Dr. Olena Zhu, Senior Chief Engineer and AI Solution Architect of Intel Client Computing Business Unit

For decades, we need to combine science and art to decide to place thermal sensors on Intel clients processor Where.

Circuit designers will refer to historical data to determine the placement of thermal sensors in the central processor of modern notebook computers( CPU )Which position of the. They will also rely on experience to determine the areas where hot spots are likely to occur. This complex process can take up to six weeks to test, including simulating the workload, optimizing sensor locations, and then restarting the entire process.

Today, thanks to a new enhanced intelligence tool developed internally by Intel engineers, designers of system level chips do not have to wait six weeks to know whether they have found the best location of the sensor. They can get the answer in a few minutes.

A small step for enhanced intelligence and a big step for chip design

This tool was developed by the enhanced intelligence team led by Dr. Olena Zhu, senior chief engineer of Intel Client Computing Business Unit and AI solution architect. This tool helps Intel's system architects incorporate thousands of variables into future chip designs. This is just one of many examples where the Intel team uses AI knowledge to optimize various workloads.

Enhanced intelligence is a subset of artificial intelligence, which focuses on how humans and machines work together.

Mark Gallina, Chief Engineer and Senior System Thermodynamics and Mechanical Architect of Intel Client Computing Business Unit, said, "Client products like laptops rely heavily on Remax and peak frequency. We hope SoC can break through to higher frequency, which in turn will generate heat."

He explained in detail how engineers must accurately analyze complex and concurrent workloads that activate CPU core, input/output (I/O) and other system functions to accurately determine the location of hot spots. What makes this process more complicated is to determine where to place the tiny thermal sensors, each of which is only slightly larger than the ordinary pin tip you use.

Gallina said, "This process takes several weeks, and we can only study one or two workloads at a time."

Intel's new enhanced intelligence tools address these speculative tasks. Engineers input their boundary conditions. This tool can process thousands of variables and return the ideal design proposal in a few minutes.

Engineers have applied this tool in the SoC design of Intel Core Ultra mobile processor family (Meteor Lake). Meteor Lake will be officially released on December 14, 2023. At the same time, this tool will also be used in future client products such as Lunar Lake and its successor products, which will help to further expand the AI PC level notebook product line.

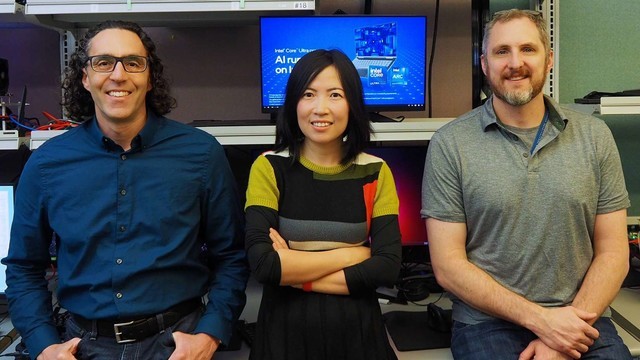

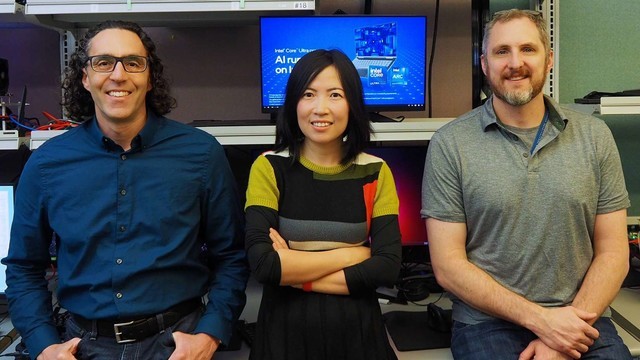

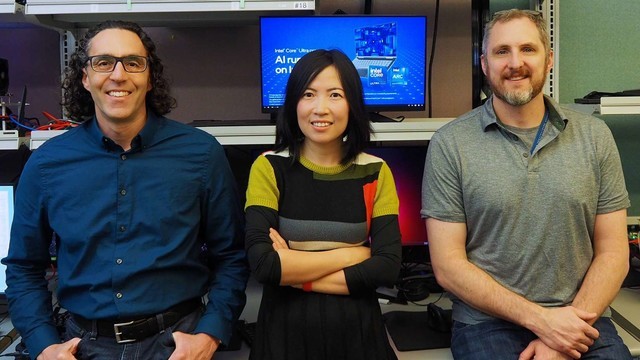

Members of Intel's enhanced intelligence team, starting from the left: Mark Gallina, Olena Zhu and Michael Frederick, Intel's Client Computing Business Unit Laboratory in Hillsborough, Oregon

More AI: Use enhanced AI to identify thermal workloads to optimize chip design

Olena Zhu and her team members, chief engineer and AI solution architect Ivy Zhu also developed a supporting tool that can quickly identify critical thermal workloads.

Olena explained that its working principle is as follows: her team trains AI models based on the simulation or measurement results of a few workloads. These AI models can then predict other workloads that Intel has not yet simulated or measured.

These two enhanced intelligence tools have jointly improved engineers' ability to optimize the chip design of future Intel processor series, including drive The client processor of the next generation AIPC.

Although both tools are very useful and error free, enhanced intelligence will not replace real engineers in the short term.

Gallina said: "By enhancing intelligence, we combine computer learning and ergonomic expertise to ensure that our limited resources are put into the best areas."

"This new tool has revolutionized the way we deal with heat at present. It is more efficient, and before we start the SoC, it can let us have a clear understanding of hot wind risk. We have been groping in the dark before, but now, with enhanced intelligence, it is like we have a flashlight, illuminating the way forward."

Enhanced intelligence helps precise work similar to "looking for a needle in a haystack"

A few years ago, Olena was surprised to realize that the rapid progress of AI investment has opened a new door for Intel's design work.

Olena said: "Using a new type of tools brought by enhanced intelligence, we can process data more effectively than ever before. When we combine artificial intelligence with existing excellent engineering strength, we can more effectively locate and process massive data accurately and quickly."

Thanks to the efforts of Olena and his team, Intel's engineers are committed to developing AI. The enhanced intelligence team of Intel's client computing division continues to look for AI accelerated hardware and Software The following progress has been made:

For fast and accurate signal integrity analysis tools for high-speed I/O, the design time is shortened from several months to one hour. Intel is the first company in the industry to adopt this technology, which has supported the design of multiple generations of chips.

The automatic fault analysis tool based on artificial intelligence is used for high-speed I/O design. Since its deployment in 2020, the design efficiency has increased by 60%.

The enhanced intelligent tool named "AI Assist" can automatically determine the customized overclocking value of different platforms using the AI model, reducing the preparation time required for overclocking from several days to one minute. Now, products equipped with the 14th generation of Core processors will provide the "AI Assist" tool. (Video: How AI Assist makes overclocking easier through machine learning)

The automatic silicon wafer layout design optimizer based on artificial intelligence was incorporated into Intel's SoC design process.

An intelligent sampling tool can help power and performance engineers deal with intelligent design experiments, reducing the number of test cases by 40%.

An artificial intelligence model built by user interaction tools to predict the performance of architecture solutions and help solve the balance problem of CPU design.

A new way of automatically placing microcircuit board components reduces the cycle time from several days to several hours.

Other engineering teams of Intel also skillfully used AI in Intel's rich product portfolio: Intel hardware thread scheduler algorithm was officially unveiled in the 13th generation Intel Core processor CPU, which increased the workload by more than 20%.

In another example, the engineering team successfully reduced the test time of a single processor by 50% by using the internally developed intelligent AI algorithm.

Olena said: "The trend of integrating AI into similar engineering applications in the industry is growing, and Intel will undoubtedly be happy to accept and make full use of this trend."

This article is an original article. If it is reproduced, please indicate the source: Intel's self-developed AI tool shortens the chip design cycle from weeks to hours https://server.zol.com.cn/866/8666886.html

https://server.zol.com.cn/866/8666886.html

server.zol.com.cn

true

Zhongguancun Online

https://server.zol.com.cn/866/8666886.html

report

four thousand three hundred and eighty-eight

Dr. Olena Zhu, Senior Chief Engineer of Intel Client Computing Business Unit and Artificial Intelligence Solution Architect For decades, we need to combine science and art to decide where to place thermal sensors on Intel client processors. The circuit designer will refer to the historical data to determine which bit of the central processing unit (CPU) of the modern notebook computer to place the thermal sensor in