Chaonan District Roland Carbon Brush National Logistics, directly supplied by Roland Carbon Brush Manufacturer

Source: Guangzhou Huangpu Xiangtan Motor Repair Shop

Time: 2024-07-01 14:28:41

[Report]

Metal grounding carbon brush is an important part used to protect equipment from static electricity. During use, carbon brushes will gradually wear out and need to be replaced in time for normal operation of the equipment. The following describes several replacement methods for metal grounding carbon brushes: 1 Manual replacement method: This is a common replacement method and a simple method., The original carbon brush needs to be pulled out first. Then, insert the new brush into the brush holder and ensure that the brush is in full contact with the ground wire. Tighten the brush holder to ensure that the brush is firm and not loose. 2. Automatic replacement method: This is an automatic replacement method for carbon brushes, usually applicable to some equipment or equipment that is not convenient for manual replacement. The method uses a motor or a pneumatic device to automatically replace the carbon brush through a certain mechanical structure. This method is more convenient and fast, and also reduces the complexity of manual operation.

When replacing the metal grounding carbon brush, the carbon brush that meets the requirements shall be selected. Good quality carbon brushes can not only better protect equipment, but also reduce the frequency of replacing carbon brushes and reduce maintenance costs. Therefore, when replacing the metal grounding carbon brush, it is necessary to select appropriate materials to ensure the operation stability of the equipment.

On the same motor, brushes of the same model and manufacturer shall be used. Because the performance of brushes produced by different manufacturers is very different, even the performance of brushes produced by the same manufacturer at different times is also different. Therefore, for the same motor, the same model and manufacturer should be selected as far as possible, preferably the brushes produced at the same time, so as to prevent the imbalance of current distribution of parallel brushes caused by the difference in brush performance from affecting the normal operation of the motor.

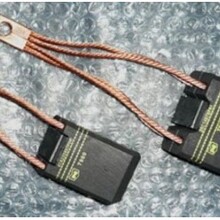

For large and medium-sized motors with special difficulty in individual commutation, braided brushes can be selected. The purpose is to improve the commutation performance by increasing the short-circuit current in the brush. For motors with difficulty in one-way rotation and commutation, combination brushes can be selected. That is to say, low resistance graphite based electrochemical graphite brush with good lubrication performance and strong film forming ability shall be selected for sliding in, and high resistivity carbon black based electrochemical graphite brush with good commutation performance shall be selected for sliding out. This not only easily forms an oxide film, but also improves the commutation performance. The carbon fiber composite brush can also be used at the sliding edge, making use of its strong arc extinguishing ability, so that the operation of the motor can achieve good results.

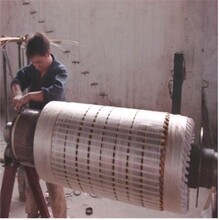

The carbon brushes and slip rings should be inspected every day. The main inspection items are: (1) The wear length of the carbon brushes should not exceed 2/3. When the wear length of the carbon brush exceeds 2/3 (that is, the top of the carbon brush is on the same plane as the top of the brush holder), replace it. (2) The carbon brush has no spark. When the carbon brush starts to spark, find out the cause and eliminate it in time. (3) The carbon brush does not deviate from the outside of the slip ring, and the edge of the carbon brush does not crack. (4) The carbon brush braid is well connected with the brush holder and the carbon brush, without heating and touching the brush holder. (5) The carbon brush shall not bounce, shake or jam in the brush holder. (6) Regularly use a DC clamp type meter to measure the current sharing of each carbon brush evenly, and use an infrared thermometer to measure whether the carbon brush is overheated. If there is any abnormality, replace it in time. (7) The spring pressure is normal without deformation and fracture. Under normal conditions, the pressure applied to each carbon brush shall be uniform and stable. The unit pressure is usually between 1.1kg and 2.5kg. The uneven pressure difference between each carbon brush shall be within 5%. (8) The distance between the brush holder and the slip ring meets the specified value. The distance between the generator brush holder and the slip ring is 2.5~3 mm, and the distance between the main excitation brush holder and the slip ring is 2~4 mm.

When the brush is worn to a certain extent, it needs to be replaced with a new one. If the brush is mixed with the old one, the current distribution may be uneven. For large units, stopping the machine to replace the brush will inevitably affect production, and you can choose not to stop the machine. We usually recommend that customers replace 20% of the brush each time (that is, 20% of each brush rod of each motor), with an interval of 1-2 weeks. After running in, gradually replace the rest of the brushes to ensure the normal and continuous operation of the unit.

Label: Chaonan Roland carbon brush, directly supplied by Roland carbon brush manufacturer, Chaonan Roland carbon brush, quotation of Roland carbon brush