product name |

Urea formaldehyde resin liquid, urea formaldehyde resin powder, urea formaldehyde resin factory, urea formaldehyde resin adhesive |

Region oriented |

whole country |

Manufacturer (place of origin) |

Henan Paishengxiang |

Specifications |

liquid |

Content ≥ (%) |

eighty |

Implement quality standards |

national standard |

Supply mode |

goods in stock |

CAS |

3602-55-9 |

Brand |

E-51 |

density |

0.77kg/m3 |

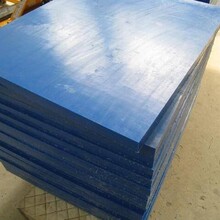

Abrasive cloth, abrasive paper, urea formaldehyde resin 963-1

Urea formaldehyde resin powder water-soluble resin powder melamine glue powder

Manufacturing of plywood, veneer, curved wood furniture, improving the solid content of liquid urea formaldehyde glue, mold casting, grinding wheel manufacturing, etc

1. Preparation of glue mixture

Before use, dissolve the powdered urea formaldehyde resin in water at a suitable temperature of 15-30 ℃. When dissolving the resin with hot water, it is important to cool the resin grease solution before adding the curing agent, otherwise the active period of the adhesive will be shortened.

2. Technical indicators

White appearance, free flowing powder

Viscosity 25 ℃ (glue: water=2:1) 2500-3500 mPa • S

PH 25 ℃ (glue: water=2:1) 7.5-8.0

Specific gravity 25 ℃ (glue: water=2:1) About 1.220g/cm3

3. The proportion (weight) of glue mixture is

Urea formaldehyde resin powder 100

Water 40-60

Appropriate amount of modifier

Appropriate amount of curing agent

4. Uses: manufacturing plywood, veneer, curved wood furniture, improving the solid content of liquid urea formaldehyde glue, mold casting, grinding wheel manufacturing, etc.

5. Storage and transportation: The resin must be sealed in its original container and strictly stored in a dry place with suitable temperature (ideal temperature 15-30 ℃). It can be stored for 12 months under such conditions. Urea formaldehyde resin powder is nonflammable.

6. Package: standard bag, net weight of each bag is 25kg.

make:

Wood preparation

The glued wood shall be even in thickness, and its surface shall be free of grease, dust and other contaminants. The wood moisture content shall be 6-13%.

Gluing amount: the gluing amount depends on the surface quality of the gluing material, and generally 150-200g/㎡. On a very smooth surface (such as MDF) or on a mask, the amount of glue can be reduced appropriately. On the contrary, on some rough surfaces, such as veneer surface, more glue is required.

Aging time: The shorter the aging time, the better. The allowable long storage time depends on the amount of glue applied, the type of wood, temperature, relative humidity and air velocity (ventilation conditions and displacement). Generally, it is carried out when the pressure is sticky with glue.

Pressure: the pressure depends on the density, surface smoothness, thickness tolerance and auxiliary installation time of the adherend.

The normal pressure is 0.5-1.6Mpa (5-16kg/cm2).

Pressurizing time: cold pressing is 6-8h, and hot pressing depends on materials and heating conditions. Materials with high density and low absorption, such as hardwood, special particleboard (water resistant), etc., need more pressure time.

Formaldehyde emission: the formaldehyde emission of the product bonded by urea formaldehyde powder depends on many factors. The important factors are: tree species, formula of glue mixture (type and quantity of modifier/curing agent), glue amount, glue speed, humidity of glued materials, distance from glue line to surface, paving time and pressure conditions. In addition, add

The modifier can effectively reduce formaldehyde emission.

Cleaning: glue mixing and coating equipment must be cleaned before and after glue placement. It is easy to do with warm water. Once cured, the adhesive is insoluble. If the glue residue and water used for cleaning are discharged into the sewer pipe, they will cause pollution, so corresponding treatment measures should be taken for them.

Safety precautions: urea formaldehyde resin powder can be operated safely. To avoid direct contact with the unhardened glue on the skin, which will affect people with skin allergies, you should wear impermeable gloves. Similarly, you should pay attention to eye protection to prevent splashing into the eyes. Wash your hands before meals and after work, and dry your skin with a paper towel after washing. Avoid inhaling dust when emptying the transport bag. In addition, the ventilation condition of good strips is very important, especially in glue mixing and coating

3、 Abrasive cloth, abrasive paper, urea formaldehyde resin 563-1

*Sandcloth, sandpaper urea formaldehyde resin 563 # - 1 product details*

This product is a kind of modified polymer adhesive, UF for short, which is synthesized by urea, formaldehyde, modifier and catalyst. The resin is abrasive cloth and abrasive paper resin, because the resin has high bonding strength; Good water resistance, oil resistance, heat resistance and water solubility, can be mixed with water in a large proportion, and has high storage stability at room temperature for more than three months; Moreover, it is cheap, moisture-proof and mold proof, and is widely used in:

(1) The substrate treatment, together with animal glue and polyvinyl alcohol, can increase the strength and reduce the shrinkage of the substrate;

(2) , production of sheet emery cloth and emery paper;

(3) Production of water resistant abrasive cloth and abrasive paper;

(4) Rolled and banded coated abrasives;

(5) , semi material abrasive cloth, abrasive paper, etc.

1、 Physical and chemical indicators:

Appearance: colorless white viscous liquid

Viscosity: 60-100 seconds

Solid content: 60-65%

Free aldehyde: less than 3

PH value: 7-8

2、 Usage:

During use, 0-0.5% of the curing agent ammonium chloride shall be added according to the temperature and the required curing time, and stirred evenly for immediate use.

3、 Storage stability:

Under normal temperature, it can be stored for three months without direct sunlight.

View all introductions