The solenoid valve can be installed on the hydraulic oil pump flange according to the following steps:

1. Prepare tools and materials: make sure to have proper tools, such as spanners, screwdrivers, torque wrenches, etc., as well as required installation materials, such as bolts, washers and seals.

2. Clean the flange and solenoid valve: before installation, clean the mounting surface of the hydraulic oil pump flange and solenoid valve to ensure that there is no dirt, grease or other impurities.

3. Installing seals: Place appropriate seals, such as O-rings or gaskets, on the flange to ensure the sealing performance after installation.

4. Align the solenoid valve: align the solenoid valve with the mounting hole of the hydraulic oil pump flange to ensure that they are aligned without any offset.

5. Fixing solenoid valve: use appropriate bolts and washers to fix the solenoid valve on the hydraulic oil pump flange. Tighten the bolts evenly with a torque wrench according to the manufacturer's recommended torque value.

6. Connect wires: according to the wiring requirements of the solenoid valve, correctly connect the wires to the terminal blocks of the solenoid valve. Ensure that the wires are firmly connected, and use insulating sleeves or insulating tape to protect the exposed wire parts.

7. Check the installation: after the installation, carefully check the installation of the solenoid valve. Ensure that all connections are secure and free from leaks or looseness.

8. Test function: before starting the hydraulic system, test the function of the solenoid valve. Verify the ability to open and close normally by controlling the power supply or signal of the solenoid valve.

The "oil pump hydraulic flange" is an important component used to connect the oil pump and other components in the hydraulic system. In the hydraulic system, the oil pump is responsible for sucking and pressurizing the hydraulic oil from the oil tank, and then delivering it to various actuating elements, such as hydraulic cylinders or hydraulic motors, through the hydraulic pipeline. The hydraulic flange is used to connect the outlet of the oil pump and the inlet of the hydraulic pipeline to ensure that the hydraulic oil can flow smoothly and generate the required pressure in the system.

High temperature oil pump usually uses high temperature resistant materials, such as stainless steel, cast chromium steel, nickel alloy, etc. These materials have good thermal stability and corrosion resistance, and can work at high temperatures and maintain their performance.

The term "hydraulic oil pump flange" refers to the hydraulic system, oil pump and flange connection. The following is a brief explanation of these concepts:

1. Hydraulic system: The hydraulic system is mainly composed of power components (such as hydraulic pump), actuating components (such as hydraulic cylinder, hydraulic motor), control components (such as direction control valve, pressure control valve, etc.), auxiliary components (such as oil tank, oil filter, cooler, etc.) and hydraulic oil. The system transmits power and signal through hydraulic oil to complete various work tasks.

2. Oil pump: In the hydraulic system, the oil pump is a key component, which is used to suck the hydraulic oil from the oil tank, pressurize it and deliver it to all parts of the system to ensure the normal operation of the system.

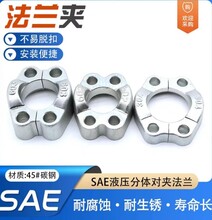

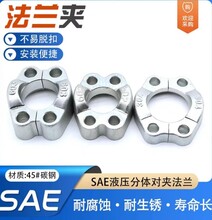

3. Flange: A flange is a connector, usually used to connect two pipes, equipment or other parts. It has a circular or square disc structure, with bolt holes on it. Two flanges are closely connected by bolts to form a sealed connection.

Oil pump flanges are widely used in many fields, mainly including the following aspects:

1. Pipeline connection: in pipeline engineering, flange is used to connect pipeline and gear oil pump. In addition, according to user requirements, the gear oil pump will be equipped with flanges of corresponding materials to connect pipes.

2. Equipment connection: flanges are used to connect various equipment and machinery, such as engines, pumps, compressors, heat exchangers and air conditioning equipment.

3. Marine industry: in the marine industry, flanges are also widely used, including the connection of hull, boiler, steam engine, engine and other parts.

In general, the application scope of oil pump flange covers many aspects of the industrial field, playing an important role in connection, sealing, etc.

The following precautions shall be taken during the use of oil pump flange:

1. The hydraulic oil pump can be installed with a support or flange. The pump and the prime mover should use a common foundation support. Both the flange and the foundation should be sufficiently rigid. Special attention: the plunger pump with flow greater than (or equal to) 160L/min should not be installed on the oil tank.

2. The hydraulic oil pump and the output shaft of the prime mover shall be connected by an elastic coupling. It is forbidden to install a pulley or gear driven hydraulic oil pump on the hydraulic oil pump shaft. If it is necessary to connect the pulley or gear with the pump, a pair of supports shall be added to install the pulley or gear. The coaxiality error between the support and the pump shaft shall not be greater than Φ 0.05mm.

3. The oil suction pipe shall be as short, straight, large and thick as possible, and the oil suction pipe shall be generally equipped with a coarse filter whose nominal flow is not less than twice the pump flow (the filtering accuracy is generally 80~180 μ m). The oil drain pipe of the hydraulic oil pump shall be directly connected to the oil tank, and the oil return back pressure shall not be greater than 0.05MPa. The oil suction pipe orifice and oil return pipe orifice of the oil pump shall be 200mm below the low oil level of the oil tank. Special attention shall be paid to the installation of oil filter on the oil suction pipe of plunger pump. The diameter of the stop valve on the oil suction pipe shall be one stop larger than the diameter of the oil suction pipe. The length of the oil suction pipe L<2500mm, and the number of pipe elbows shall not be more than two.

4. The oil inlet and outlet of the hydraulic oil pump should be firmly installed, and the sealing device should be reliable, otherwise air suction or oil leakage will occur, affecting the performance of the hydraulic oil pump.

5. The self-priming height of the hydraulic oil pump shall not exceed 500mm (or the inlet vacuum degree shall not exceed 0.03MPa). If the makeup oil pump is used for oil supply, the oil supply pressure shall not exceed 0.5MPa. When the oil supply pressure exceeds 0.5MPa, the pressure seal ring shall be used instead. For the plunger pump, the inverted self-priming mode shall be adopted as far as possible.