Activities range from initial subjective and objective benchmarking,vehicle-level and system/component-level target setting,NVH troubleshooting and development to achieve programme targets and launch suport。

NVH Activities include:

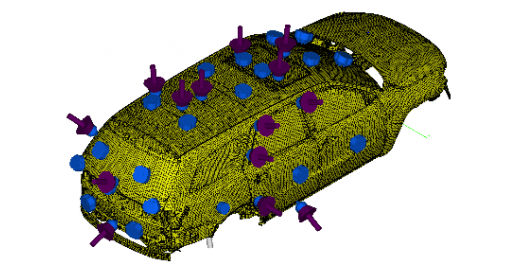

- Benchmarking activities to aid in vehicle-level target setting,along with cascading of targets down to the system and component level。

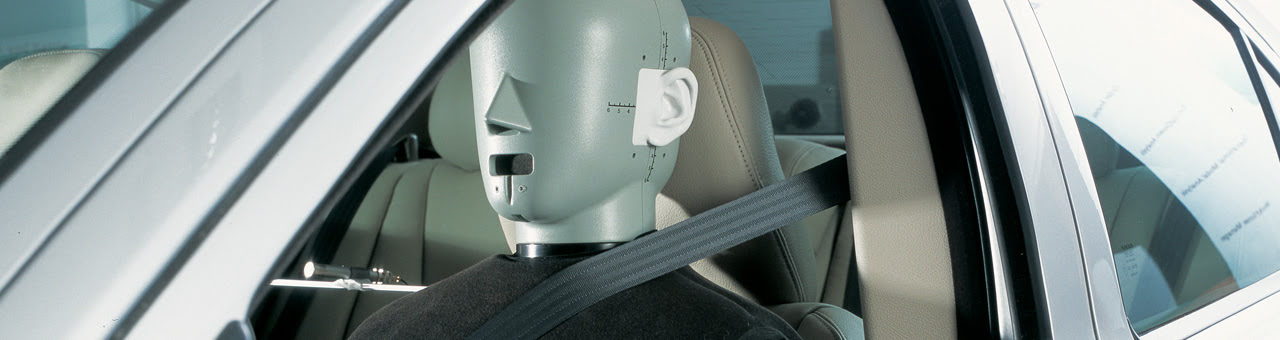

- 电力列车NVH responsibilities(acoustic and structural development,mount development,rigid-body modes,modal coupling,intake/exhaust assessments,etc.)

- 加载/交流基础hooting和countermeasure development

- (noise source identification,交通运输调度,交通运输调度

- Acoustic package optimization to achieve programme targets,utilizing both conventional methods aswell as advanced acoustic imaging techniques to streamline evalation time

- Body structure dynamic-mode assessments against programme targets to aid troubleshooting efforts and identify potential concern areas for power train noise,road noise,etc

- Support through to launch,including key driving evaluations by management and press events。

Projects include initial subjective and objective benchmarking,vehicle-level and system/component-level target setting,NVH troubleshooting and development to achieve programme targets,and launch support。

Here are some projects and project elements we have worked on with customers: