What is the construction process of epoxy floor paint?

As we all know, the role of primer is very important in construction. Generally, if the primer is not well done, the quality of the floor will be greatly reduced, and the epoxy floor will blister and fall off. Here we will introduce the construction process of epoxy floor paint and the precautions for construction, so that we can choose better.

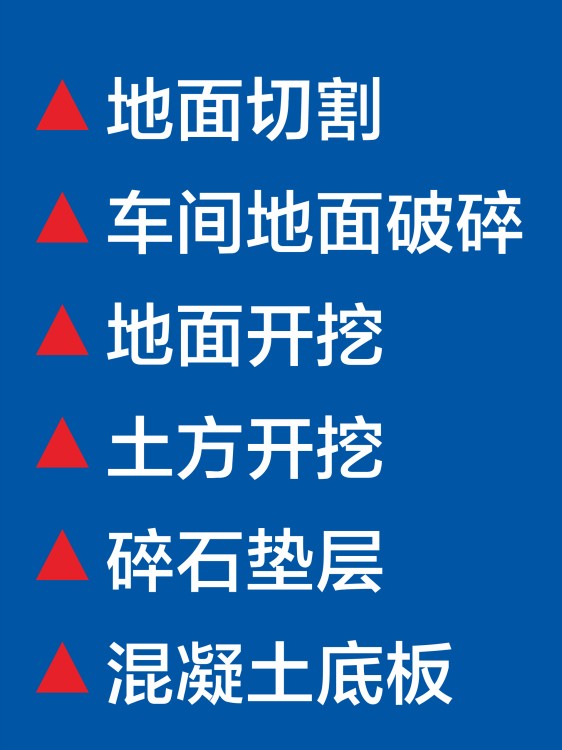

Construction process of epoxy floor paint

1. Plain location:

(1) The foundation plain ground shall be subject to the cement powder smooth surface or the millstone ground;

(2) The plain land shall be cured for more than 28 days, and the moisture content shall be less than 8% before construction. If the plain land is uneven or empty, it shall be removed;

(3) Use epoxy mortar to fill the ground;

(4) The oil stain of plain land shall be thoroughly cleaned;

(5) Keep the construction site dry and clean before construction.

2. Primer:

(1) Before construction, keep clean. If there are sundries, remove them. Mix the main agent and hardener according to the correct proportion and fully mix them;

(2) The proper viscosity shall be adjusted according to the ground conditions, and the construction of materials shall be completed within 4 hours;

(3) The curing and hardening time of the primer is more than 8 hours.

3. Midcoat

(1) Before construction, keep clean. If there are sundries adhering, remove them. Mix the main agent and hardener according to the correct proportion and fully mix them;

(2) Add proper amount of mixed resin into quartz sand;

(3) Apply the material evenly with a trowel;

(4) The construction of mixed materials shall be completed within 30 minutes;

(5) The construction handover shall be completed;

(6) The curing and hardening time of the intermediate coating is more than 8 hours.

4. Batch soil layer

(1) Mix the main agent and hardener according to the correct proportion and fully stir;

(2) Use a batch knife to evenly coat the material;

(3) The construction of mixed materials shall be completed within 30 minutes;

(4) The curing and hardening time of soil is more than 8 hours;

(5) According to the actual needs, the number of construction passes shall be flat and free of holes, knife marks and sanding marks.

5. Topcoat

(1) Keep clean before construction, and remove sundries if any;

(2) Stir the main agent evenly before use;

(3) Mix the main agent and hardener according to the correct proportion and fully stir;

(4) Use roller or trowel to evenly coat and mix the materials, and the construction shall be completed within 30 minutes;

(5) The construction handover shall be completed;

(6) After the construction is completed, people can get on 24 hours later, and heavy pressure can be carried out 7 days later (subject to 250C, and the opening time should be appropriate at low temperature).

Epoxy floor industrial flooring has the characteristics of seamless, flat, smooth, clean, convenient, overall tough, wear-resistant, economical and practical. It is suitable for chemical, textile, precision instruments, machinery manufacturing and other production workshops, and plays a major role in the working environment of anti-static, weight resistant, wear-resistant land manufacturing industry. What are the requirements of general epoxy floor paint project on concrete substrate.

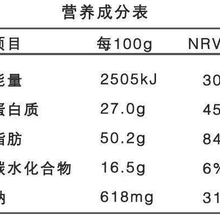

The concrete of the epoxy floor paint project shall be flat and dense, with a strength of C20. Otherwise, the pressure resistance, impact resistance and durability of the epoxy floor coating will be affected. The drop within 2m of the ground flatness shall not exceed 2mm; Otherwise, only increase the thickness of epoxy floor to make up; If the concrete ground is at the bottom and the ground water level is at the plane, waterproof work should be done to prevent the rising water vapor of ground water from jacking up the epoxy floor paint, which will lead to blistering and shelling.

When repairing the damaged concrete surface, cement mortar can be used for filling and design according to the above flatness requirements; During the construction of epoxy floor paint project, resin mortar or polymer cement sand can be used for leveling. If there are cracks on the concrete surface, the cracks can be reserved during the construction of the epoxy floor, and then the elastic glue can be used to fill the cracks.

In order to ensure the smooth construction and long service life of the epoxy floor paint project, the concrete shall be treated in strict accordance with the standard, filled and patched, and the hardness shall be strengthened. After the construction of the epoxy floor paint, the phenomenon of wrinkling and peeling off shall be prevented.

Factory decoration is a complex and comprehensive project, which usually includes the decoration of factory buildings, workshops, as well as the front desk, exhibition halls, office buildings or offices and other facilities of the factory. The design of enterprise factory decoration projects involves many aspects, such as steel structure, fire safety, heating, ventilation and weak current projects. Some workshops with higher requirements, such as dust-free workshops, anti-static workshops Laboratory, etc.

For customers, the decoration of factory buildings is very important. A good and good decoration can improve the customer's corporate image, the recognition of employees, and the work efficiency of employees. Therefore, it should be better within the appropriate budget. A large decoration design company provides you with factory and enterprise factory building decoration projects including office, conference room, reception room and exhibition hall decoration. The types of clean workshop, conventional workshop and required workshop can be designed, decorated and constructed for you. I have been engaged in design and decoration for more than ten years, and have a large number of experience cases. Welcome to consult.