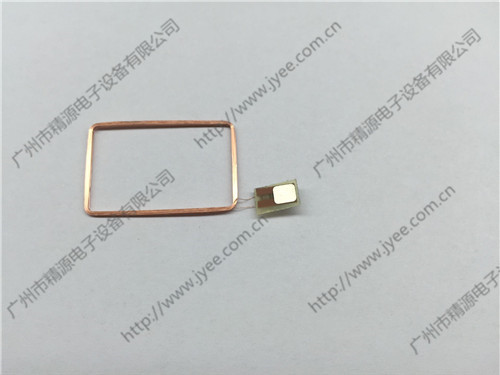

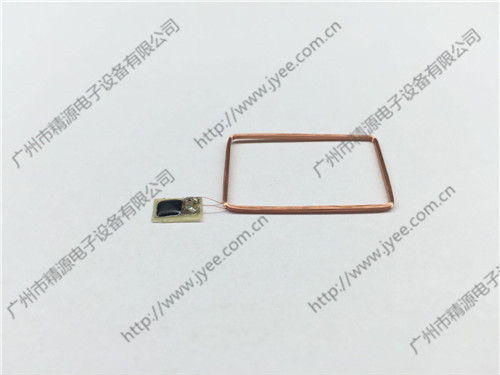

Enameled wire Accurate inverter DC is directly adopted for terminal welding mash welder welding Melt the enameled wire and the terminal indicator together without adding any auxiliary solder. In the previous enameled wire welding industry, most of them used tin welding. With the improvement of customers' quality requirements, the traditional manual welding in this industry has been gradually eliminated and has been completely eliminated mash welder Replaced by.

Features of IC chip welding, enameled wire and IC chip welding machine :

1. The welding is firm and the drawing force can fully meet the customer's requirements;

2. Small deformation, small indentation and beautiful welding;

3. Adopt constant current, constant pressure, constant power, constant pulse width control mode for stable welding;

4. Cost saving and fast welding efficiency;

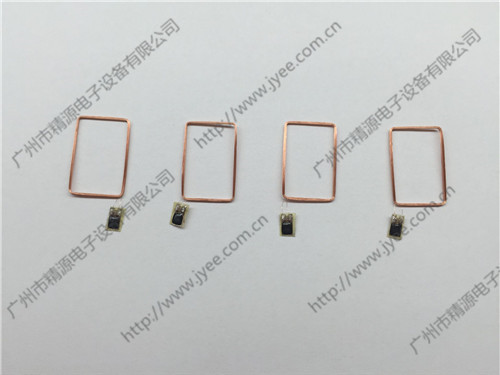

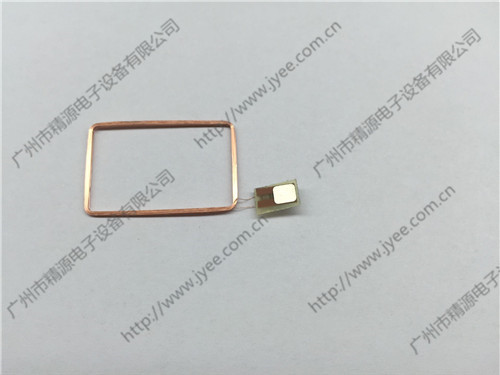

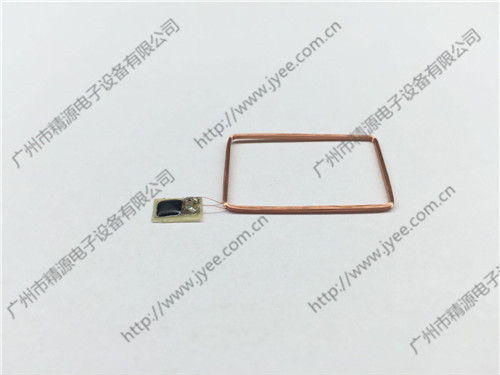

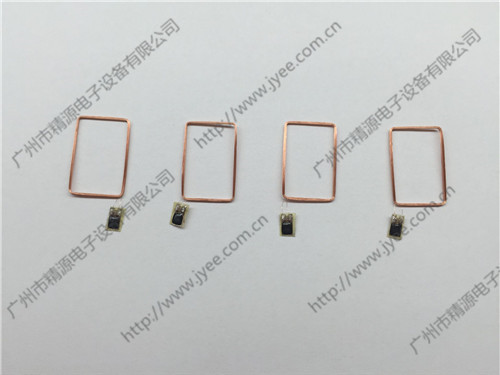

Application picture:

Precautions for use environment:

1. Avoid using at high temperature, high temperature, vibration and shock;

2. Avoid metal dust and welding spatter entering the cabinet;

3. Do not store and use in corrosive atmosphere or drug environment;

4. Avoid using near high temperature sources;

Accurate inverter DC resistance welding principle:

1. After the weldment is assembled, the pressure is applied through the electric comparator, and the current is used to pass through Connector Resistance welding refers to the welding method of resistance heat generated on the contact surface and the adjacent area of. Resistance welding includes resistance spot welding, resistance projection welding, resistance seam welding and resistance butt welding. It is characterized by high production efficiency, low cost, material saving and easy automation. Therefore, it is widely used in various industrial departments such as aviation, aerospace, energy, electronics, automobile and light industry door , is one of the important welding processes.

2、

Factors influencing resistance welding quality |

Influence of welding current | The influence of current on heat generation is greater than that of time and pressure. Therefore, in the welding process, it is a parameter that must be strictly controlled. The welding current is too small to form a core or the size of the core is small, and the strength of the welding point is small; If the welding current is too large, the welding workpiece will overheat, splash, and the indentation will be too deep. |

Influence of welding time | In order to ensure the size and strength of the solder joint, the welding time and welding current can complement each other within a certain range. In order to obtain a certain strength of solder joints, high current and short time (strong condition, also known as hard specification) can be used, or low current and long time (weak body condition, also known as soft specification) can be used |

Influence of electric pressure | The electric pressure has an obvious effect on the total resistance between the two electric comparators. The electric pressure is small, which is easy to generate splash. With the increase of the electric pressure, the total resistance decreases. When the electric pressure increases and the welding current remains unchanged, it cannot compensate for the decrease of heat production caused by the decrease of total resistance. Therefore, the strength of the welding spot decreases with the increase of the welding pressure. The solution is to increase the welding current while increasing the pressure. |

Influence of electric shape and material properties | Since the contact area of the electric comparator determines the current density, and the resistivity and thermal conductivity of the electric comparator material affect the generation and loss of heat, the shape and material of the electric comparator have a significant impact on the formation of nuggets. With the deformation and wear of the electric coupler end, the contact area increases and the strength of the solder joint decreases. |

LCD inverter DC resistance welding characteristics JYEE | Guangzhou Jingyuan Electronics |

1. DC output. The welding current is pulsating DC (and the waviness is small), without the disadvantage of AC zero crossing discontinuous heating of the workpiece. The heat is concentrated, which improves the welding thermal efficiency Metallic materials It is especially suitable for welding with some difficult welding materials. The welding process is stable and the welding quality is significantly improved. At the same time, the electrical life is extended.

2. It is controlled by MCU and has the function of current, voltage and power monitoring.

3. The inverter bridge adopts soft switching technology to reduce switching loss and electromagnetic interference.

4. It has fault diagnosis and emergency signal startup functions such as current abnormality, monitoring value overrun, network voltage overrun, overheating, etc.

5. When the inverter bridge current is abnormal, it automatically turns off to enhance system protection.

6. Three stage heating setting, with current slow rise and slow fall function, wide time range setting (0-250ms or 0-1s), suitable for complex welding process needs.

7.20 sets of parameters are stored to facilitate the use of various welding varieties.

8.240x128 LCD display, displaying multiple contents at the same time.

9. Strong external communication function: welding end, fault, counting signal, RS-232 data communication port (optional), convenient for automatic welding.

10. EEPROM is used for data storage, without battery life problem.

11. Fast response. Due to the high inverter frequency (4kHz, 1kHz), the inverter frequency of specific models of machines can be referred to Table 1. The power on time control cycle is 0.25ms or 1ms, which is 80 or 20 times higher than the 20ms of the common AC welding machine, and the control accuracy is significantly improved. Compared with the capacitor energy storage welding machine, it does not need charging and discharging, and its controllability is significantly enhanced. It is especially suitable for the welding of accurate parts and high-quality, high-precision and high-speed welding.

Product picture:

LCD inverter DC resistance welding power supply JYD-01L/01AL parameter

model | Input voltage (V) | Rated power (kVA) | Large output current (DCA) | control model | Load duration rate (%) | Inverter frequency (kHz) |

JYD-01L

/01AL | 220V&

3~380V | four | one thousand | Constant current/constant power/constant voltage/constant pulse width | twenty | four |

Welding cycle period | Number of welding pulses | Current ramp up and ramp down control | Number of stored welding specifications | Overall dimension (mm) (L * B * H) | Weight (kg) |

eleven | three | yes | 20 groups | 435*185*320 | 18/19 |

LCD inverter DC resistance welding power supply JYD-02L/02AL parameter

model | Input voltage (V) | Rated power (kVA) | Large output current (DCA) | control model | Load duration rate (%) | Inverter frequency (kHz) |

JYD-02L

/02AL | 220V&

3~380V | six | two thousand | Constant current/constant power/constant voltage/constant pulse width | twenty | four |

Welding cycle period | Number of welding pulses | Current ramp up and ramp down control | Number of stored welding specifications | Overall dimension (mm) (L * B * H) | Weight (kg) |

eleven | three | yes | 20 groups | 435*185*320 | 20.5/22 |

LCD inverter DC resistance welding power supply JYD-03L/03AL parameters

model | Input voltage (V) | Rated power (kVA) | Large output current (DCA) | control model | Load duration rate (%) | Inverter frequency (kHz) |

JYD-03L

/03AL | 220V&

3~380V | ten | three thousand | Constant current/constant power/constant voltage/constant pulse width | twenty | four |

Welding cycle period | Number of welding pulses | Current ramp up and ramp down control | Number of stored welding specifications | Overall dimension (mm) (L * B * H) | Weight (kg) |

eleven | three | yes | 20 groups | 435*185*320 | 22/24 |

Three reasons for choosing Guangzhou Jingyuan JYEE |

Our advantages

1. High tech enterprises

2. It has an innovative R&D team consisting of several doctors and masters with the core of Dr. Liu De

3. With more than 30 years of experience in R&D of resistance welding equipment, the chief engineer is the deputy director of the National Pressure Welding Committee

4. More than ten * * * items

5. More than 100 relevant technical papers were published, and more than 50 papers were included in EI and SCI

Accurate manufacturing

1. Strictly control the quality of incoming materials

2. Imported brand core components

3. Design for customer application objects, and tailor accurate resistance welding equipment suitable for customer applications

4. Complete production plan and short delivery period

5. Dynamically manage the whole production process to ensure product quality

good service

1. Free pre-sales technical support, process test, design solutions

2. The company has a number of qualified relevant personnel in the welding industry who are skilled in welding technology and can provide long-term and complete process technology services

3. There are many after-sales service outlets, which can quickly respond to service customers

4. 7 × 24 technical support contact information

5. Closely follow up the application of the sold equipment to fully ensure that customers can use the equipment purchased in our company

Guangzhou Jingyuan JYEE after-sales service commitment |

In order to let you have no worries when using our products, we promise the following for the accurate inverter power products produced by Guangzhou Jingyuan JYEE and sold in mainland China:

1. Honest and law-abiding operation, no counterfeiting

2. All products will be delivered after passing the full inspection and test

3. Deliver the products to the destination safely according to the agreed delivery method

4. For your feedback to us: whether it's suggestions or complaints, we will reply within 24 hours

5. We will provide necessary technical training on products for users' power supply maintenance and management free of charge, including

(1) Product commissioning

(2) Precautions in product use

(3) Basic requirements for product use and maintenance

6. Create user files; Follow up the use of products for a long time; Help users to establish perfect production process and provide integrated technical support for users in a timely manner.

Guangzhou Jingyuan Electronic Equipment Co., Ltd. is a high-tech enterprise specialized in the R&D, production and sales of high-precision spot welding machines, pulse hot press, high-frequency spot welding machines, touch welding machines, inverter spot welding power supplies, pulse hot press welding machines, hot bar machines, seam welding power supplies, micro arc spot welding power supplies, etc. Guangzhou Jingyuan Electronic Equipment Co., Ltd. is equipped with accurate inverter spot welding machines (touch welding machines), hot press welding machines and seam welding machines of various powers in the factory Besides, there are hundreds of fixtures suitable for different products (fixtures can also be designed according to the product). No matter any product of your company has welding difficulties, Guangzhou Jingyuan JYEE sincerely welcomes you to come to our company (or send the workpiece to our company) for welding and proofing. We have a research and development group consisting of a group of welding related personnel, professors, postdoctors and doctors for 30 years of "resistance welding research" And a high-level understanding of the welding process can help you find a better welding solution.

Guangzhou Jingyuan Electronic Equipment Co., Ltd

contacts: Chen Gong

Mobile:***

Tel: (8620) - 82222862

Fax: (8620) - 82227112

Business address: 6th Floor, Building B, No. 188 Kaiyuan Avenue, Science City, Guangzhou Hi tech Industrial Development Zone