Because the magnesium alloy solution is easy to oxidize and burn, and its hot cracking tendency is greater than that of aluminum alloy during casting, the melting, pouring and temperature control of die-casting liquid of magnesium alloy are more complicated than that of aluminum alloy die-casting. Die casting machine is divided into hot chamber die-casting machine and cold chamber die-casting machine. The production of hot chamber die-casting machine is about twice that of cold chamber die-casting machine with the same capacity, but its locking force is generally below 7840kn. It is usually used for thin wall castings with low mass (generally below 2kg), such as the magnesium alloy computer shell with an overall dimension of 61 0x61 0nm produced by White Metal Casting Company in the United States, and the Kirt Precision in the United Kingdom The 2.5kg bicycle frames produced by the company are all produced by hot chamber die-casting machine.

The heat dissipation of magnesium alloy has some advantages over that of alloy. For radiators made of magnesium alloy and aluminum alloy with the same volume and shape, the heat (temperature) produced by a heat source is more easily transferred from the root of the radiator to the top of magnesium alloy than that of aluminum alloy, and the top is easier to reach high temperature. That is, the temperature difference between the root and the top of the aluminum alloy radiator is smaller than that of the magnesium alloy radiator. This means that the temperature difference between the air temperature at the root and the air temperature at the top of the heat sink made of magnesium alloy material is larger than that of the heat sink made of aluminum alloy material, so it accelerates the diffusion and convection of the air inside the heat sink and improves the heat dissipation efficiency. Therefore, at the same temperature, the heat dissipation time of magnesium alloy is less than half of that of aluminum alloy.

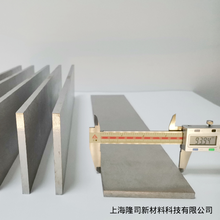

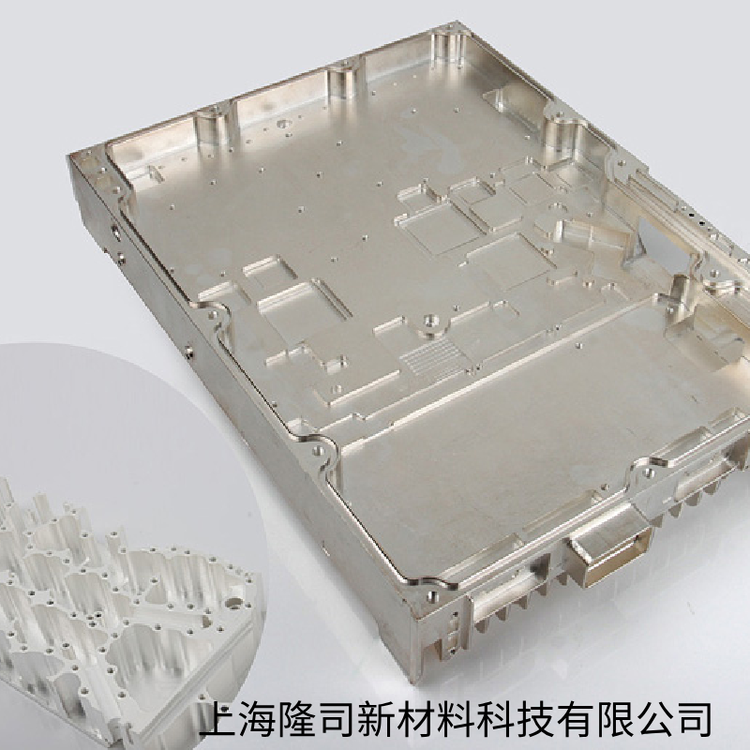

Aluminum magnesium alloy sheet is a typical alloy in Al Mg alloy system, which has the characteristics of medium strength, good corrosion resistance, weldability and easy processing. In foreign countries, aluminum alloy plates in different heat treatment states are the main materials used in automobile manufacturing (car doors, molds, seals) and can making industries. Aluminum plates are widely used in welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tanks, as well as occasions requiring excellent processing performance, excellent corrosion resistance, high fatigue strength, high weldability and medium static strength.

Aluminum plate classification In the world, aluminum materials with thickness of more than 0.2mm, thickness of less than 500mm, width of more than 200mm and length of less than 16m are usually called aluminum plates or aluminum sheets, aluminum foils with thickness of less than 0.2mm, and rows or bars with width of less than 200mm (of course, with the progress of large equipment, there are more rows with width of 600mm).

Aluminum magnesium alloy is composed of two or more metals or nonmetals with metal characteristics. It is generally obtained by melting and synthesizing uniform liquid and solidification. According to the number of constituent elements, it can be divided into binary alloy, ternary alloy and multi-component alloy. China is one of the countries that studied and produced alloys early in the world. Bronze (copper tin alloy) technology was very developed in the Shang Dynasty (3000 years ago); Around the 6th century BC (late Spring and Autumn Period), sharp swords (steel products) have been forged (and overheated). According to different structures, the main types of alloys are: (1) mixed alloy (eutectic mixture). When the liquid alloy solidifies, the components constituting the alloy are crystallized separately, such as solder, bismuth cadmium alloy, etc; (2) Solid melt alloy, the alloy that forms solid solution when the liquid alloy solidifies, such as gold and silver alloy; (3) Metal intermetallic alloy, an alloy in which each component forms a compound with each other, such as brass (β - brass, γ - brass and ε - brass) composed of copper and zinc. Many properties of alloys are better than that of metals, so alloys are mostly used in application materials (see ferroalloys and stainless steels). All types of alloys have the following general characteristics: (1) Most alloys have melting points lower than those of any of their constituent metals; (2) The hardness is greater than that of any metal in its component; (3) The electrical conductivity and thermal conductivity of the alloy are lower than those of any component metal. Using this characteristic of alloys, materials with high resistance and high thermal resistance can be manufactured. It can also be used to manufacture high-performance materials, such as adding 15% chromium and 9% nickel into iron to obtain a corrosion resistant stainless steel, which is suitable for the chemical industry. (4) Some have strong corrosion resistance

Features: The product can remove non-metallic impurities and some metal impurities in magnesium and make the metal composition even during refining. After the furnace charge is completely melted, the lower flux is used for refining. The flux has appropriate surface tension in the air, which can make the flux form a protective film on the surface of magnesium solution. Through exchange, impurities such as potassium and sodium can be removed. When magnesium and magnesium alloy are melted, To prevent combustion oxidation in contact with air, it can react with impurities in magnesium and bring impurities into salts.

Application: suitable for smelting of crude magnesium and magnesium alloy

Usage: Refine the crystalline magnesium and the flux, and the consumption is 1-3%. If the metal is found burning, immediately sprinkle the flux.

Magnesium is one of the light metal elements with abundant reserves on the earth. Its density is small. Its alloy has obvious specific strength of aluminum alloy and steel. Its specific stiffness is much higher than that of engineering plastics, and its wear resistance is better than that of low-carbon steel. Its welding structure has become an important part of civil use and products (1). Weld joint softening rattan alloy can affect the service performance of components. Therefore, people seek various methods to improve the performance of magnesium alloy welded joints [1-2]. The softening problem of welded joints has limitations in terms of both welding process and post weld heat treatment. As an important treatment process to improve the structure and properties of materials, cryogenic treatment has been widely used in traditional steel materials