3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

b、 Scope of application

This resin can be used to replace Scotchcast ™# 241 is used in situations where better mechanical strength, tensile strength, thermal shock and thermal conductivity are required. Applications include filling and sealing of coils, transformers, motors and other power electronic components.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

c、 Usage information

(1) Mix

First mix the two components separately and heat them to 60 ℃ to facilitate mixing. Weigh the two components in the correct proportion (within 2% error) and mix them. Mix well until the color is completely uniform, or until the mixture is completely uniform.

(2) Degassing

In order to remove the gas generated during mixing, air can be pumped under the pressure of 5-10mmHg for 5-15 minutes. Heating to 60 ℃ will help degassing. The vessel wall height shall be 4 times the height of liquid resin to accommodate foam.

(3) Filling and injection

Pour warm resin into the mould preheated to 100 ℃. If the mold is not used, the preheated components can be immersed in the resin. Heat the resin and mold to aid injection. For large filling, air can be pumped under the pressure of 5mmHg for 5-15 minutes, or the mold can be opened after filling and maintaining for several minutes under vacuum.

(4) Curing

If small stress and large seismic resistance are considered, it is recommended to use the curing procedure at a lower temperature. From room temperature to curing temperature, it is recommended to give a heating time.

(5) Storage

The resin system has a storage period of at least one year. Both components shall be stored in a dry and ventilated area, and the container shall be tightly sealed when not in use.

d、 Operation and safety precautions

Before using this product, please read carefully the health hazard warnings and emergency treatment methods on the MSDS and/or chemical labels.

Xiyuan Technology Electronic Materials:

Potting glue: Lodhenhan High Road Corning Dow DuPont, etc. It is widely used in electronic power supply thick film circuit, automobile electronic semiconductor packaging and other industries.

Conductive adhesive: 3M Beijing ablestik Beijing Emerson&Cuming, etc., used in semiconductor LED and other industries

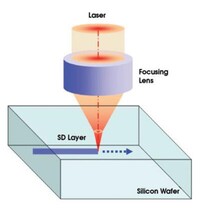

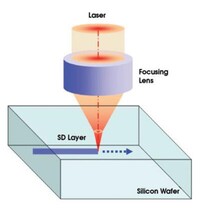

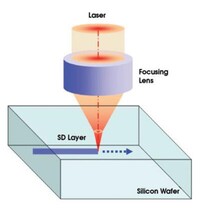

Experimental equipment: provide X-RAY FIB microscope, etc. FBI Musashi Dispensing Machine Nuoxin Dispensing Machine Filling Machine Laboratory Instruments TSV Electroplating Equipment Bonding Machine Parallel Sealing Welder.

Our electronic chemical materials include: adhesive potting material, conductive heat conduction interface material, bare core adhesive material, COB encapsulating material, CSP/Flip chip/BGA, bottom filling adhesive, patch adhesive, electronic coating, UV curing material. The scope of application involves electronic components, electronic components, circuit board assembly, display and lighting, industrial communication, automobile electronic smart card, radio frequency identification, aerospace semiconductor packaging, wafer scribing protection, temporary bonding of liquid crystal circles, thinning of bond alloy wires and other fields.

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

Electronic coating UV curing material Wafer scribing protection Liquid crystal circle Temporary bonding Thinning conductive silver glue Sintering silver nano silver channel Corning COB glue red glue SMT red glue Aviation aerospace glue High temperature resistant potting glue Bond alloy wire insulation coating Bond alloy wire defoaming machine Parallel sealing machine Gluing machine KS Splitter SPT Chopper Chopper Ceramic Chopper Rodham Road Corning Dow X-RAY FIB FBI Musashi Dispensing Machine Nuoxin Dispensing Machine Potting Machine Failure Analysis Fast Packaging Ceramic Shell Package COB Package Chip Bonding Package Cleaning Liquid Crystal Circle Cleaning Solution Silicon Wafer Cleaning Solution Sapphire Cutting Solution Ceramic Scribe Cleaning Solution Chip Adhesive IC Adhesive IC Conductive Adhesive Chip Conductive Adhesive IC insulation glue Henkel Loctite Henkel agent Henkel glue Loctite water channel Corning glue Lode glue structure glue automobile electronic glue COMS adhesive sensor adhesive sensor potting adhesive electronic potting adhesive high thermal conductivity epoxy potting adhesive high thermal conductivity epoxy potting adhesive low temperature resistant adhesive optical fiber adhesive pigtail adhesive optical communication adhesive light transmitting adhesive light blocking adhesive optocoupler adhesive Loctite agent ablestik adhesive heat conducting adhesive heat conducting adhesive glass silver adhesive conductive adhesive film insulation adhesive film DAF film blue film UV blue film, UV film, conductive adhesive, defoamer, bottom filling, defoamer, chip adhesive, chip adhesive, chip adhesive, insulating adhesive, CSP, bottom filling, die adhesive, die adhesive, conductive adhesive, conductive adhesive, film 5020, film 506, film JM7000, conductive adhesive, 84-1, conductive adhesive Ablestik conductive adhesive Henkel conductive adhesive Letai conductive adhesive Lot potting adhesive Letai film chip capping machine Glue defoamer Airtightness detection Shear force detection Chip tension test Chip ceramic packaging Chip metal packaging Wafer passivation equipment Wafer etcher TSV Wafer deposition 3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

Electronic coating UV curing material Wafer scribing protection Liquid crystal circle Temporary bonding Thinning conductive silver glue Sintering silver nano silver channel Corning COB glue red glue SMT red glue Aviation aerospace glue High temperature resistant potting glue Bond alloy wire insulation coating Bond alloy wire defoaming machine Parallel sealing machine Gluing machine KS Splitter SPT Chopper Chopper Ceramic Chopper Rodham Road Corning Dow X-RAY FIB FBI Musashi Dispensing Machine Nuoxin Dispensing Machine Potting Machine Failure Analysis Fast Packaging Ceramic Shell Package COB Package Chip Bonding Package Cleaning Liquid Crystal Circle Cleaning Solution Silicon Wafer Cleaning Solution Sapphire Cutting Solution Ceramic Scribe Cleaning Solution Chip Adhesive IC Adhesive IC Conductive Adhesive Chip Conductive Adhesive IC insulation glue Henkel Loctite Henkel agent Henkel glue Loctite water channel Corning glue Lode glue structure glue automobile electronic glue COMS adhesive sensor adhesive sensor potting adhesive electronic potting adhesive high thermal conductivity epoxy potting adhesive high thermal conductivity epoxy potting adhesive low temperature resistant adhesive optical fiber adhesive pigtail adhesive optical communication adhesive light transmitting adhesive light blocking adhesive optocoupler adhesive Loctite agent ablestik adhesive heat conducting adhesive heat conducting adhesive glass silver adhesive conductive adhesive film insulation adhesive film DAF film blue film UV blue film, UV film, conductive adhesive, defoamer, bottom filling, defoamer, chip adhesive, chip adhesive, chip adhesive, insulating adhesive, CSP, bottom filling, die adhesive, die adhesive, conductive adhesive, conductive adhesive, film 5020, film 506, film JM7000, conductive adhesive, 84-1, conductive adhesive Ablestik conductive adhesive Henkel conductive adhesive Letai conductive adhesive Lot potting adhesive Letai film chip capping machine Glue defoamer Airtightness detection Shear force detection Chip tension test Chip ceramic packaging Chip metal packaging Wafer passivation equipment Wafer etcher TSV Wafer deposition 3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

Electronic coating UV curing material Wafer scribing protection Liquid crystal circle Temporary bonding Thinning conductive silver glue Sintering silver nano silver channel Corning COB glue red glue SMT red glue Aviation aerospace glue High temperature resistant potting glue Bond alloy wire insulation coating Bond alloy wire defoaming machine Parallel sealing machine Gluing machine KS Splitter SPT Chopper Chopper Ceramic Chopper Rodham Road Corning Dow X-RAY FIB FBI Musashi Dispensing Machine Nuoxin Dispensing Machine Potting Machine Failure Analysis Fast Packaging Ceramic Shell Package COB Package Chip Bonding Package Cleaning Liquid Crystal Circle Cleaning Solution Silicon Wafer Cleaning Solution Sapphire Cutting Solution Ceramic Scribe Cleaning Solution Chip Adhesive IC Adhesive IC Conductive Adhesive Chip Conductive Adhesive IC insulation glue Henkel Loctite Henkel agent Henkel glue Loctite water channel Corning glue Lode glue structure glue automobile electronic glue COMS adhesive sensor adhesive sensor potting adhesive electronic potting adhesive high thermal conductivity epoxy potting adhesive high thermal conductivity epoxy potting adhesive low temperature resistant adhesive optical fiber adhesive pigtail adhesive optical communication adhesive light transmitting adhesive light blocking adhesive optocoupler adhesive Loctite agent ablestik adhesive heat conducting adhesive heat conducting adhesive glass silver adhesive conductive adhesive film insulation adhesive film DAF film blue film UV blue film, UV film, conductive adhesive, defoamer, bottom filling, defoamer, chip adhesive, chip adhesive, chip adhesive, insulating adhesive, CSP, bottom filling, die adhesive, die adhesive, conductive adhesive, conductive adhesive, film 5020, film 506, film JM7000, conductive adhesive, 84-1, conductive adhesive Ablestik conductive adhesive Henkel conductive adhesive Letai conductive adhesive Lot potting adhesive Letai film chip capping machine Glue defoamer Airtightness detection Shear force detection Chip tension test Chip ceramic packaging Chip metal packaging Wafer passivation equipment Wafer etcher TSV Wafer deposition 3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

Electronic coating UV curing material Wafer scribing protection Liquid crystal circle Temporary bonding Thinning conductive silver glue Sintering silver nano silver channel Corning COB glue red glue SMT red glue Aviation aerospace glue High temperature resistant potting glue Bond alloy wire insulation coating Bond alloy wire defoaming machine Parallel sealing machine Gluing machine KS Splitter SPT cleaver ceramic cleaver Rodham Road Corning Dow X-RAY FIB FBI Musashi Dispensing Machine Nuoxin Dispensing Machine Potting Machine Failure Analysis Fast Packaging Ceramic Shell Package COB Package Chip Bonding Package Cleaning Liquid Crystal Circle Cleaning Solution Silicon Wafer Cleaning Solution Sapphire Cutting Solution Ceramic Scribe Cleaning Solution Chip Adhesive IC Adhesive IC Conductive Adhesive Chip Conductive Adhesive IC insulation glue Henkel Loctite Henkel agent Henkel glue Loctite water channel Corning glue Lode glue structure glue automobile electronic glue COMS adhesive sensor adhesive sensor potting adhesive electronic potting adhesive high thermal conductivity epoxy potting adhesive high thermal conductivity epoxy potting adhesive low temperature resistant adhesive optical fiber adhesive pigtail adhesive optical communication adhesive light transmitting adhesive light blocking adhesive optocoupler adhesive Loctite agent ablestik adhesive heat conducting adhesive heat conducting adhesive glass silver adhesive conductive adhesive film insulation adhesive film DAF film blue film UV blue film, UV film, conductive adhesive, defoamer, bottom filling, defoamer, chip adhesive, chip adhesive, chip adhesive, insulating adhesive, CSP, bottom filling, die adhesive, die adhesive, conductive adhesive, conductive adhesive, film 5020, film 506, film JM7000, conductive adhesive, 84-1, conductive adhesive Ablestik conductive adhesive Henkel conductive adhesive Letai conductive adhesive Lot potting adhesive Letai film chip capping machine Glue defoamer Airtightness detection Shear force detection Chip tension test Ceramic packaging Chip Metal packaging Wafer passivation equipment Wafer etcher TSV Wafer deposition

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

b、 Scope of application

This resin can be used to replace Scotchcast ™# 241 is used in situations where better mechanical strength, tensile strength, thermal shock and thermal conductivity are required. Applications include filling and sealing of coils, transformers, motors and other power electronic components.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

c、 Usage information

(1) Mix

First mix the two components separately and heat them to 60 ℃ to facilitate mixing. Weigh the two components in the correct proportion (within 2% error) and mix them. Mix well until the color is completely uniform, or until the mixture is completely uniform.

(2) Degassing

In order to remove the gas generated during mixing, air can be pumped under the pressure of 5-10mmHg for 5-15 minutes. Heating to 60 ℃ will help degassing. The vessel wall height shall be 4 times the height of liquid resin to accommodate foam.

(3) Filling and injection

Pour warm resin into the mould preheated to 100 ℃. If the mold is not used, the preheated components can be immersed in the resin. Heat the resin and mold to aid injection. For large filling, air can be pumped under the pressure of 5mmHg for 5-15 minutes, or the mold can be opened after filling and maintaining for several minutes under vacuum.

(4) Curing

If small stress and large seismic resistance are considered, it is recommended to use the curing procedure at a lower temperature. From room temperature to curing temperature, it is recommended to give a heating time.

Xiyuan Technology Electronic Materials:

Potting glue: Lodhenhan High Road Corning Dow DuPont, etc. It is widely used in electronic power supply thick film circuit, automobile electronic semiconductor packaging and other industries.

ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive

LOCTITE ABLESTIK 104, Epoxy resin, components

LOCTITE ® ABLESTIK 104 adhesive is designed for applications requiring temperature exposure. This adhesive can withstand continuous exposure temperatures up to 230 º C. It can also withstand short-term exposure temperatures up to 280 º C.

Chemical resistance of

Non-conductive

High shear strength

YSOL STYCAST 2561/CAT 11

LOCTITE STYCAST 2651MM/CATALYST 23LV

LOCTITE STYCAST 2651MM/CATALYST 9

LOCTITE STYCAST 2850FT/CAT 11

LOCTITE STYCAST 2850FT/CAT 23 LV

LOCTITE STYCAST 2850KT/CATALYST 9

LOCTITE STYCAST 2850MT/CATALYST 24LV

Loctite STYCAST 50500D

Loctite STYCAST A312

Loctite STYCAST E1070

Loctite STYCAST E1847

LOCTITE STYCAST EFF15 SYNTACTIC FOAM POWDER3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

b、 Scope of application

This resin can be used to replace Scotchcast ™# 241 is used in situations where better mechanical strength, tensile strength, thermal shock and thermal conductivity are required. Applications include filling and sealing of coils, transformers, motors and other power electronic components.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

c、 Usage information

(1) Mix

First mix the two components separately and heat them to 60 ℃ to facilitate mixing. Weigh the two components in the correct proportion (within 2% error) and mix them. Mix well until the color is completely uniform, or until the mixture is completely uniform.

(2) Degassing

In order to remove the gas generated during mixing, air can be pumped under the pressure of 5-10mmHg for 5-15 minutes. Heating to 60 ℃ will help degassing. The vessel wall height shall be 4 times the height of liquid resin to accommodate foam.

(3) Filling and injection

Pour warm resin into the mould preheated to 100 ℃. If the mold is not used, the preheated components can be immersed in the resin. Heat the resin and mold to aid injection. For large filling, air can be pumped under the pressure of 5mmHg for 5-15 minutes, or the mold can be opened after filling and maintaining for several minutes under vacuum.

(4) Curing

If small stress and large seismic resistance are considered, it is recommended to use the curing procedure at a lower temperature. From room temperature to curing temperature, it is recommended to give a heating time.

Xiyuan Technology Electronic Materials:

Potting glue: Lodhenhan High Road Corning Dow DuPont, etc. It is widely used in electronic power supply thick film circuit, automobile electronic semiconductor packaging and other industries.

ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive

LOCTITE ABLESTIK 104, Epoxy resin, components

LOCTITE ® ABLESTIK 104 adhesive is designed for applications requiring temperature exposure. This adhesive can withstand continuous exposure temperatures up to 230 º C. It can also withstand short-term exposure temperatures up to 280 º C.

Chemical resistance of

Non-conductive

High shear strength

YSOL STYCAST 2561/CAT 11

LOCTITE STYCAST 2651MM/CATALYST 23LV

LOCTITE STYCAST 2651MM/CATALYST 9

LOCTITE STYCAST 2850FT/CAT 11

LOCTITE STYCAST 2850FT/CAT 23 LV

LOCTITE STYCAST 2850KT/CATALYST 9

LOCTITE STYCAST 2850MT/CATALYST 24LV

Loctite STYCAST 50500D

Loctite STYCAST A312

Loctite STYCAST E1070

Loctite STYCAST E1847

LOCTITE STYCAST EFF15 SYNTACTIC FOAM POWDER3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

3MScotchcast ™# 281 Electrical insulation resin

Specification: Component A: 7.2LB (3.2KG) Component B: 10.8LB (4.8KG)

a、 characteristic

3M ™ Scotchcast ™ 281 electrical insulation resin is characterized by high temperature resistance, electrical stability and flexibility, even after a long period of thermal aging. It can be cured at low temperature. In order to obtain good performance, it is recommended to select a higher temperature curing procedure.

b、 Scope of application

This resin can be used to replace Scotchcast ™# 241 is used in situations where better mechanical strength, tensile strength, thermal shock and thermal conductivity are required. Applications include filling and sealing of coils, transformers, motors and other power electronic components.

·Temperature class 155 ℃ · low temperature solid · high thermal conductivity

c、 Usage information

(1) Mix

First mix the two components separately and heat them to 60 ℃ to facilitate mixing. Weigh the two components in the correct proportion (within 2% error) and mix them. Mix well until the color is completely uniform, or until the mixture is completely uniform.

(2) Degassing

In order to remove the gas generated during mixing, air can be pumped under the pressure of 5-10mmHg for 5-15 minutes. Heating to 60 ℃ will help degassing. The vessel wall height shall be 4 times the height of liquid resin to accommodate foam.

(3) Filling and injection

Pour warm resin into the mould preheated to 100 ℃. If the mold is not used, the preheated components can be immersed in the resin. Heat the resin and mold to aid injection. For large filling, air can be pumped under the pressure of 5mmHg for 5-15 minutes, or the mold can be opened after filling and maintaining for several minutes under vacuum.

(4) Curing

If small stress and large seismic resistance are considered, it is recommended to use the curing procedure at a lower temperature. From room temperature to curing temperature, it is recommended to give a heating time.

Xiyuan Technology Electronic Materials:

Potting glue: Lodhenhan High Road Corning Dow DuPont, etc. It is widely used in electronic power supply thick film circuit, automobile electronic semiconductor packaging and other industries.

ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive ABLESTIK 104 adhesive Epoxy resin adhesive two-component adhesive High temperature adhesive

LOCTITE ABLESTIK 104, Epoxy resin, components

LOCTITE ® ABLESTIK 104 adhesive is designed for applications requiring temperature exposure. This adhesive can withstand continuous exposure temperatures up to 230 º C. It can also withstand short-term exposure temperatures up to 280 º C.

Chemical resistance of

Non-conductive

High shear strength

YSOL STYCAST 2561/CAT 11

LOCTITE STYCAST 2651MM/CATALYST 23LV

LOCTITE STYCAST 2651MM/CATALYST 9

LOCTITE STYCAST 2850FT/CAT 11

LOCTITE STYCAST 2850FT/CAT 23 LV

LOCTITE STYCAST 2850KT/CATALYST 9

LOCTITE STYCAST 2850MT/CATALYST 24LV

Loctite STYCAST 50500D

Loctite STYCAST A312

Loctite STYCAST E1070

Loctite STYCAST E1847

LOCTITE STYCAST EFF15 SYNTACTIC FOAM POWDER