Sand blasting machine is a category of air conveying machinery. It is to use compressed air to transport powdery particles (1~4mm in diameter) from one place to another in the pipeline. During the process of converting kinetic energy into potential energy, the sand particles moving at a high speed will wash the surface of the object, so as to improve the surface quality of the object. How to screen sandblasting machines? 1. Depending on the size of the workpiece, choose box sandblasting machine, mobile sandblasting machine, and automatic sandblasting machine; 2. Depending on the shape of the product, choose the sandblasting machine

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/02

Sand blasting hose is mainly used for conveying solids containing particles such as particles, gravel, cement, quicksand, concrete, gypsum, etc. It is suitable for various tunnel works, tunnels, caverns and other engineering operations. The inner rubber and outer rubber of sand blasting pipe are usually made of wear-resistant materials, most of which are NBR (copolymer), SBR (oil filled styrene butadiene rubber), or PARA rubber (trefoil rubber) with better performance of imported hose. It is widely used, mainly

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

Abrasion resistance standard of sandblasting hose: this is also the main basis for judging whether the quality of sandblasting hose is good or bad. In the current standard, according to the method of ISO4649, the wear volume of sandblasting hose should not exceed 140MM&SUP3. In addition, the strength of interlayer bonding, ozone resistance index and mechanical properties (under verification pressure) of sandblasting hose are also important indicators for the quality consideration of sandblasting hose. The main structure of sandblasting hose includes feeding system and circulation system

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

The application of sand blasting can clean the surface of glass mold, rubber mold, metal casting and extrusion parts; It can realize the function of trimming weld; Next, for sand blasting, it can realize the surface glaze of the workpiece, remove the oxide skin on the surface of the workpiece, and remove the color difference (castings, forgings) after merging during the processing; Able to clean large turbines, engine castings or complicated small parts. In the process of sand blasting machine processing, the main reasons that affect the processing efficiency and effect include the stability of air pressure

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

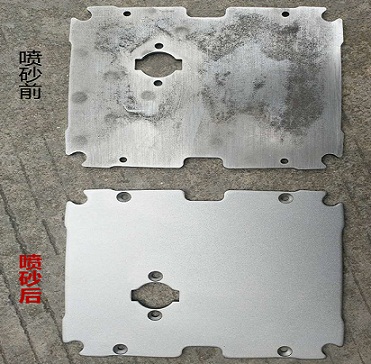

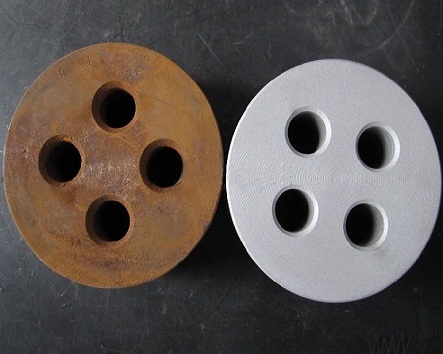

The pretreatment stage of sand blasting process refers to the treatment that should be carried out on the workpiece surface before the workpiece is sprayed and coated with protective layer. The quality of sand blasting pretreatment affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If the pretreatment is not done well, the corrosion will continue to spread under the coating, making the coating flake off. Sand blasting: compare the coating of carefully cleaned surfaces with that of generally simple cleaned workpieces by exposure method, and the service life is comparable

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

The main purpose of the sandblasting machine is sandblasting cleaning, which is a process widely used in machinery manufacturing. All forged, cast, heat treated and surface treated parts must be sandblasted to remove the oxide skin, sand, old coating and molten salt heat on the surface. Rust, etc. (1) Cleaning of workpiece surface, oxide scale, residual salt, residual oil, etc. after heat treatment; Oxide skin and molding sand of black (or colored) castings; Scale

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

The ideal working condition requires that the sand particles present a uniform suspended flow state in the pipeline. The appropriate sand supply amount, appropriate air volume and air pressure are the key factors to determine the flow effect of sand particles. The air volume should be such that the flow rate of air in the pipeline is at least greater than the settling speed of large sand particles. The air pressure is sufficient to overcome the friction loss and resistance of air pushing the sand particles to flow in the pipeline, This can ensure smooth flow of sand particles in the pipeline. However, as the pipeline grows, the wind pressure gradually decreases

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 10/01

The use of sand blasting can also realize the cleaning of parts (such as cylinder block, piston and spark plug) during engine maintenance; It can clean the surface of brushes, contactors and wiring techniques to improve the conductivity; It can also realize the cleaning and preservation of parchment and others; Later, for sand blasting, old paint and dirt on the surface of the workpiece can also be removed. Sand blasting function: sand blasting is powered by compressed air to form a high-speed jet beam to spray materials (copper ore, quartz

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

Sand blasting: the service life of the coating on the surface that has been carefully cleaned can be 4-5 times longer than that on the workpiece that has been simply cleaned. There are many methods for surface cleaning, but the commonly accepted methods are: solvent cleaning, pickling, manual tools, power tools. Sand blasting function: sand blasting is to use compressed air as the power to form a high-speed jet beam to spray materials (copper ore, quartz sand, carborundum, iron sand, sea sand) to the surface of the workpiece to be treated at a high speed, so that

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

Due to the impact and cutting effect of abrasive on the workpiece surface, the sandblasting machine can make the workpiece surface obtain a certain degree of cleanliness and different roughness, and improve the mechanical properties of the workpiece surface, thus improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, extending the durability of the coating, and also conducive to the leveling and decoration of the coating Remove the noise and oxide layer, coarsen the surface of the medium, eliminate the residual stress of the workpiece and improve the surface of the substrate

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

The ideal working condition requires that the sand particles present a uniform suspended flow state in the pipeline. The appropriate sand supply amount, appropriate air volume and air pressure are the key factors to determine the flow effect of sand particles. The air volume should be such that the flow rate of air in the pipeline is at least greater than the settling speed of large sand particles. The air pressure is sufficient to overcome the friction loss and resistance of air pushing the sand particles to flow in the pipeline, This can ensure smooth flow of sand particles in the pipeline. However, as the pipeline grows, the wind pressure gradually decreases

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

Classification of sandblasting hose: different types of sandblasting hose have different functions. Its classification can be divided into three categories. Class II sandblasting hose is electrically connected, and Class II marked "M" refers to sandblasting hose with conductive rubber layer. The third type is non-conductive ordinary sandblasting hose, marked "A". Sand blasting hose is mainly used for conveying fluid containing solid particles such as particles, gravel, cement, quicksand, concrete, gypsum, etc. It is suitable for various tunnel projects, tunnels, caverns, etc

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

Sand blasting rubber hose, also known as rubber hose for sand blasting, is suitable for air pressure sand blasting and rust removal on metal surfaces, hemp removal, and sand blasting rubber hose for wet sand blasting and dry sand blasting in engineering construction. The common application fields are shipbuilding, machining and spraying industries. Wear resistance standard: This is also the main basis for judging whether the quality of sandblasting hose is good or bad. In the current standard, according to the method of ISO4649, the abrasion volume of sand blasting hose shall not exceed 140MM&SU

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/30

Main structure of manual sandblasting machine 1. sandblasting chamber: sandblasting chamber is one of the main components of sandblasting machine, which is mainly made of hot rolled plates. There are also customized boxes made of stainless steel and fiberglass. The size of sandblasting chamber depends on the size of the product. For example, if your workpiece is 400 in length, 200 in width and 300 in height, then the number of boxes you choose is less than 600 in length, 500 in width and 550 in height. Of course, there is generally no such model in the market. Most manufacturers have several types of box sandblasting machines

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

Sand blasting machine is a modern, cost-effective casting cleaning equipment with high efficiency and low investment. Sand blasting machine is usually used for rust removal and derusting of easily corroded materials or workpieces, and descaling of non rusty metals. In daily work, the operating procedures of the sandblasting machine are directly related to the safety of production. Sand blasting machine failure resolution Sand cylinder does not (1) check the pressure of the pressure gauge; (2) Check whether the pipe is connected incorrectly; (3) Check whether the small rubber band is damaged. Treatment method: (1) Increase air pressure

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

Classification of sandblasting hose: different types of sandblasting hose have different functions. Its classification can be divided into three categories. Class II sandblasting hose is electrically connected, and Class II marked "M" refers to sandblasting hose with conductive rubber layer. The third type is non-conductive ordinary sandblasting hose, marked "A". Abrasion resistance standard of sandblasting hose: this is also the main basis for judging whether the quality of sandblasting hose is good or bad. In the current standard, according to the method of ISO4649, sandblasting hose

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

In terms of hydraulics, the standards are as follows. The working pressure of sand blasting hose is 0.63MPa. When it carries out the hydraulic test work under twice the working pressure, no water seepage, local bulge, expansion and other abnormal phenomena are allowed. Classification of sandblasting hose: different types of sandblasting hose have different functions. Its classification can be divided into three categories. Class II sandblasting hose is electrically connected, and Class II marked "M" refers to sandblasting hose with conductive rubber layer. And the third one is

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

The advantages of sandblasting include: metal parts after sandblasting are basically not damaged, and the dimensional accuracy will not change; The surface of the part will not be polluted, and the abrasive will not react with the material of the part; It is easy to deal with grooves, recesses and other hard to contact parts, and a variety of abrasive grains can be used. The application of sand blasting can clean the surface of glass mold, rubber mold, metal casting and extrusion parts; It can realize trimming weld

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

Sand blasting: due to the impact and cutting effect of the abrasive on the surface of the workpiece, the surface of the workpiece can obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the surface of the workpiece can be improved, thus improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, extending the durability of the coating, and also conducive to the leveling and decoration of the coating. Sand blasting: it can remove rust, and sand blasting is mainly a high-speed spraying method formed by the principle of air compression

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/29

Sand blasting function: sand blasting is to use compressed air as the power to form a high-speed jet beam to spray materials (copper ore, quartz sand, carborundum, iron sand, sea sand) to the surface of the workpiece to be treated at a high speed, so that the surface or shape of the workpiece changes. Sand blasting: due to the impact and cutting effect of abrasive on the workpiece surface, the workpiece surface can obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the workpiece surface can be improved, thus improving the fatigue resistance of the workpiece

Shenyang Jichengtong Machinery Equipment Co., Ltd

two thousand and twenty-three 09/28