Curing agent, also known as hardener, curing agent or setting agent, is a kind of substance or mixture that promotes or controls curing reaction.

Resin curing is an irreversible change process of thermosetting resin through chemical reactions such as condensation, closed-loop, addition or catalysis. Curing is completed by adding curing (cross-linking) agent.

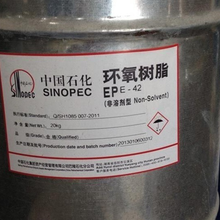

Curing agent is an additive. Curing agent shall be added whether it is used as adhesive, coating or castable, otherwise the epoxy resin cannot be cured. The variety of curing agent has great influence on the mechanical properties, heat resistance, water resistance and corrosion resistance of the cured product.

Curing temperature and heat resistance of curing agent

The curing temperature of various curing agents is different, and the heat resistance of cured products is also very different. Generally speaking, the curing agent with high curing temperature can be used to obtain the cured product with excellent heat resistance. For addition polymerized curing agent, the curing temperature and heat resistance shall be increased in the following order:

Aliphatic polyamines<alicyclic polyamines<aromatic polyamines<phenolic aldehyde<anhydride

The curing reaction is a chemical reaction, which is greatly affected by the curing temperature. The higher the temperature, the faster the reaction speed, and the shorter the gel time; The logarithm of gelation time decreases linearly with the increase of curing temperature. However, if the curing temperature is too high, the performance of the cured product will often decline, so there is an upper limit of the curing temperature; Select the temperature that makes a compromise between the curing speed and the properties of the cured product as the appropriate curing temperature. According to curing temperature, curing agents can be divided into four categories: low-temperature curing agents curing temperature below room temperature; The curing temperature of room temperature curing agent is between room temperature and 50 ℃; Medium temperature curing agent is 50~100 ℃; The curing temperature of high-temperature curing agent is above 100 ℃. There are few kinds of curing agents that belong to low temperature curing type, such as polyurethanes, polyisocyanates, etc; T-31 modified amine and YH-82 modified amine developed and put into production in China can be cured below 0 ℃. There are many kinds of room temperature curing type: aliphatic polyamines, alicyclic polyamines; Low molecular polyamide and modified aromatic amine, etc. A part of alicyclic polyamines, tertiary amines, midazoles and boron trifluoride complexes are of medium temperature curing type. The high-temperature curing agents include aromatic polyamines, acid anhydrides, resol resins, amino resins, dicyandiamide and hydrazide.

For the high-temperature curing system, the curing temperature is generally divided into two stages. The low-temperature curing is adopted before the gel. After the gel state or the state slightly higher than the gel state is reached, the high-temperature heating is used for post cure. Compared with the previous stage, the curing is pre cure.

In terms of hue, alicyclic group is shallow and basically transparent, while aliphatic group and aromatic group have significant coloring degree. In terms of viscosity, there are also great differences. The alicyclic group is only a fraction of Pa · s, while polyamide is very viscous, up to several Pa · s, and most aromatic amines are solid. The length of application period is exactly opposite to the curing property. The aliphatic group has high reactivity, while the alicyclic group, amide and aromatic group decrease in turn.

Classification by use

Curing agent can be divided into room temperature curing agent and heating curing agent according to the use. Epoxy resin generally has good performance when cured at high temperature, but coatings and adhesives used in civil construction need to be cured at room temperature due to heating difficulties; Therefore, aliphatic amines, aliphatic epoxides and polyamides are mostly used, especially the coatings and adhesives used in winter have to be used together with polyisocyanates, or polyisocyanates with foul smell are used.

As for medium temperature curing agent and high temperature curing agent, the choice should be based on the heat resistance of the object to be landed and the heat resistance, adhesion and drug resistance of the cured object. Polyamine and anhydride are selected. Because anhydride cured products have excellent electrical properties, they are widely used in electronics and electrical appliances.

The adhesive property, alkali resistance and water resistance of the cured product of aliphatic polyamine are excellent. Aromatic polyamines are also excellent in drug resistance. As the nitrogen element of amino group forms hydrogen bond with metal, it has excellent antirust effect. The higher the amine concentration, the better the antirust effect. Acid anhydride curing agent forms ester bond with epoxy resin, showing high resistance to organic acid and inorganic acid, and its electrical performance generally exceeds that of polyamine.

The variety of curing agent has a great impact on the mechanical properties, heat resistance, water resistance, corrosion resistance, etc. of the cured product. For example, curing agents such as aromatic polyamines, imidazole, and anhydride can cure heat resistant aliphatic polyamines and low molecular polyamide curing agents of epoxy resin; The water resistance of aromatic anhydride cured epoxy resin is better than that of aromatic diamine and aliphatic polyamine curing agents; The triethylenetetramine curing agent has good alkali resistance, but poor acid resistance and formaldehyde solution resistance. The resistance of epoxy resin cured by alicyclic polyamines (such as isophorone diamine) is excellent. Alkali resistance of epoxy resin cured with anhydride curing agent is better than acid resistance. Appropriate curing agent shall be selected according to different uses and performance requirements.