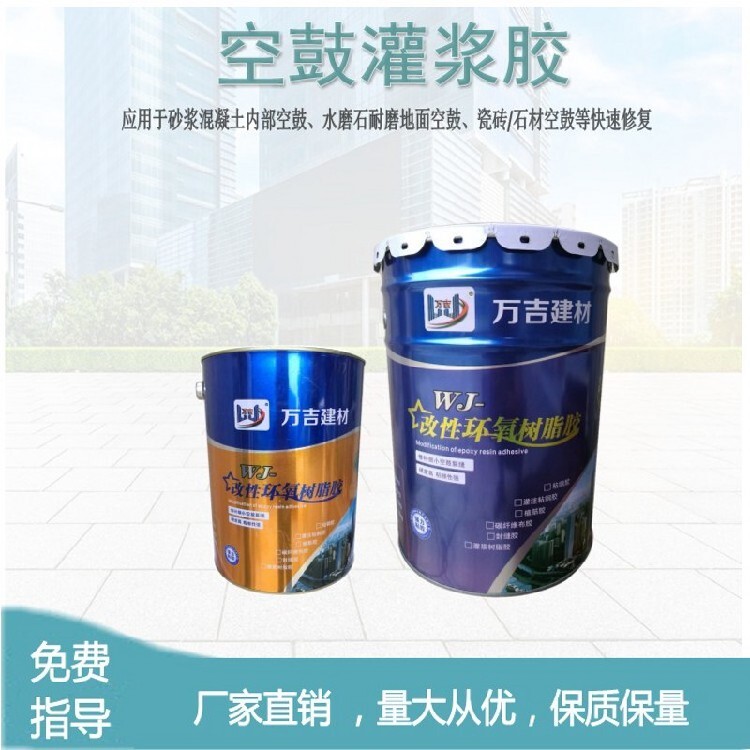

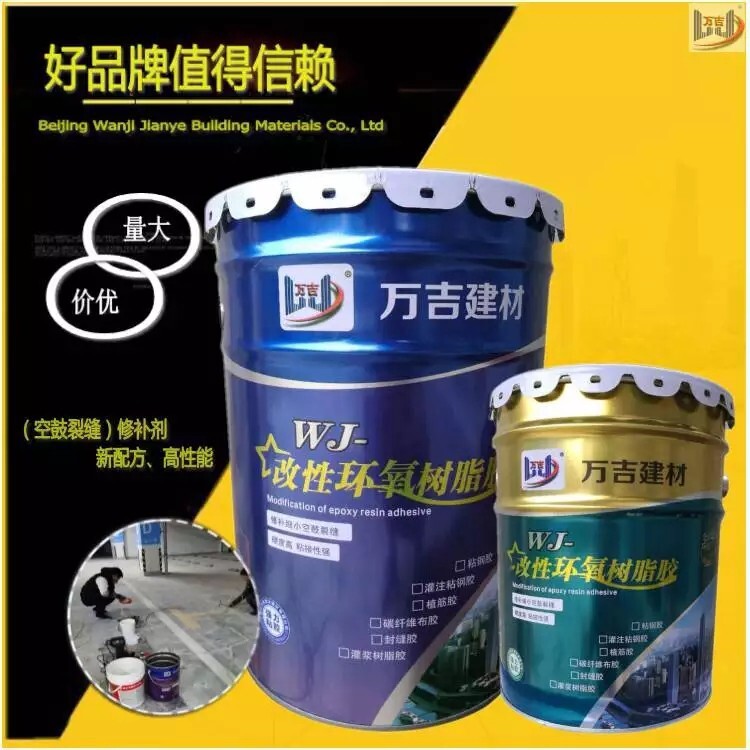

Repair principle: WJ-401 Introduction to Micropore Grouting Technology Micropore grouting technology is a new technology for chemical grouting against hollowing of concrete secondary pouring surface, stone hollowing, etc., which is developed by Beijing Wanji Construction Co., Ltd. Based on the principle of high and low pressure injection, WJ-401 grouting resin, a low viscosity and high strength hollow drum repair material, is injected into the hollow drum through the grouting tool pressure grouting pump or grouting machine to automatically fill, bond and repair the hollow parts of concrete, and improve the durability and integrity of the concrete surface structure.

WJ-401 hollow crack repair adhesive Product features:

1. Low viscosity, high fluidity: it can penetrate into the tiny empty drum position to achieve the full filling effect;

2. No shrinkage and expansion: after pouring, the empty drum position can be fully filled;

3. High bonding strength, two-way penetration: firmly bond the base course and surface course;

4. Green environmental protection. This material is a green environmental protection product and will not pollute the air quality and the base layer. It is suitable for indoor environment.

5. Good durability: good deformation resistance, and the durability is synchronized with the concrete.

Company introduction: Beijing Wanji Jianye Building Materials Co., Ltd. (hereinafter referred to as Wanji Jianye) is an enterprise integrating scientific research, production, sales, operation and management. We focus on the R&D, production and sales of products in structural reinforcement, maintenance and transformation and crack treatment. Main products of the company: hollowing crack repair materials, high-strength non shrinkage grouting materials, concrete interface agents (new and old concrete connection interface agents), concrete sanding and dusting treatment agents, high polymer mastic, epoxy resin interface adhesive, epoxy resin mastic, ECM epoxy repair mortar, polymer mortar series, concrete crack hollowing repair materials, 108 building concentrated adhesive powder, Class A building structure series and other products have been sold to all provinces, cities and autonomous regions throughout the country, and are widely used in major projects of equipment installation, structure reinforcement, building maintenance in high-speed railway, metallurgy, petrochemical, power, coal, machinery, construction, light industry, marine engineering, road and bridge, environmental protection, municipal administration and other fields. Its quality and good service have been praised by customers.

Hollow and microporous grouting treatment technology: construction steps:

1. Statistics of hollowing parts: before construction, make a detailed * * * statistics of hollowing on the ground and wall, and use a small hammer to mark the hollowing parts on the drawings.

2. Borehole positioning: the layout of the hole location is very critical, and the selection of the hole location has a great impact on the grouting effect. The experienced construction personnel should design and position the hole location of each hollow hole.

3. Permeability test: before grouting with high-pressure grouting machine, permeability test shall be carried out on the borehole to ensure the permeability of the borehole and lay the foundation for smooth grouting.

4. Crack sealing and installation of grouting nozzle: in order to ensure that the grout does not flow out when grouting is pressurized, the crack shall be closed and the grouting nozzle shall be installed before grouting.

5. Pressurized grouting: use the high-pressure grouting machine or low-pressure grouting machine to evenly press WJ-401 hollowing repair material into the grouting hole.

6. Check the plumpness: while grouting, knock with a small hammer to check and judge the flow direction and plumpness of grout.

7. Cleaning and repair: J-401 hollowing repair material has high strength after curing, which is difficult to clean. During grouting, the spilled material should be cleaned at any time, and can be wiped with a rag dipped in ethanol. For the treatment of stones and face tiles, in order to bond hollow stones and face tiles to the wall, after the grouting effect is determined, it can be loaded, supported or anchored with stainless steel nails. After the resin is solidified, the grouting nozzle can be removed and the grouting hole can be repaired.

8. Curing: After the hollow drum is repaired by Wanji hollow hole grouting technology, it needs natural curing for 48 hours. During this period, vibration and trampling are strictly prohibited.

When the concrete cracks due to various reasons, it will cause leakage, reinforcement corrosion, and the reduction of the structural durable strength. Therefore, the cracks should be repaired. For active cracks of plastic cracks and dry shrinkage cracks, treatment can be carried out after they are basically stable, or reinforcement measures can be taken after crack treatment, and pressure injection method can be used to limit the development of cracks. The low pressure glue injection repair method is to inject the low viscosity modified epoxy resin sealant into the concrete micro cracks through the glue injector, and use its high permeability and high bonding strength to repair and strengthen the concrete cracks.

Construction repair of hollowing grouting: the crack surface shall be sealed first. Then grouting repair shall be carried out.

Grouting construction repair: process flow and key points of operation: construction preparation → inspection of hollowing range → determination of drilling position → drilling construction → dust removal → embedding grouting nozzle → grouting treatment construction → inspection of grouting compactness → pulling out grouting nozzle → hole repair → surface curing (1), and confirmation of hollowing parts to be treated.

(2) The hollow position shall be drilled, the surface shall be cleaned, and the grouting nozzle shall be buried.

(3) . Grouting shall be carried out after the grouting nozzle is arranged: the grouting pressure and grouting amount shall be determined according to the specific situation of the hollow part.

(4) Pour the empty drum glue into the grouting machine container after it is prepared. Use the high-pressure grouting machine to pour the modified adhesive into the empty drum position, and close the valve immediately after proving that the grouting is full. During grouting, the grouting fluid shall be prevented from overflowing from other holes to cause waste. Confirm the completion of grouting and remove the machines and tools.

(5) Epoxy mortar is used for hole repair.

(6) It can be used normally after drying and curing for 2 days. Note: The integrity, strength, impact resistance and wear resistance of the repaired crack are enhanced. No hollowing, cracking and dusting.