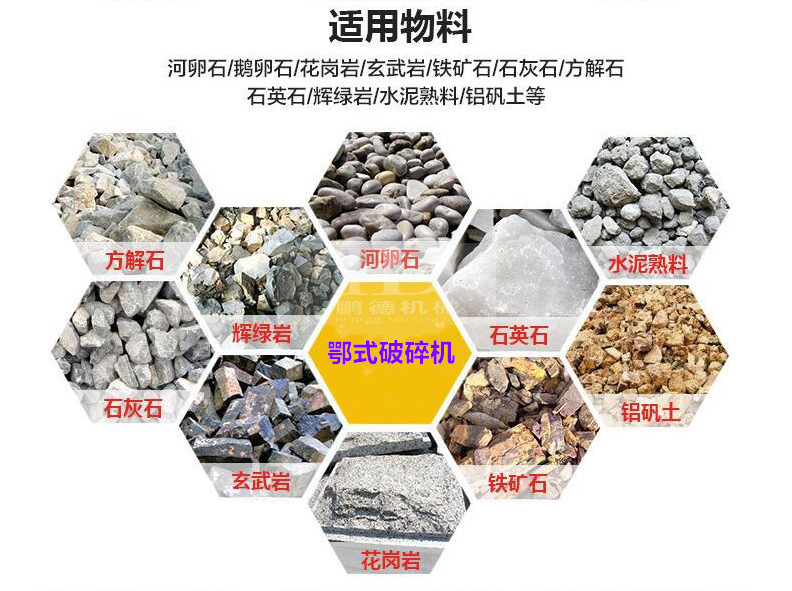

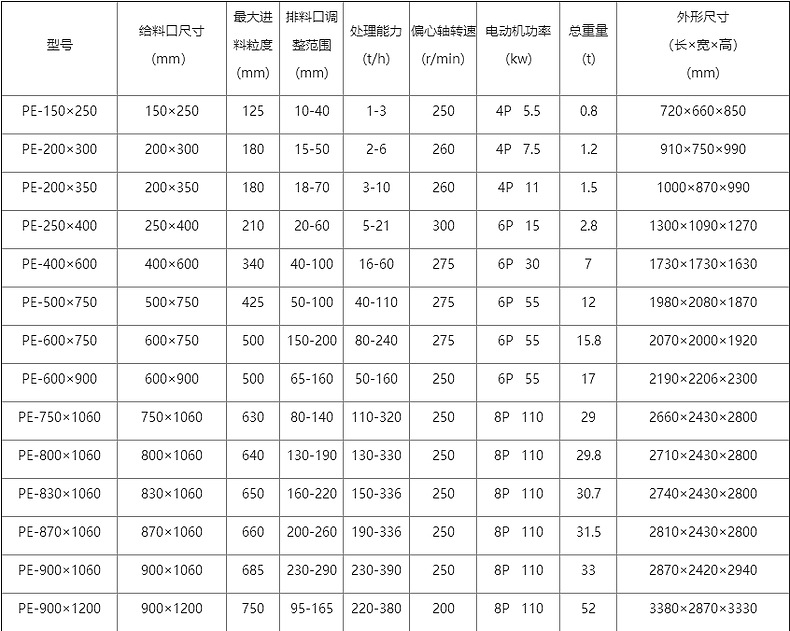

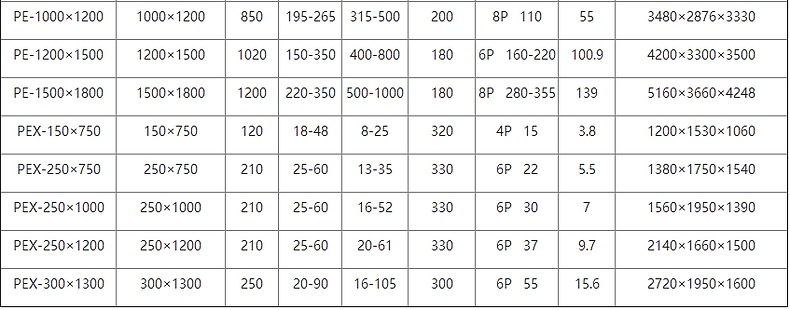

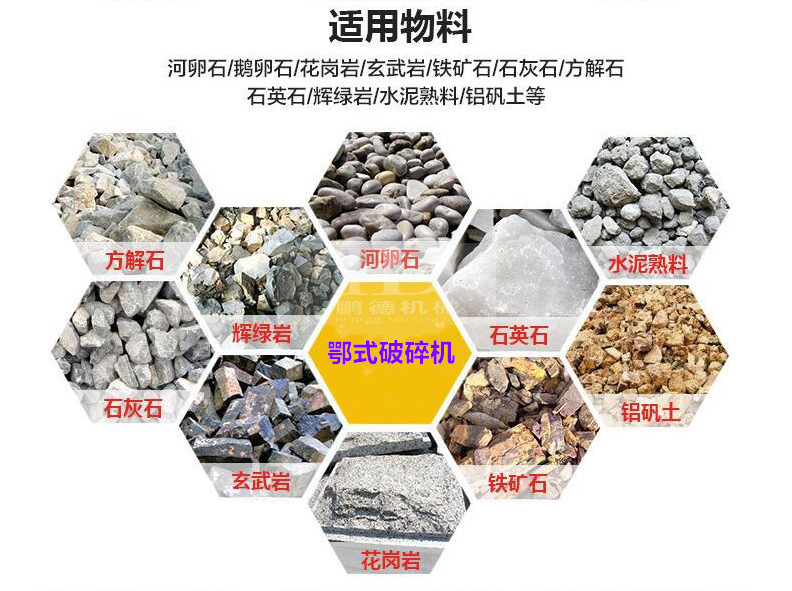

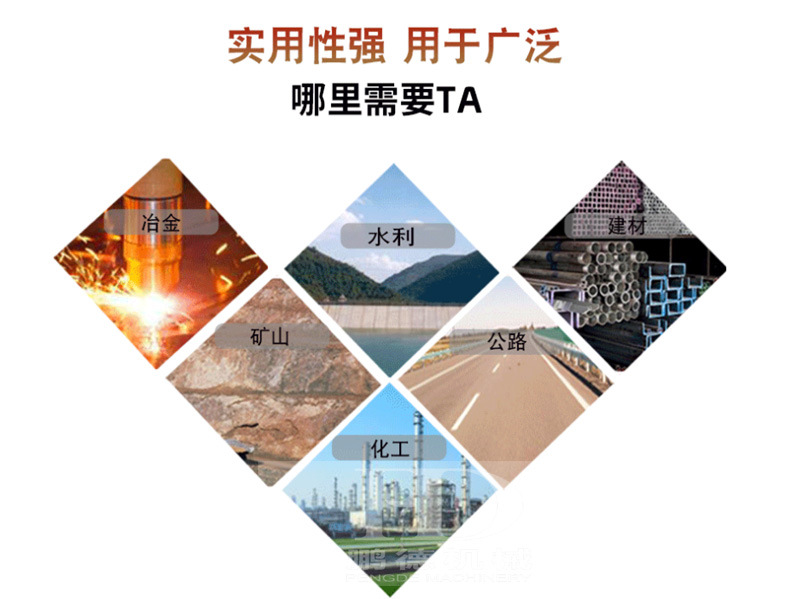

Jaw Crusher This technology is relatively mature and widely used Crushing equipment 。 This series of crusher is a coarse crushing equipment, which is used in many industries such as mining, metallurgy, building materials, highway, * * *, water conservancy and chemical industry. The pressure resistance of the crushed material is not more than 320MPa, and the discharge port can be adjusted freely according to the user's needs. The equipment features large crushing ratio, uniform product granularity, simple mechanism, reliable performance, electric machinery Small power, energy conservation and environmental protection, low noise, small dust, economic operation and other advantages.

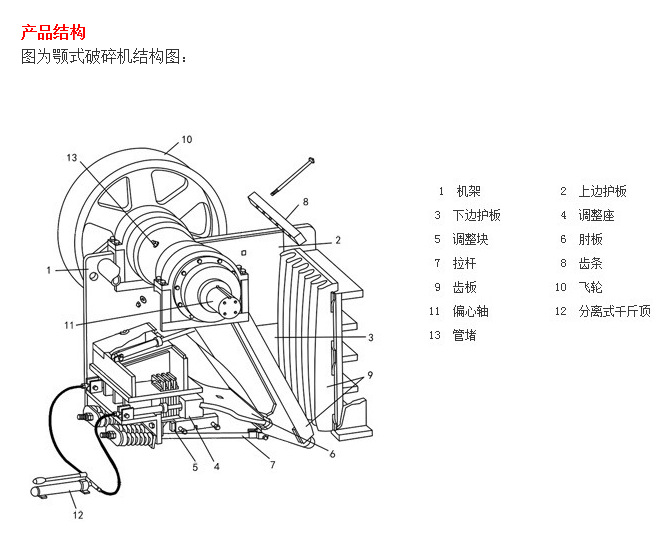

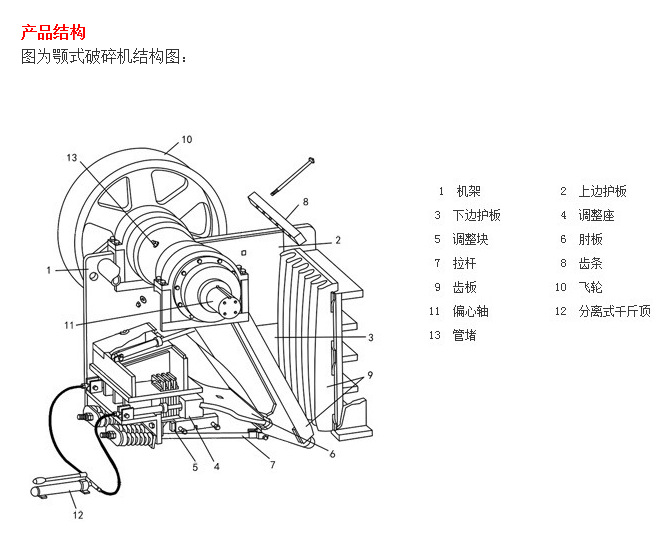

The crushing part of jaw crusher is composed of moving jaw plate and fixed jaw plate. Materials are crushed between the moving jaw plate and fixed jaw plate. The moving jaw plate and the fixed jaw plate need to bear huge crushing force and friction, so they are easily damaged. In order to protect the jaw plate, relevant people will recommend installing wear-resistant tooth shaped lining plate on its surface, which is also called guard plate. In addition to squeezing, it also has bending effect on crushed materials, thus improving the crushing effect.

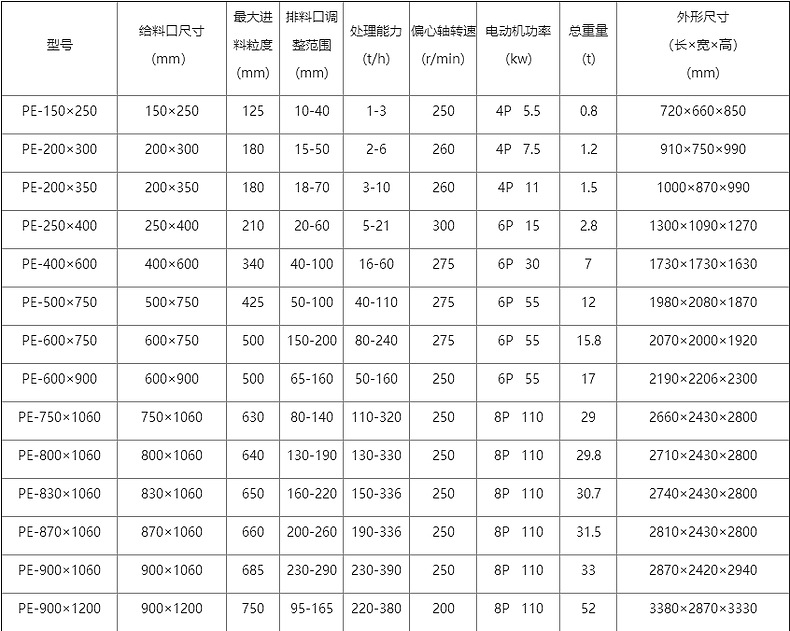

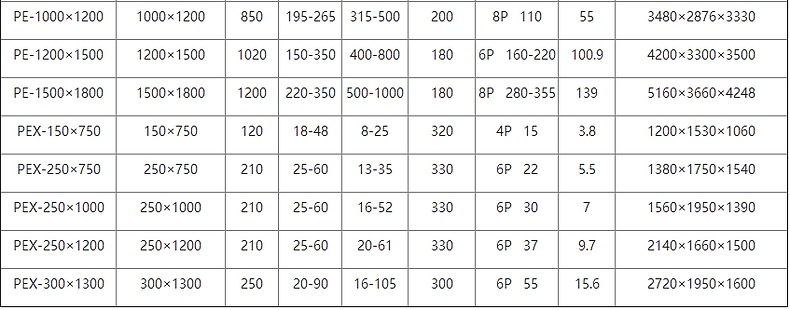

The working mode of jaw crusher (jaw crusher) is curved extrusion type. The machine mainly uses the moving jaw plate to make periodic reciprocating movement against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, large blocks and strangely shaped lime The rock enters the crushing chamber, and the finished products are discharged from the bottom after crushing; When approaching, the limestone installed between the two jaw plates will be crushed by squeezing, bending and splitting. In the process of crushing, it can be divided into coarse crushing and fine crushing. The limestone jaw crusher adopts advanced technology and optimizes the Feeding equipment Therefore, the feeding particle size is increased, and the particle size can be 125mm~750mm, which is the preferred equipment for primary crushing.

Unique advantages of jaw crusher

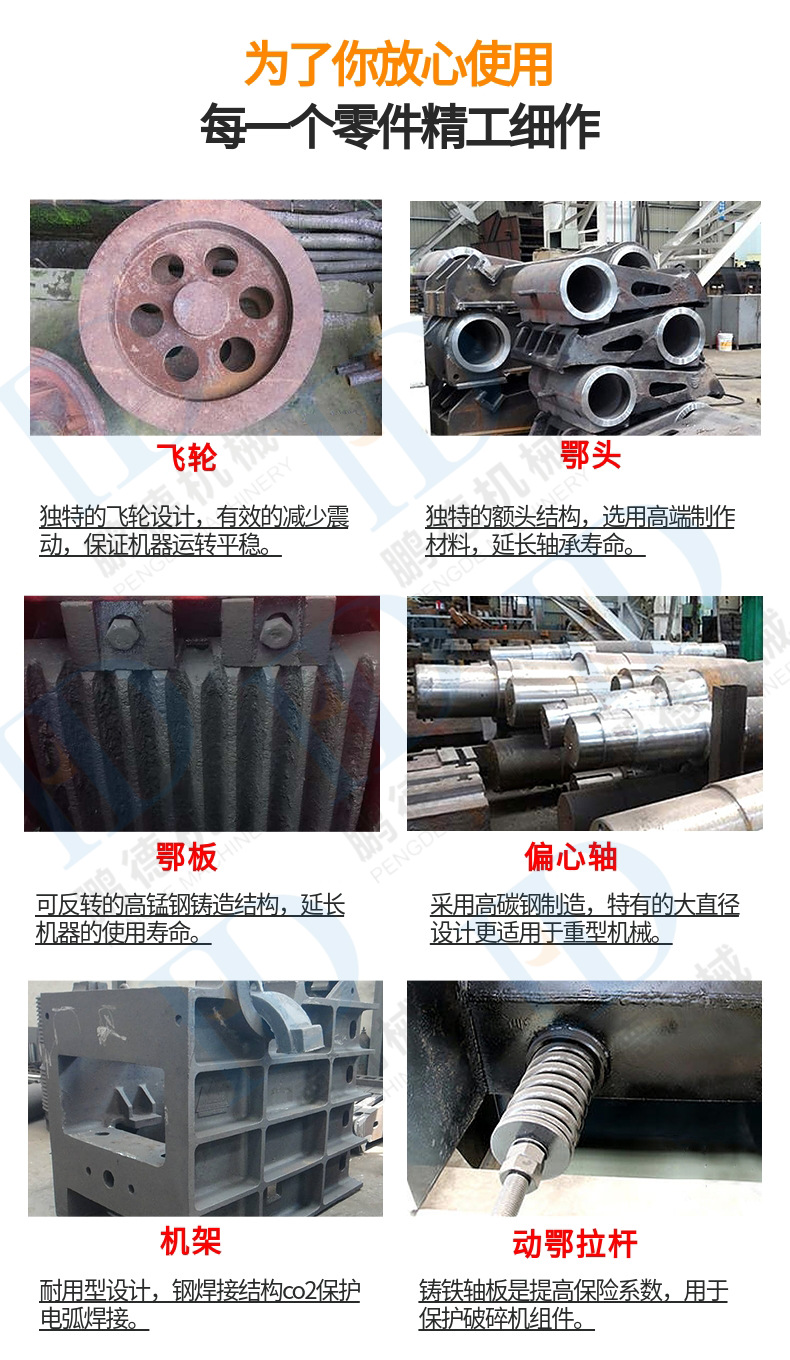

● Short bracket

● Low suspension

● Large swing angle

● Long service life

● Convenient maintenance

1. The crushing chamber is deep and free of dead zone, improving the feeding capacity and output;

2. Simple structure, easy to find fault causes in case of problems, easy to maintain and repair;

3. Low price, high cost performance, more easily accepted by customers;

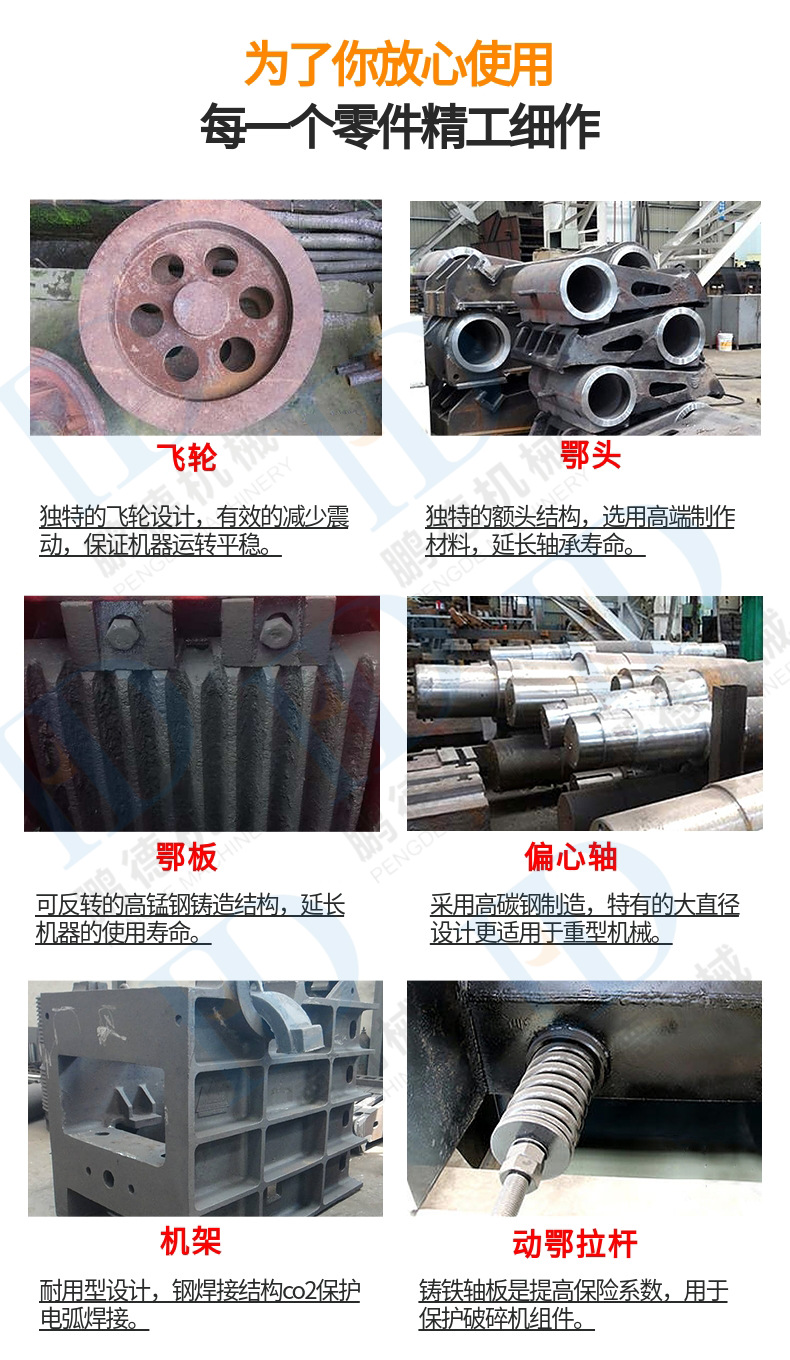

4. Jaw plate is made of hard wear-resistant material with long service life;

5. The shim type discharge outlet adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment;

6. The discharge port has a wide adjustment range, which can meet the requirements of different users.

Henan Pengde Machinery Equipment Co., Ltd. is a professional manufacturer mainly engaged in aggregate production, construction sand, urban construction waste treatment and other comprehensive supporting equipment processing. The company mainly produces crushing equipment, sand making equipment, screening and washing equipment, transportation and environmental protection equipment and other professional technical performance, which are among the top domestic products of the same kind and widely used in various industries such as mining, cement, roads, power, metallurgy, coal, etc. The company has won unanimous praise from customers at home and abroad for many years. Henan Pengde Machinery Equipment Co., Ltd. adheres to the enterprise purpose of "pragmatic innovation, honesty, superior quality, and five-star service", aims to serve customers, satisfy customers, and design appropriate production plans for customers, and adheres to the development philosophy of "careful design, excellent production, and sincere service", Win win cooperation with customers and make progress hand in hand.

1. The jaw crusher can only be fed for production after a few minutes of normal operation, and a buffer time should be given to the equipment.

2. When using the feeding device to feed mineral materials, it is necessary to align with the crushing chamber to avoid the feeding pulley or clamping on the transmission part. Overfeeding is not allowed. The jaw crusher has its own bearing capacity and should be fed within the range of feeding amount and feeding particle size.

3. After the normal operation of the jaw crusher, always observe the temperature of the bearing. When the bearing temperature exceeds 70 degrees, the whole machine will not work properly, and it is necessary to stop the machine immediately for treatment, otherwise it is easy to cause faults.

4. When processing is completed and the machine is ready for shutdown, it is necessary to ensure that there are no remaining untreated materials in the machine before turning off the power supply, otherwise it is easy to cause blockage in the machine and cause equipment failure.

5. When the jaw crusher is running, in case of failure, the power should be turned off immediately to stop the crusher, and the materials should be cleaned up. After cleaning up, the crusher can run again.

6. To ensure that the jaw crusher can achieve high yield and high income, the equipment should be regularly maintained, the use of the equipment should be regularly checked, especially the wear of vulnerable parts, and the maintenance records should be made.

![Jaw crusher @ Fanke Kuaitou [kt. fkw. com]](https://cbu01.alicdn.com/img/ibank/2019/687/761/11293167786_1363350618.jpg)