主通道

主通道

-

Acoustic Transducers -

电流和电压传感器 -

置换传感器 -

力传感器 -

加载中心 -

多组件传感器 -

压力传感器 -

Strain Sensors -

Strain Gauges -

模板传感器 -

Tilt Sensors -

Torque Sensors -

视频,视频

-

电气化访问应用程序 -

Artificial Ear -

Artificial Mouth -

Bone Conduction -

数据Acquisition -

HATS(Head and Torso Simulator) -

icrophone -

信号协调,信号协调 -

测试解决方案

主通道

-

视觉控制软件 -

Random -

Classical Shock -

时间扭曲复制 -

Sine-On-Random -

Random-On-Random -

Shock Response Spectrum Synthesis

-

源电平表 -

可视化方法 -

源完整性度量 -

Noise Dosimeter -

Hand-held Software -

S&V Hand-held Services Accessories for S&V Hand-held Services

-

多通道系统 -

单通道系统 -

Piezoelectric(Paceline) -

Press Fit Controller -

Amplifier with Display -

列车轨道 -

Industrial Electronics Accessories for Industrial Electronics

-

微型托架 -

Microphone Pre-Amplifiers -

Microphone Sets -

Hydrophones -

源源,源 -

Acoustic Calibrators -

Special Microphones -

Acoustic Transducers Accessories for Acoustic Transducers

-

Piezoelectric Charge Accelerometer -

Piezoelectric CCLD(IEPE)Accelerometers -

力传感器 -

Piezoelectric Reference Accelerometer -

Tachometer Probes -

视频载波 -

Optical Accelerometer -

Vibration Transcers Access for Vibration Transcers -

离散视频传输

-

Acoustics and Vibration -

Asset&Process监控 -

数据Acquisiton -

电能测试 -

Fatigue and Durability Analysis -

机械测试 -

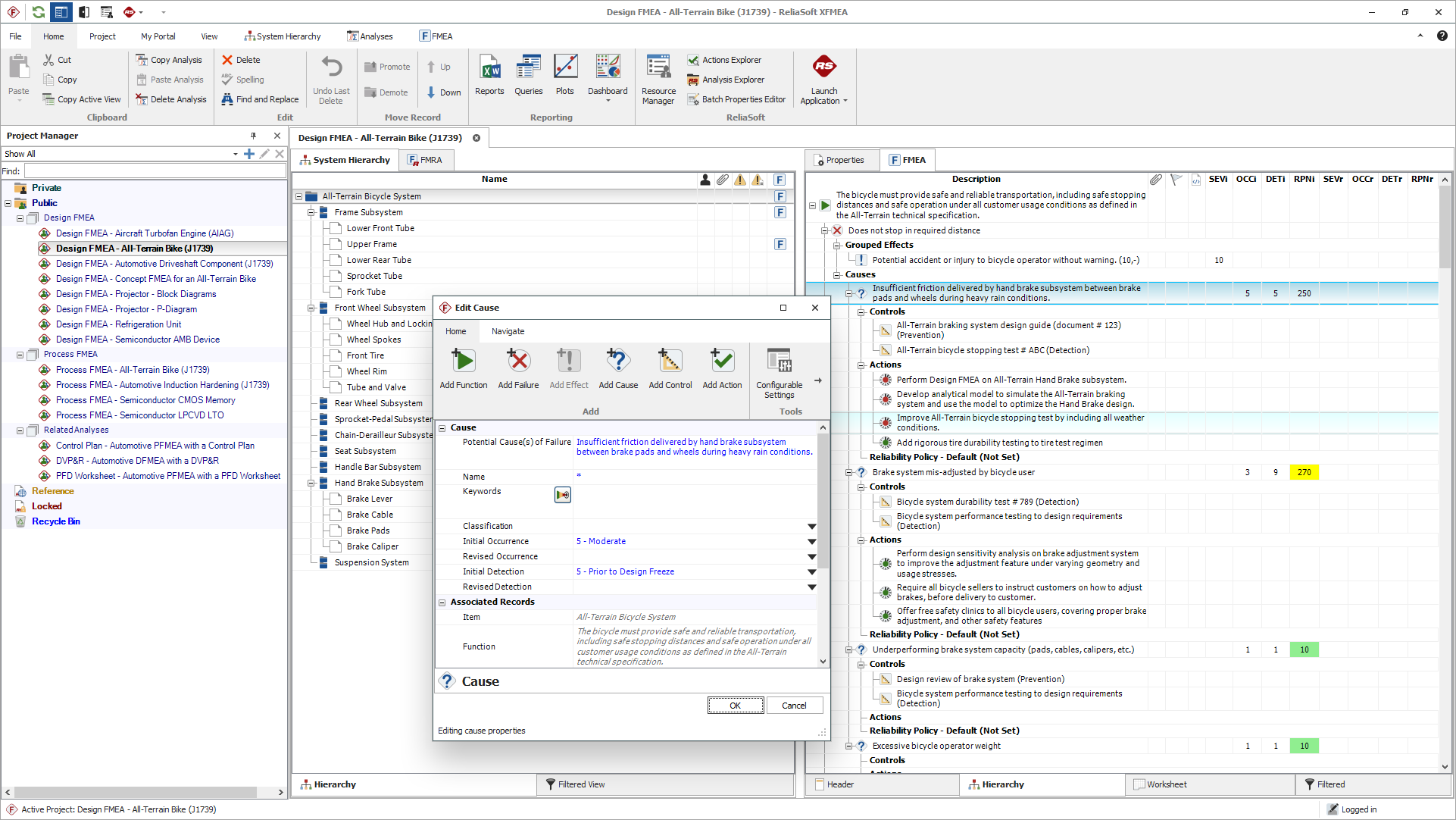

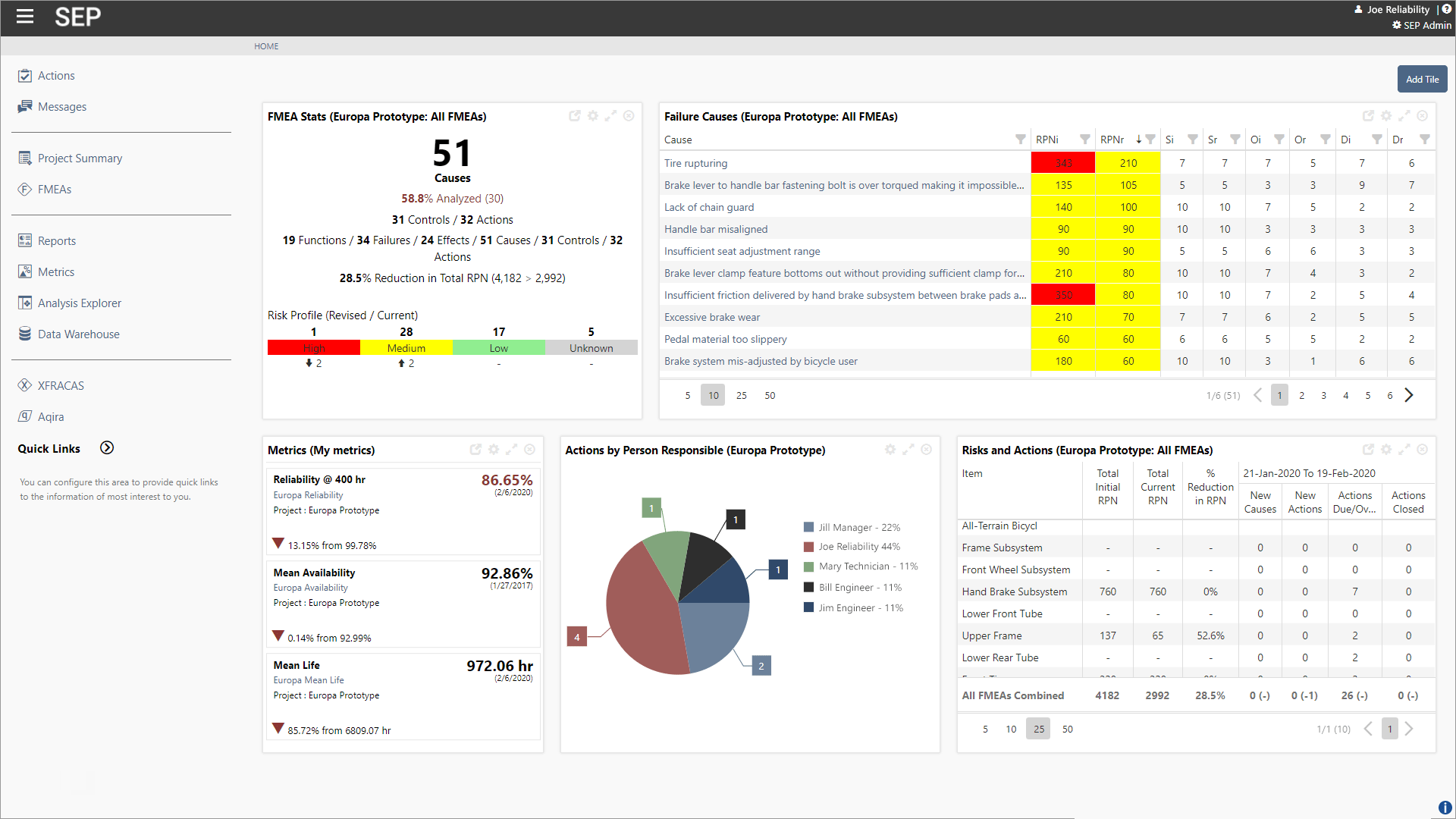

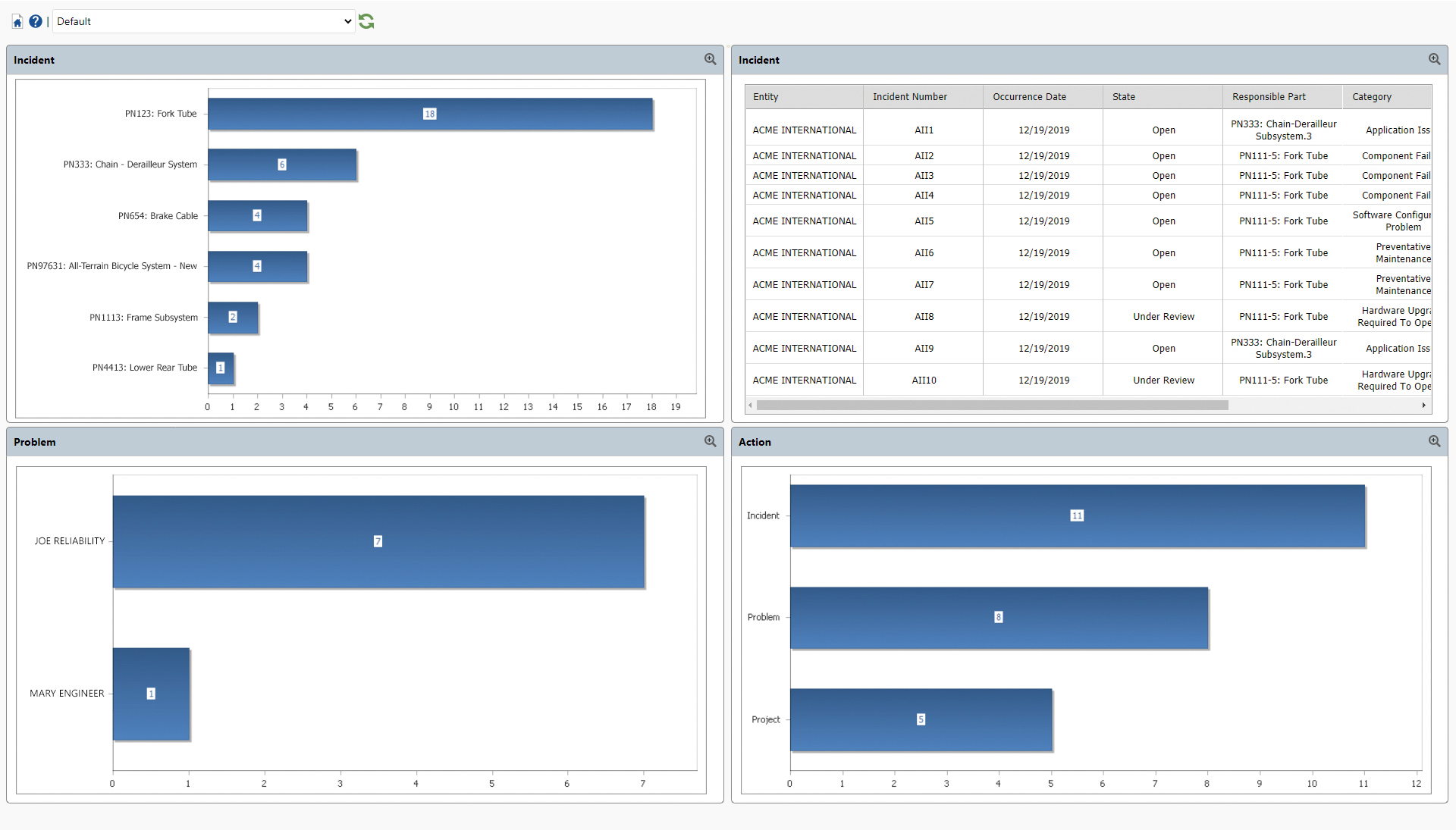

可靠性 -

加强,加强

主通道

-

测试Of Hands-Free Devices -

Smart Speaker Testing -

Speaker Testing -

Hearing Aid Testing -

Headphone Testing -

Telephone Headset and Handset Testing

-

Acoustic Holography -

Acoustic Signature Management -

地下水位测量范围 -

Wind Tunnel Acoustic Testing–Aerospace -

绞车,绞车 -

弯曲,弯曲 -

Flyover Noise Source Identification -

实时Noise Source Identification With Acoustic Camera -

源完整性映射 -

Spherical Beamforming -

产品说明

-

Shock and Drop Testing -

Environmental Stress Screening-ESS -

包装测试 -

“Buzz,Squeak and Rattle(BSR)” -

机械安全保障协议

-

操作定义图形(ODS) -

Classical Modal Analysis -

Ground Vibration Test(GVT) -

操作模块分析(OMA) -

Structural Health Monitoring(SHM) -

测试有限元集成 -

Shock Response Spectrum(SRS) -

结构动态系统

-

电子定位和可靠性检测(NEW) -

电子和信号处理设备(NEW) -

电气化机械和可拆卸性aspects(NEW) -

电气电气电气(NEW)-电气Vehicles -

“电气化:可靠性和性能” -

电气化(NEW)-交流电源分析用电气化和信号定位处理技术 -

电气(NEW)-Aplying Statical and Reliiability Techniques for Determining Battery Life in电气Vehicles

-

力计算 -

Torque Calibration -

Microphones&Preamplifiers Calibration -

Accelerometers Calibration -

预应力计算 -

置换传感器计算