Chang'an PM35 mold breathable steel exhaust steel

Chang'an PM35 mold breathable steel exhaust steel

Business Scope

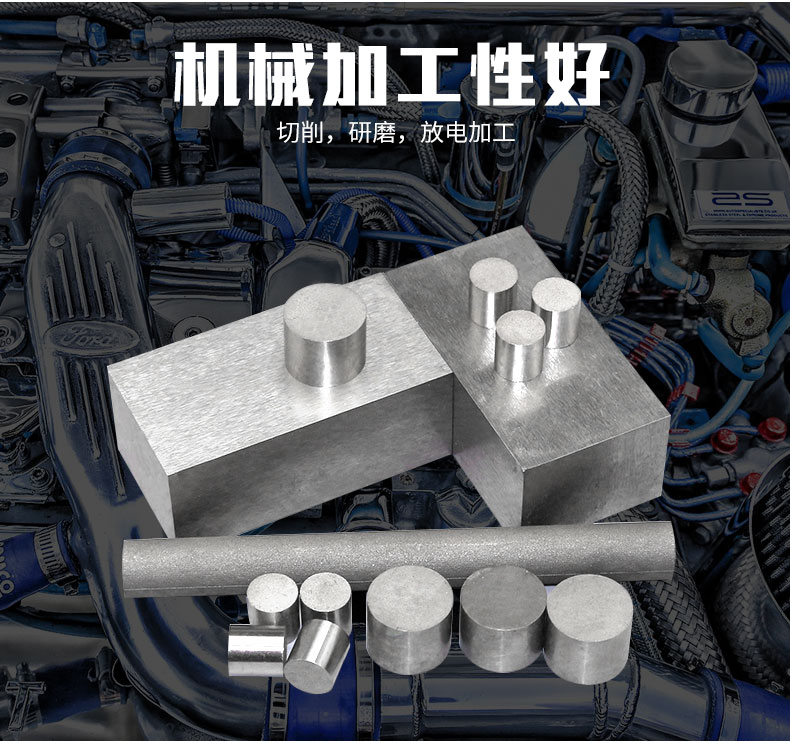

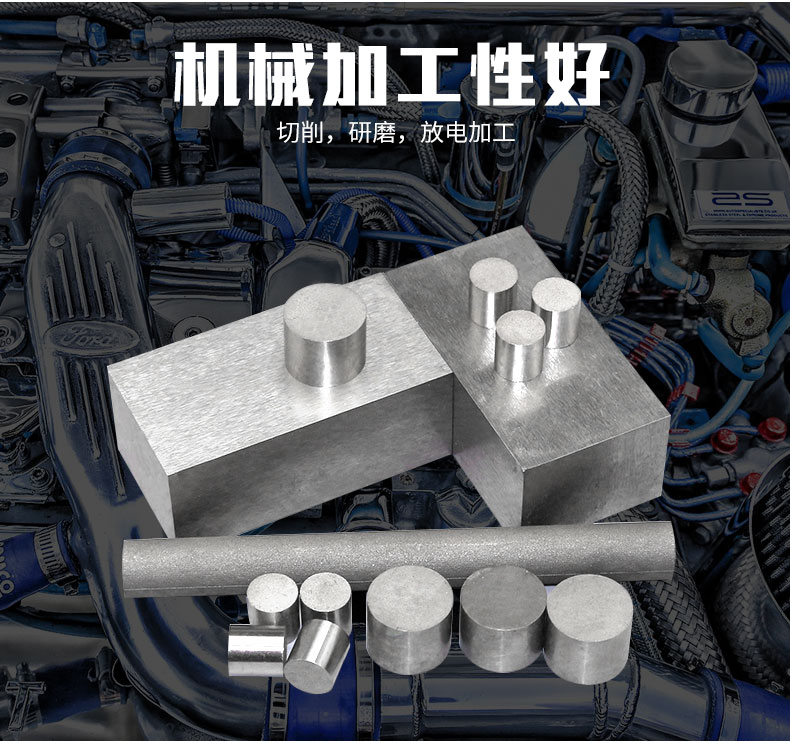

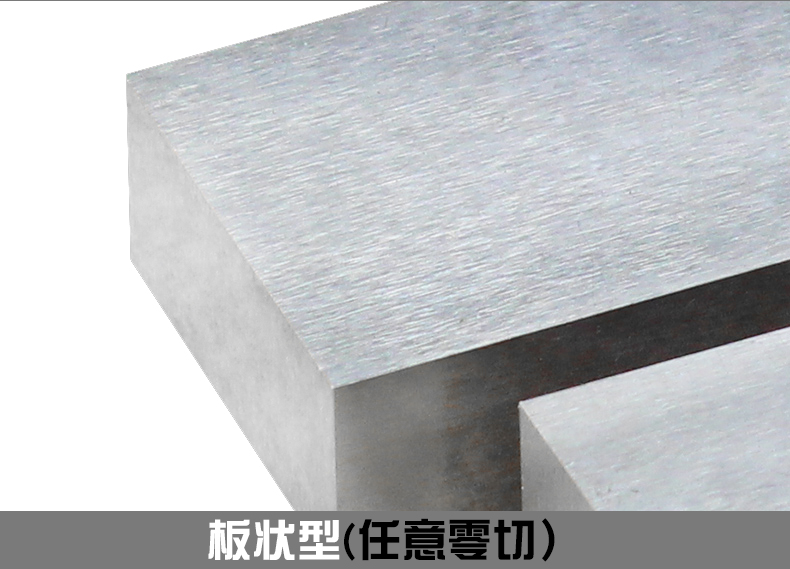

● Die steel, Breathable steel , Light guide plate mold have Steel, Round steel

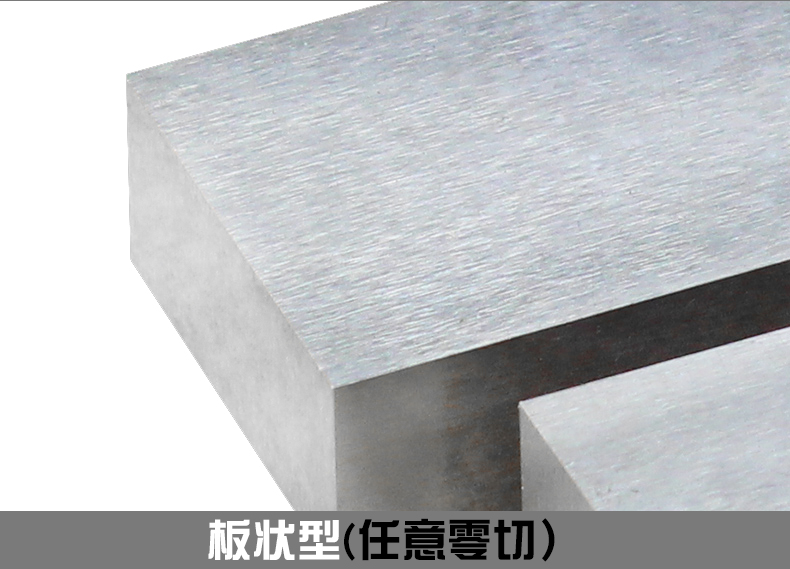

Permeable steel is a special sintered powder steel, which is sintered and refined from numerous small steel ball powders. density 6.3-6.5 Left and right, the proportion of pores in the total volume of steel 20-30% 。 After grinding or heavy cutting , It will block micropores, so it should be reserved first zero point one ~ 0.2mm Allowance. Then soft processing such as wire cutting, electric pulse and laser with slight force on the workpiece (diameter shall be used for wire cutting 0.25mm Or above copper wire processing, if small copper wire is used one point five Times the processing speed) to dredge the micropores; The side and bottom of the insert surface shall also be carried out. It is not allowed to weld or make large area integral structure. Cnc The oil-water must be blown off immediately after the water-soluble cutting fluid. Do not knock with hard objects.

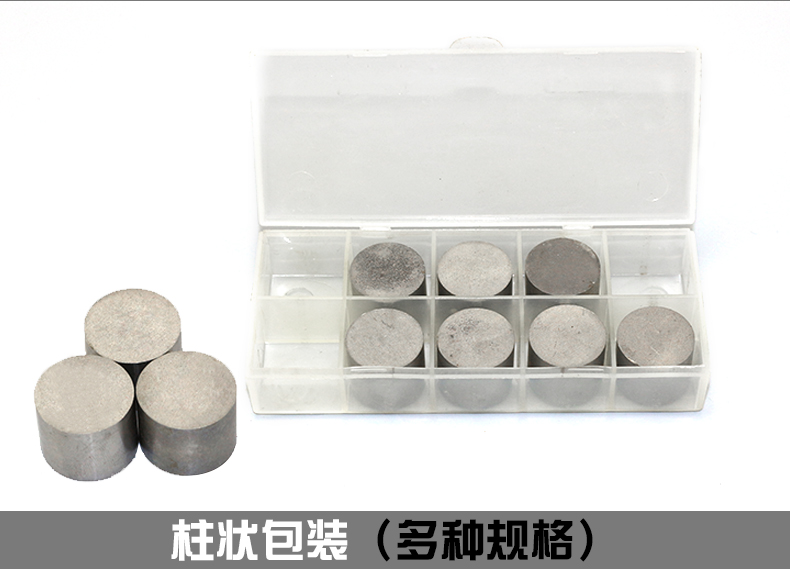

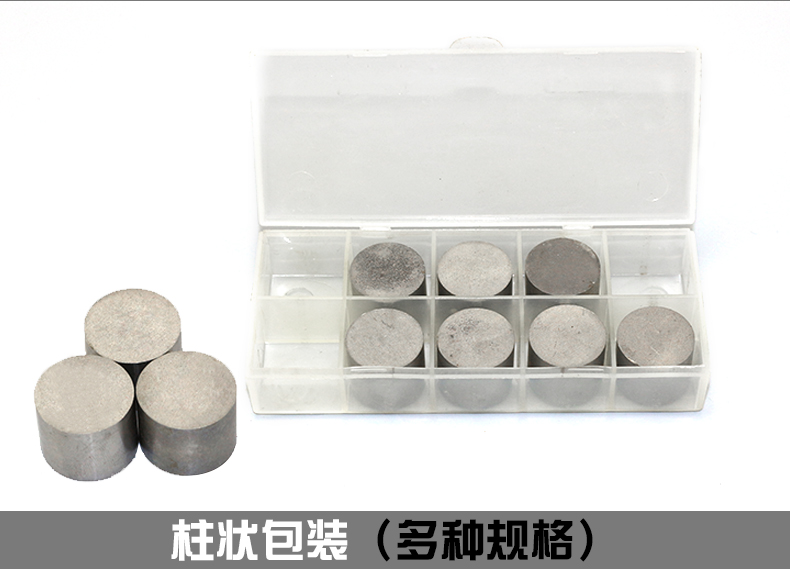

There are three kinds of apertures, PM-35 : PM-35-7(7 Micropore ) , PM-35-25(25 Micropore ) , PM-35-35 (35 Micropore ) 。

Use when cutting M Class A superhard alloy tool is not suitable for injection mold of thermosetting plastics and rubber, and is not suitable for mirror polishing mold SILICONE The anti rust agent oil dirt must be removed before use.

Use when cutting M Class A superhard alloy tool is not suitable for injection mold of thermosetting plastics and rubber, and is not suitable for mirror polishing mold SILICONE The anti rust agent oil dirt must be removed before use.

After processing, it needs to be soaked in acetone and cleaned with ultrasonic wave, or the pores will be blocked.

Methods for unblocking air holes:( one ) four hundred and twenty No. 1 sandpaper , Then one thousand and two hundred No. 1 abrasive paper polishing. ( two )Soak with acetone after processing, ultrasonic cleaning and air gun blowing. (3) Heat to 100-150 ℃, and then blow with compressed air.

Methods for unblocking air holes:( one ) four hundred and twenty No. 1 sandpaper , Then one thousand and two hundred No. 1 abrasive paper polishing. ( two )Soak with acetone after processing, ultrasonic cleaning and air gun blowing. (3) Heat to 100-150 ℃, and then blow with compressed air.

Rules for use:

Rules for use:

one . After grinding or any heavy cutting , Micropores may be blocked. Soft cutting processing such as wire cutting, electric pulse and laser shall be used (soft cutting refers to the cutting mode that has a slight force on the workpiece but does not change the surface structure) , The processing speed should be slightly increased during online cutting , Too slow may produce arc in the micropore , Bad for molybdenum wire. Hard cutting can be used when machining allowance is large , But it must be reserved zero point one ~ 0.2mm The allowance is completed by soft machining. When air permeability is restored on the surface of the restored breathable steel , There are many ways to deal with it :1. The best treatment is to use the electrical discharge machining method , The mirror surface is processed to remove the iron filings blocking the air vent. two Hand grinding , use 420 No. 1 abrasive paper grinding , Then 1200 It shall be completed after polishing with No. 1 abrasive paper. three The treatment process is not only carried out on the front of the inner module of breathable steel , The inner surface of the insert must also be treated in the same way , Only then can the air permeability of the insert be restored. four An exhaust hole is arranged on the mold of the connected breathable steel insert. example : stay 30*30mm2 Of PM-35 One is set behind the breathable steel insert ? 10mm Left and right air vents and service air inlet connections. Its function is: one Guide the gas out of the mold .2. High pressure air shall be connected regularly , Remove dirt , So as to keep the pores of breathable steel unblocked.

two . PM-35 When breathable steel is used as insert , Please try to keep with the mold base 1/10 Scale size of , I.e PM-35 The volume of breathable steel is one Or above , The volume of the mold base is 10 。 PM-35 The thickness of breathable steel insert shall be kept within 30mm-50mm between. PM-35 The air permeability of breathable steel insert will be affected by its thickness. The thicker the material is , The lower the permeability , But be careful , If the insert is too thin , It may not withstand the high injection pressure. The position, size and quantity shall be reasonably arranged on the mold. It is recommended to use it on the moving die. The air permeability of breathable steel is proportional to the surface area , The larger the surface area , The more breathable. Higher height , The weaker the air permeability , The diameter and thickness shall be reasonably selected.

three . After restoring the air permeability treatment process , Remove the oil dirt on the surface , The interior of the material is also kept clean , Clean the oil dirt , According to: (1 dry ,2 ultrasonic cleaning ,3 dry ) The process of. Pay attention to the coolant flowing into the material body during processing , The micropore will be blocked for a long time , It shall be cleaned quickly after processing.

four . Other methods for removing oil stain one Take out from the mold PM-35 Breathable steel insert heated to 100℃-150℃, Let the oil evaporate , Then flush the surface with compressed air. two If the insert is connected to the mold base , Flush with compressed air through the exhaust port of the mold , Remove the oil dirt on the surface.

five . Cutting, grinding WIRE CUT Cutting oil used in , Try to use oil type I , If water-soluble cutting oil is used , Use the above methods to remove oil contamination immediately after processing , Remove the moisture from the steel as soon as possible.

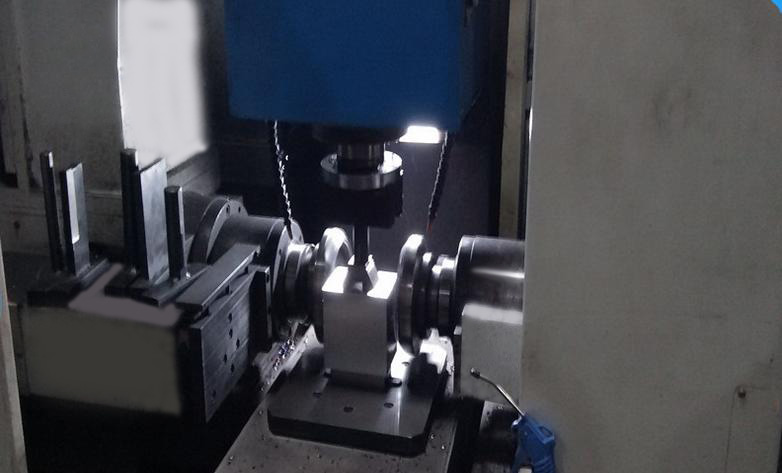

Our factory is located in Chang'an Town, Dongguan, a beautiful national famous mould town, adjacent to Shenzhen City in the east, the Pearl River estuary in the south, and at the foot of the beautiful Lotus Mountain. Dongguan Baisheng Mould Steel is a member enterprise of Dongguan Baisheng Mould Technology Co., Ltd., formerly founded in two thousand and eight The Chang'an Xintai provincial mold polishing shop in, relying on the customer's solution to the problem of mold polishing material grain, acts as an agent for the distribution of mold steel and copper materials from major domestic steel mills and international manufacturers such as Germany, Sweden, Japan and the United States. Our factory has large sawing machine, large water mill, gantry milling and other processing equipment, which can directly provide customers with raw materials, polished boards and precision boards; The company has established CNC Processing factory can process parts according to customer drawings.

One corner of the warehouse:

Material certificate of the company:

Testing equipment of the company:

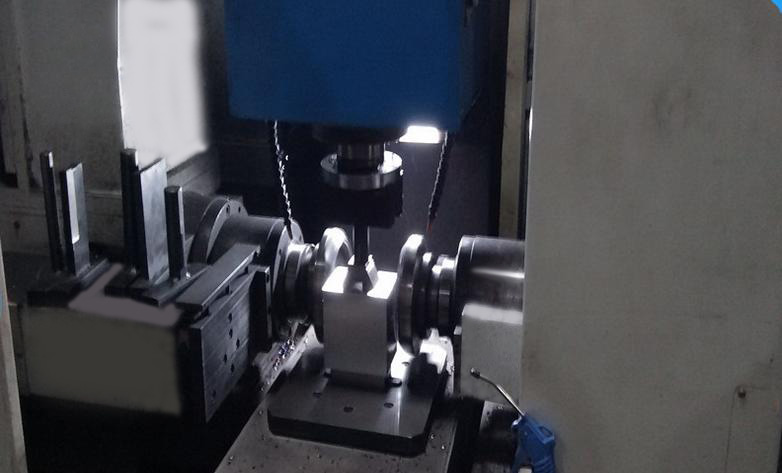

Processing equipment of the company:

Large stroke large water grinder

Fujitai band sawing machine

Double end side milling machine

Our Mould Manufacturing Business Department:

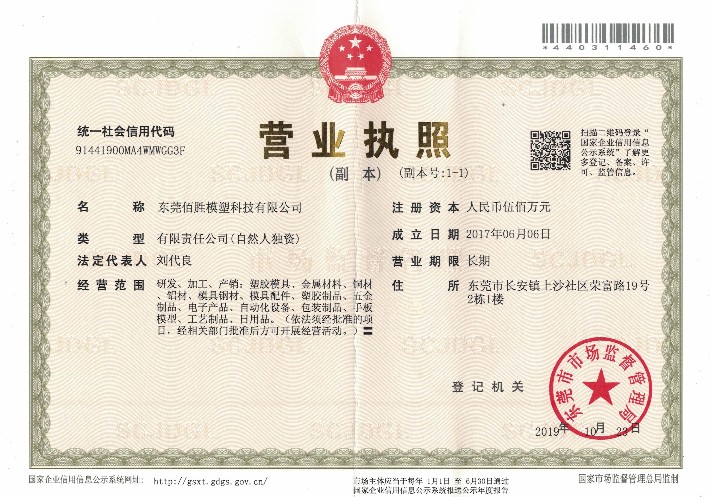

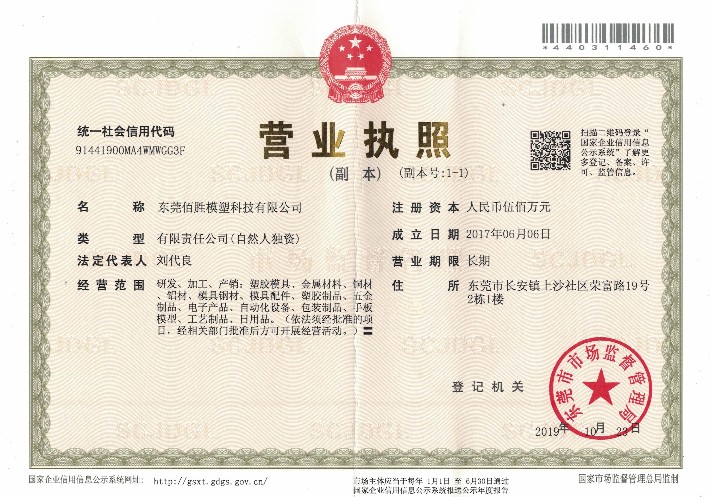

Company Certificate:

Company video:

Dongguan Baisheng Moulding Technology is located in Dongguan City, Guangdong Province, known as the world's factory, and is located in the beautiful national famous mechanical mold town - Chang'an Town is adjacent to Shenzhen in the east and Pearl River estuary in the south, at the foot of the beautiful Lotus Mountain. It is a mold manufacturing and metal material production and marketing service provider in Asia. The company has a core team composed of a group of R&D talents and technical consultants. After more than ten years of enterprising and diversified operation, it has developed into an enterprise integrating mold manufacturing, production and marketing of mold steel, copper, and processing. Registered capital of the company five hundred Ten thousand yuan, with general taxpayer qualification, has a certain reputation in the industry. The company adheres to “ A man of conscience will win if he is strong ” Business philosophy “ Be China five hundred Strong product provider ” For the enterprise vision, we are willing to join hands with customers to enter a more brilliant tomorrow ……